Stainless steel die for manufacturing shell structure of household electric appliance

A shell structure, the technology of the manufacturer, applied in the direction of manufacturing tools, forming tools, metal processing equipment, etc., can solve the problems of low work efficiency, reduced product processing accuracy, easy accumulation of surplus materials, etc. material, to ensure the effect of processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

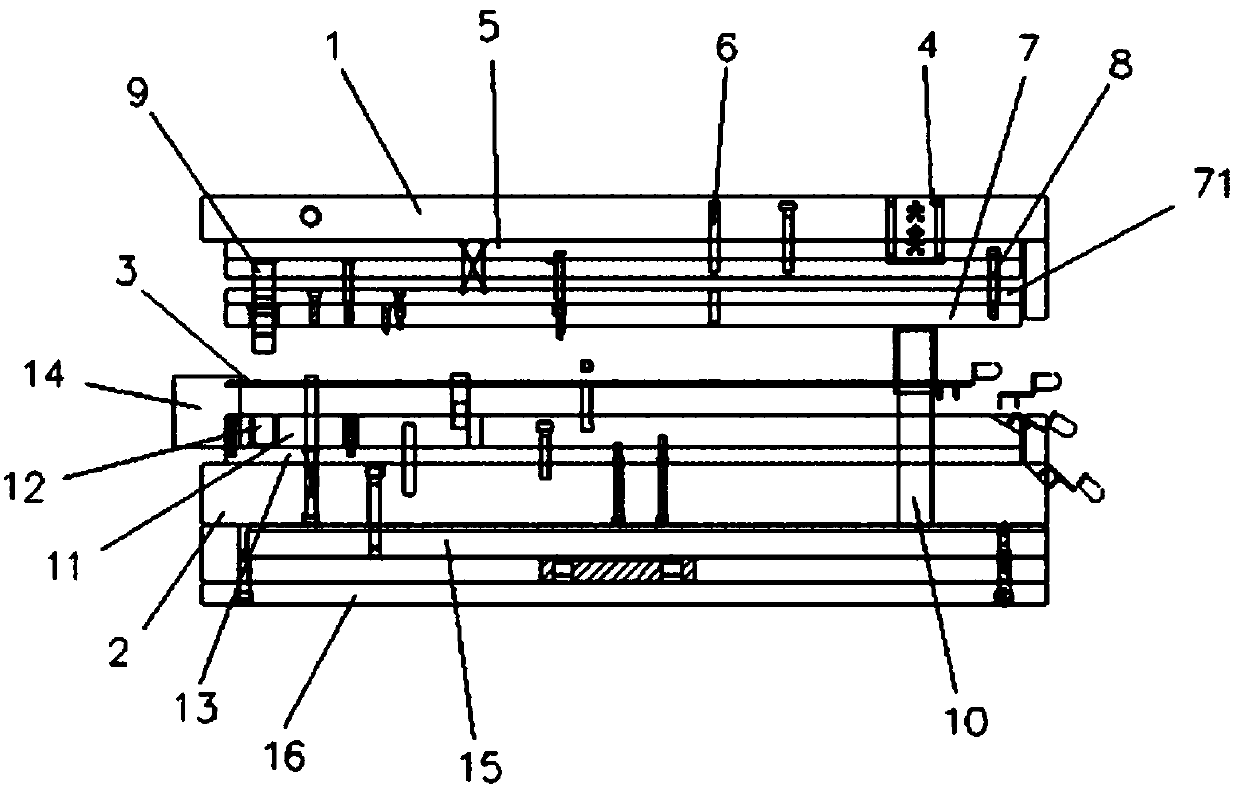

[0014] The following is attached figure 1 , the specific implementation manner of the present invention will be further described in detail, so as to make the technical solution of the present invention easier to understand and grasp.

[0015] A stainless steel mold for making the housing structure of household electrical appliances, such as figure 1 As shown, it comprises a upper mold bottom plate 1, a lower mold bottom plate 2 and a thick plate 3, the thick plate 3 is located in the middle of the upper mold bottom plate 1 and the lower mold bottom plate 2, and the right end of the upper mold bottom plate 1 is provided with a water tank 4 , the lower end of the upper mold bottom plate 1 is provided with an inner backing plate 5, the inner backing plate 5 is double-layered, and a stud 6 is arranged between the inner backing plate 5 and the upper mold bottom plate 1, through which the stud 6 The inner backing plate 5 and the upper mold bottom plate 1 can be fixed with studs. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com