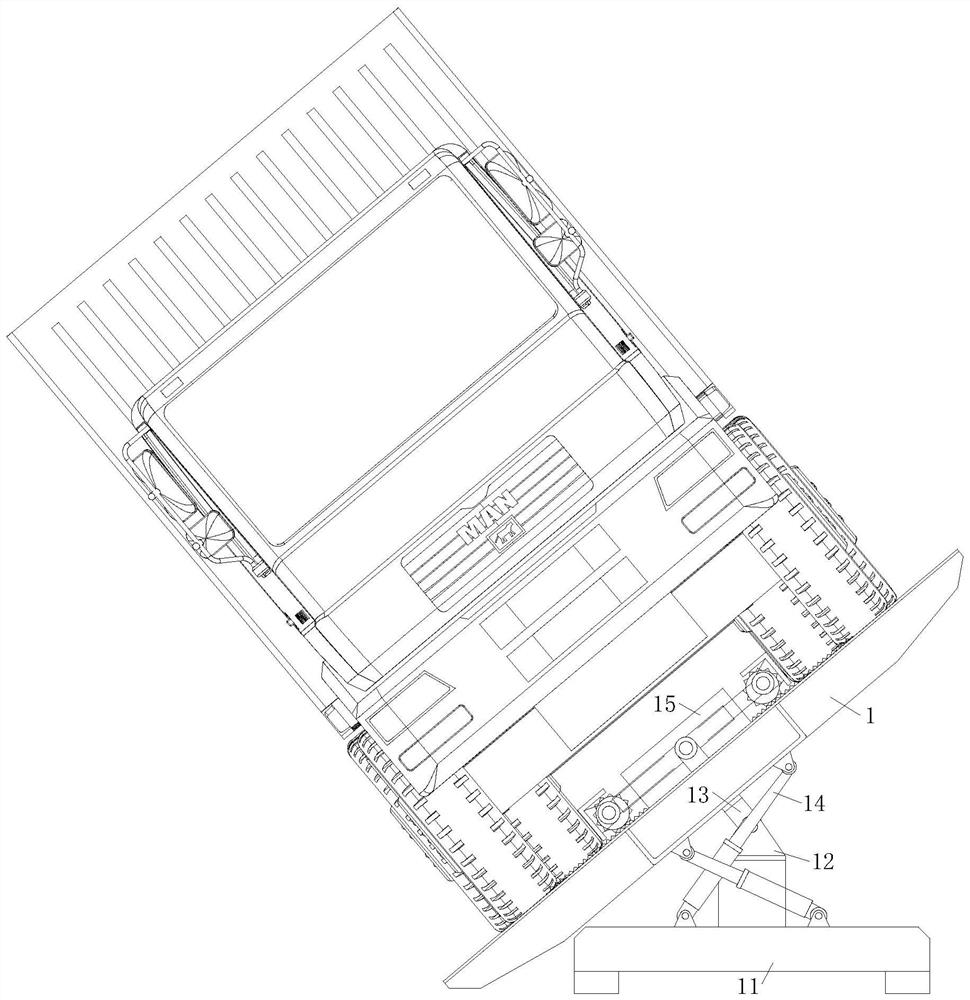

Two-side tipping type car unloader

A technology for unloaders and axles, applied in the field of tipping unloaders on both sides, can solve problems such as tire and wheel damage, and achieve the effects of reducing pressure, reducing excessive pressure, and increasing load support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

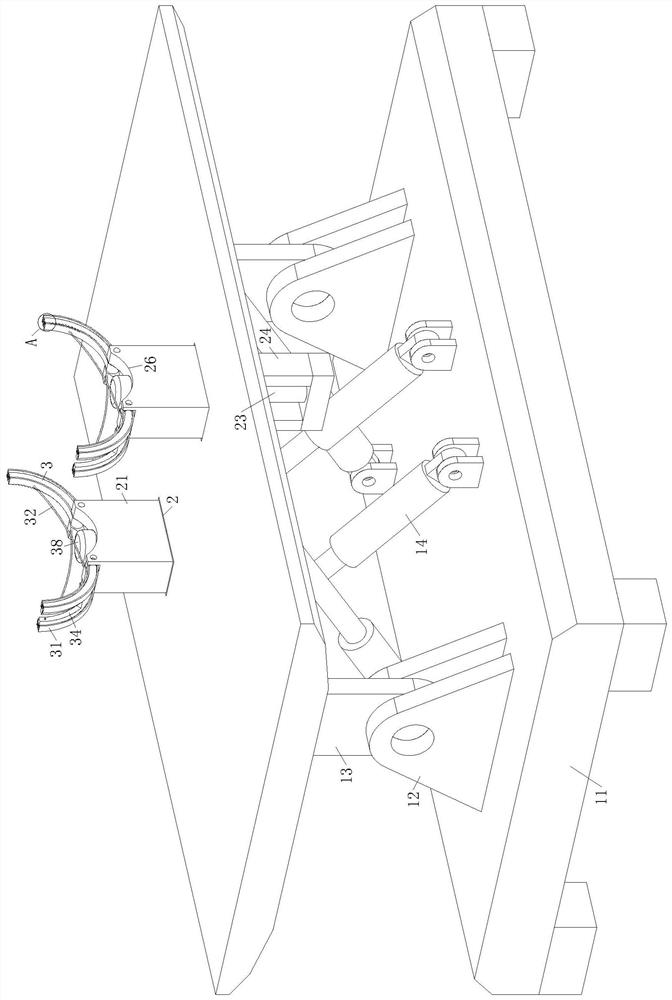

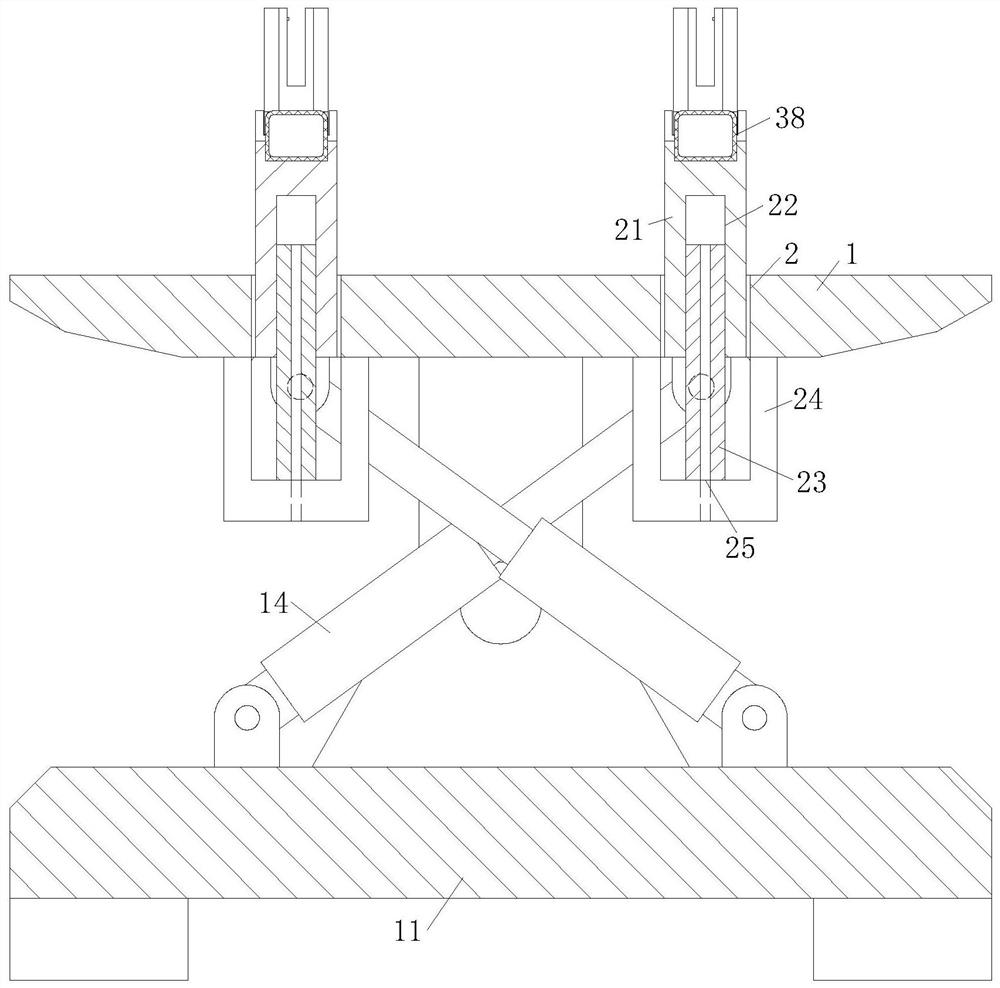

[0025] As an embodiment of the present invention, arc-shaped No. 1 splint 3 and No. 2 splint 31 are respectively hinged on the top of support block 21 at both ends of the arc-shaped groove 26; Connected with steel wire 32, the steel wire 32 is arranged in a cross shape, and the end of the steel wire 32 close to the support block 21 is fixedly connected with the support block 21; when the support block 21 is lifted, the steel wire 32 drives the No. 1 splint 3 and the No. 2 splint 31 to clamp the vehicle Bridge, to further increase the stability of the car when unloading; when the support block 21 resists and jacks up the axle, the axle squeezes the steel wire 32, and then the steel wire 32 drives the No. 1 splint 3 and the No. 2 splint 31 to close and clamp the car bridge, increasing the fixing stability of the support block 21 to the vehicle axle, and then transferring the supporting force of the tire to the vehicle axle to the support block 21, the first splint 3 and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com