Casting-body-effect-free reservoir evaluation method based on nanoparticle filling experiment

A technology of nanoparticles and evaluation methods, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, which can solve the problem of strong reservoir heterogeneity, lack of exploration and development experience, and inability to accurately evaluate reservoirs. problems such as layer gas content, to achieve the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for evaluating reservoirs without casting effect based on nanoparticle filling experiments, comprising the following steps,

[0053] Step 1: Obtain a reservoir sample of the reservoir to be evaluated;

[0054] Step 2: Observing the storage space distribution of the non-cast body effect reservoir;

[0055] Step 3: Determine the possibility of theoretical accumulation;

[0056] Step 4: Confirm the connectivity of the cast effect reservoir;

[0057] Step 5: Field experiments confirm its gas-containing property and its content.

[0058] The present invention establishes an accurate comprehensive evaluation method for non-cast body effect reservoirs through five steps and uses various analytical and experimental means, can effectively evaluate the gas-bearing properties of non-cast body effect reservoirs, and has strong operability.

[0059] The present invention is based on the evaluation of the reservoir without casting effect based on the nanoparticle experiment...

Embodiment 2

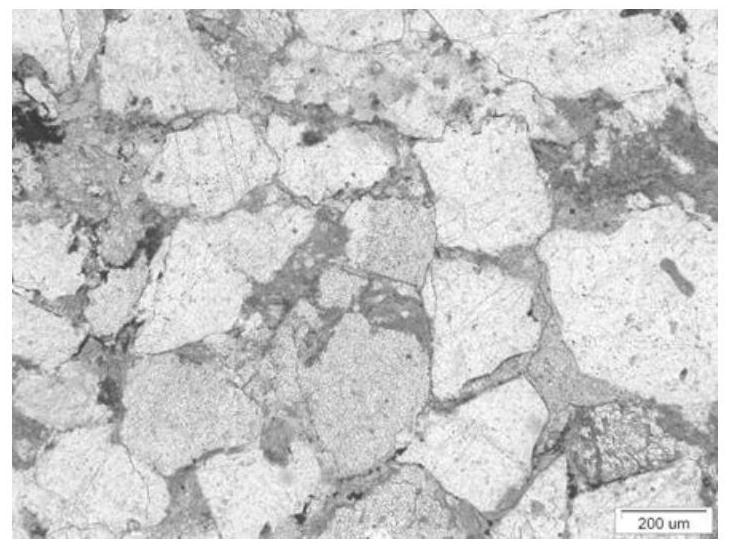

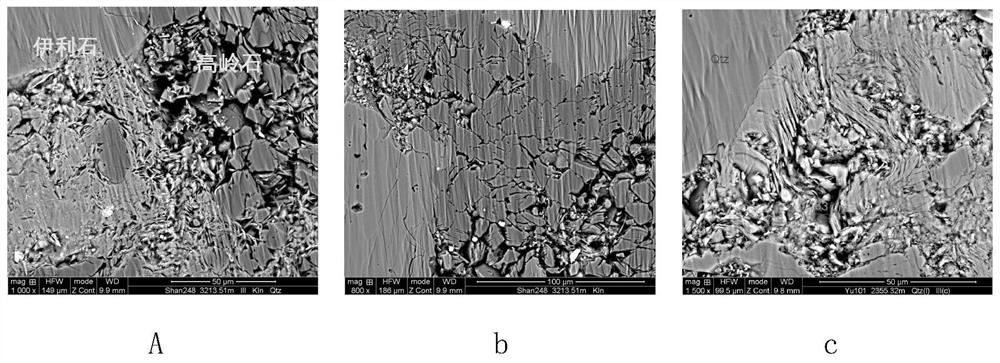

[0061] A non-cast effect reservoir evaluation method based on nanoparticle charging experiments. On the basis of the first embodiment, the specific method of the second step to observe the storage space of the non-cast effect reservoir is: for the selected The surface of the reservoir sample is polished with argon ions, and the field emission scanning electron microscope is used to observe the micro-nano microscopic reservoir space on the polished surface to determine whether the sample has an effective pore structure.

[0062] Further, the observation of the micro-nano microscopic reservoir space mainly includes the observation of the sample pores and throats, and obtaining the scanning electron microscope image of the sample and extracting the depth of information to obtain the effective pore type ratio, geometric shape, pore throat, etc. Distribution, average pore size.

[0063] Since no pores can be observed under a conventional optical microscope for samples without casti...

Embodiment 3

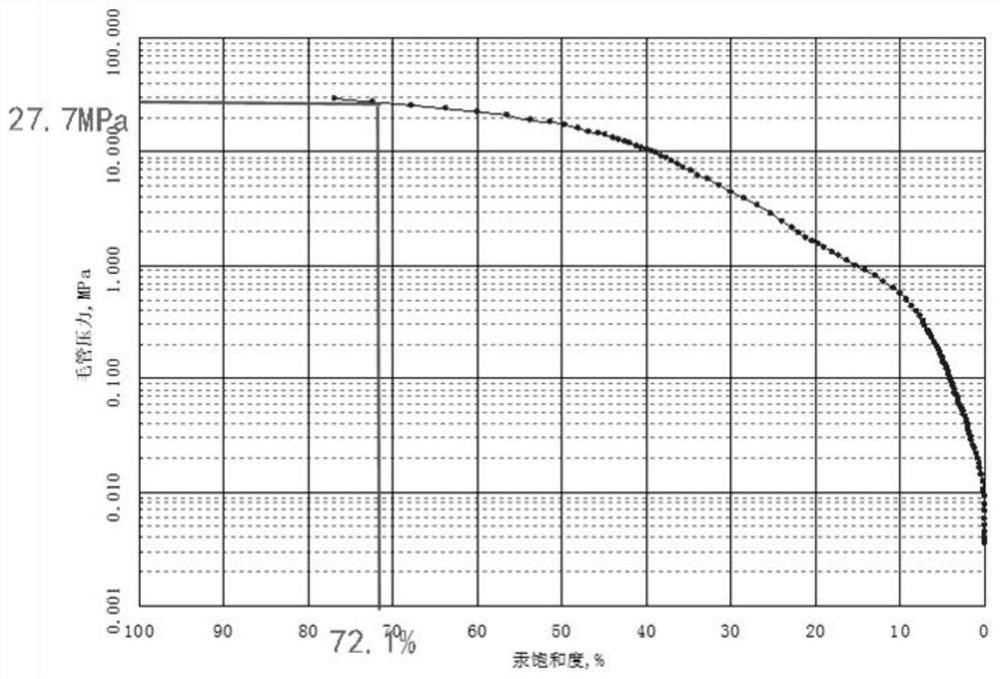

[0065] A method for evaluating reservoirs without casting effect based on nanoparticle filling experiments, based on the first embodiment: the third step to determine the possibility of theoretical accumulation is to conduct a closed coring test on the samples obtained in step one, and obtain The gas saturation and the mercury injection curve of the corresponding rock samples are used to calculate the lower limit of the effective pore throats for natural gas accumulation by using the Laplace equation (Equation 1), and combined with the size of the micropores measured in step 2 to confirm whether the micropores generally contain gas ; The specific calculation steps are as follows:

[0066] Step 1: Find the corresponding mercury saturation on the horizontal axis of the capillary pressure curve according to the gas saturation obtained from the airtight coring test, and read the corresponding mercury injection pressure on the vertical axis of the capillary pressure curve;

[0067]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com