Full-rail type railhead abrasion measuring device

A measuring device and rail head technology, which is applied in the field of guide rail measurement, can solve problems such as single measurement function, high requirements, and cost reduction, and achieve the effect of flexible adjustment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

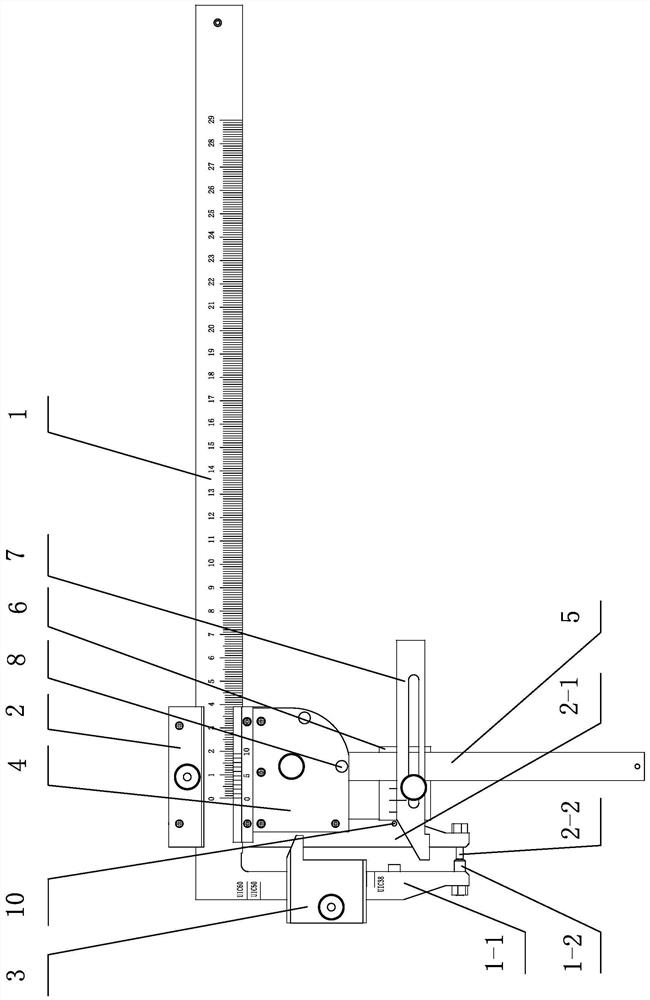

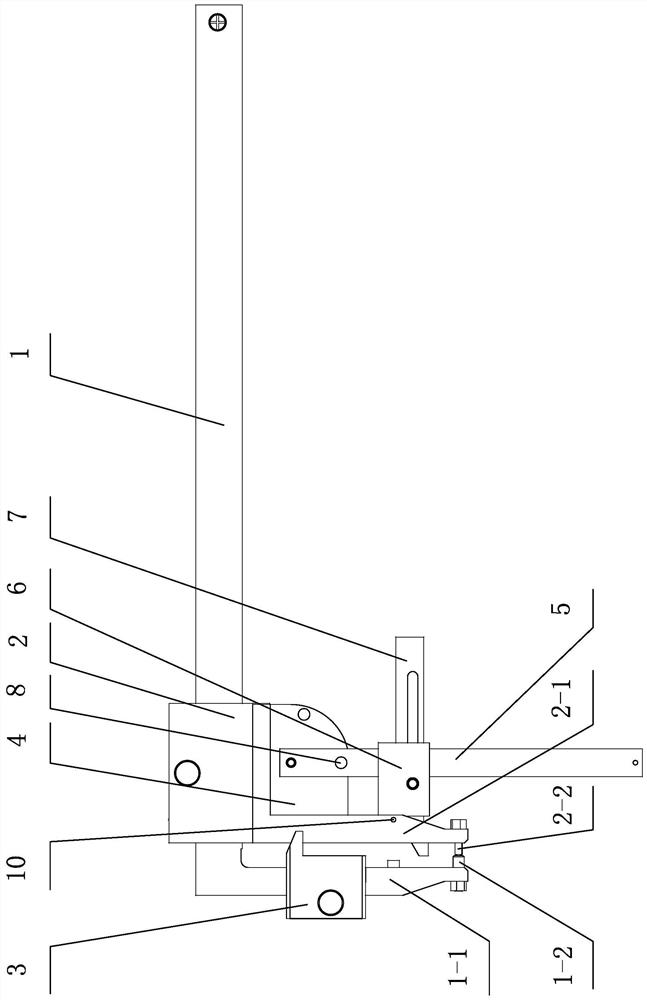

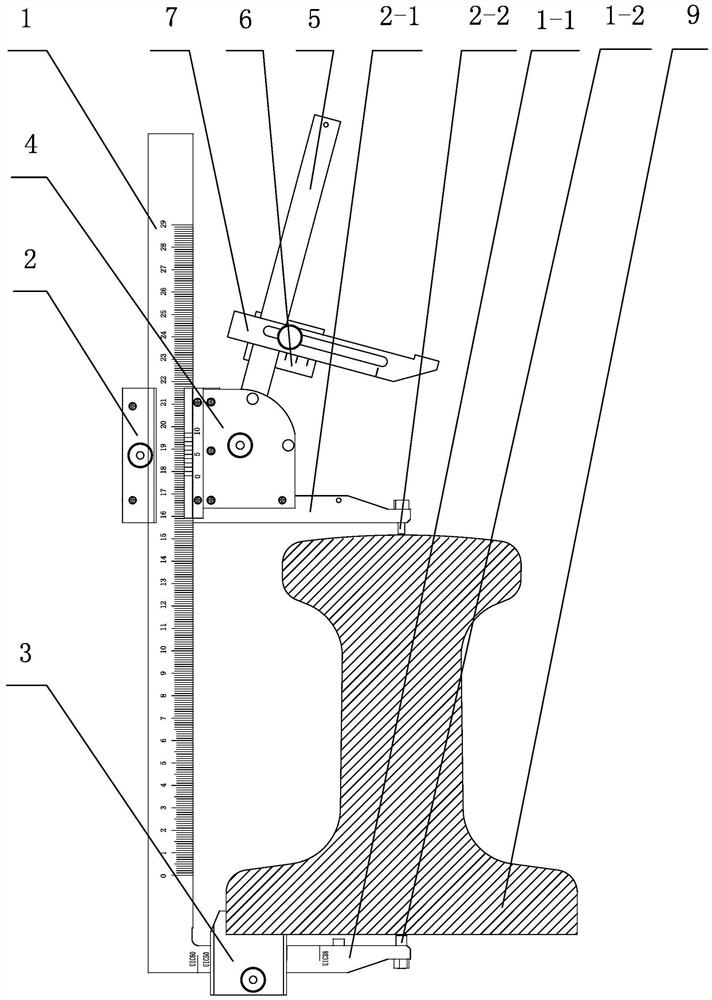

[0022] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0023] The full-rail type rail head wear measuring device of the present invention comprises a caliper frame 1 and a caliper frame 2, the caliper frame 2 is installed on the caliper body 1 and can be manually operated to slide forward and backward on the caliper body 1, so The bottom of the ruler body measuring claw 1-1 of the caliper ruler body 1 is provided with a backward ruler body measuring head 1-2, and a plurality of scale lines are engraved on the ruler body measuring claw 1-1 from top to bottom, Each scale line is the measurement position of the type UIC60 (the largest heavy rail), UIC50... UIC38 (the smallest light rail) or other types of rail 9 specified by the International Union of Railways, and the size of the UIC60, UIC50... UIC38 type rail 9 Decrementally, the bottom of the ruler frame measuring jaw 2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com