Construction method for synchronously jacking whole bridge to replace support

A technology of synchronous jacking and construction methods, applied to bridges, bridge parts, bridge construction, etc., to achieve the effects of reducing costs, ensuring safety, and operating well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

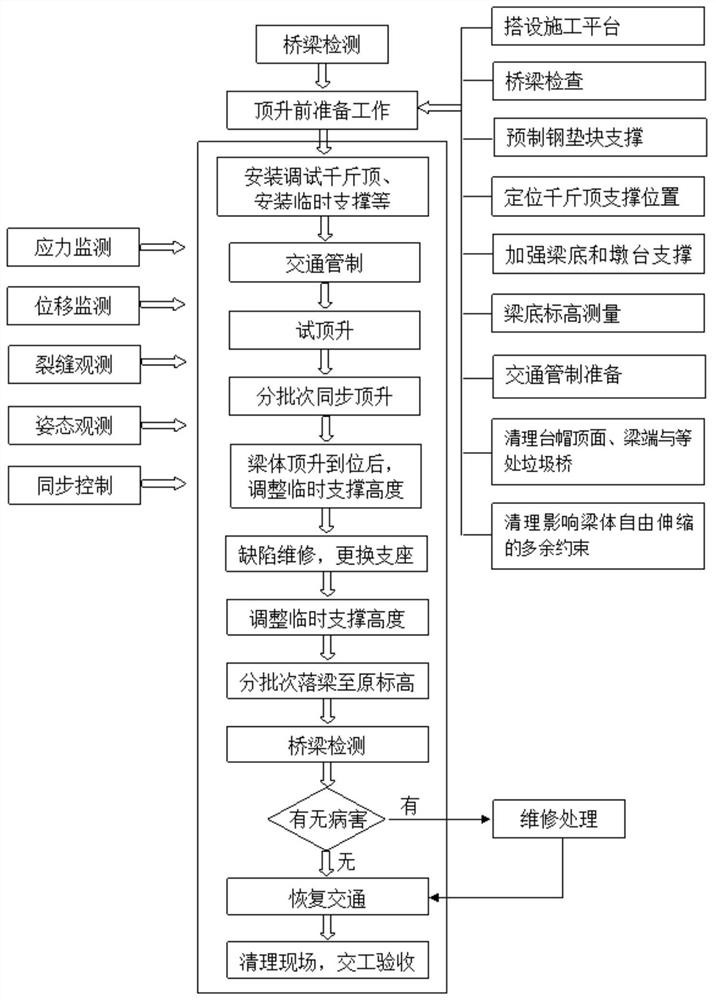

Method used

Image

Examples

Embodiment 1

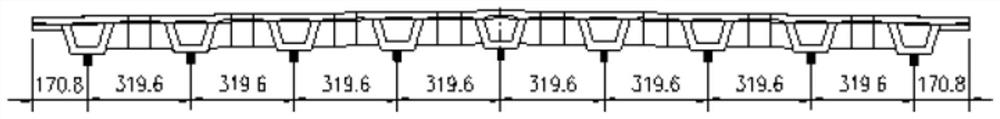

[0125] Example 1: This construction method was successfully applied to the bridge bearing replacement project of the third phase of Changfenggang Bridge on Qianjiang Road, Anqing. The project is located in Anqing City. It took only 14 days to complete the replacement task of 144 bearings, which not only greatly shortened The construction period was met, the opening to traffic requirements were realized as soon as possible, and the local traffic conditions were improved. At the same time, compared with the traditional construction method, it saves cost and resources, and creates more economic and social benefits. Moreover, this technology is reliable and operable, which improves the construction quality of bridge bearing replacement and plays an important role in ensuring the overall safety of the bridge structure. Sex is also very important.

Embodiment 2

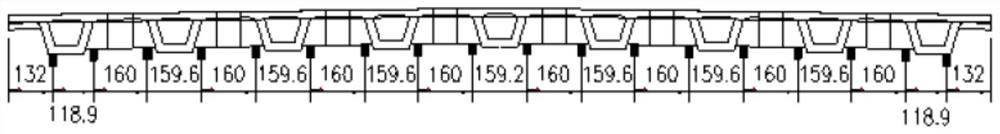

[0126] Example 2: This construction method was successfully applied to the bridge support replacement project in the Ruian viaduct repair project of G104 Ruian section. The project is located in Ruian City. It took only 13 days to complete the replacement task of 112 supports, which was shorter than the planned construction period. 8 days, laying a solid foundation for the early opening to traffic. At the same time, compared with the traditional construction method, it saves cost and resources, and creates more economic and social benefits. Moreover, this technology is reliable and operable, which improves the construction quality of bridge bearing replacement and plays an important role in ensuring the overall safety of the bridge structure. Sex is also very important.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com