A cutting board reinforcing groove slotting device

A technology for fastening devices and cutting boards, which is applied to slotting machines, clamping devices, and mortising machines, etc., which can solve the problems of low work efficiency, cumbersome operation, and laborious work, and achieve the effect of convenient operation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

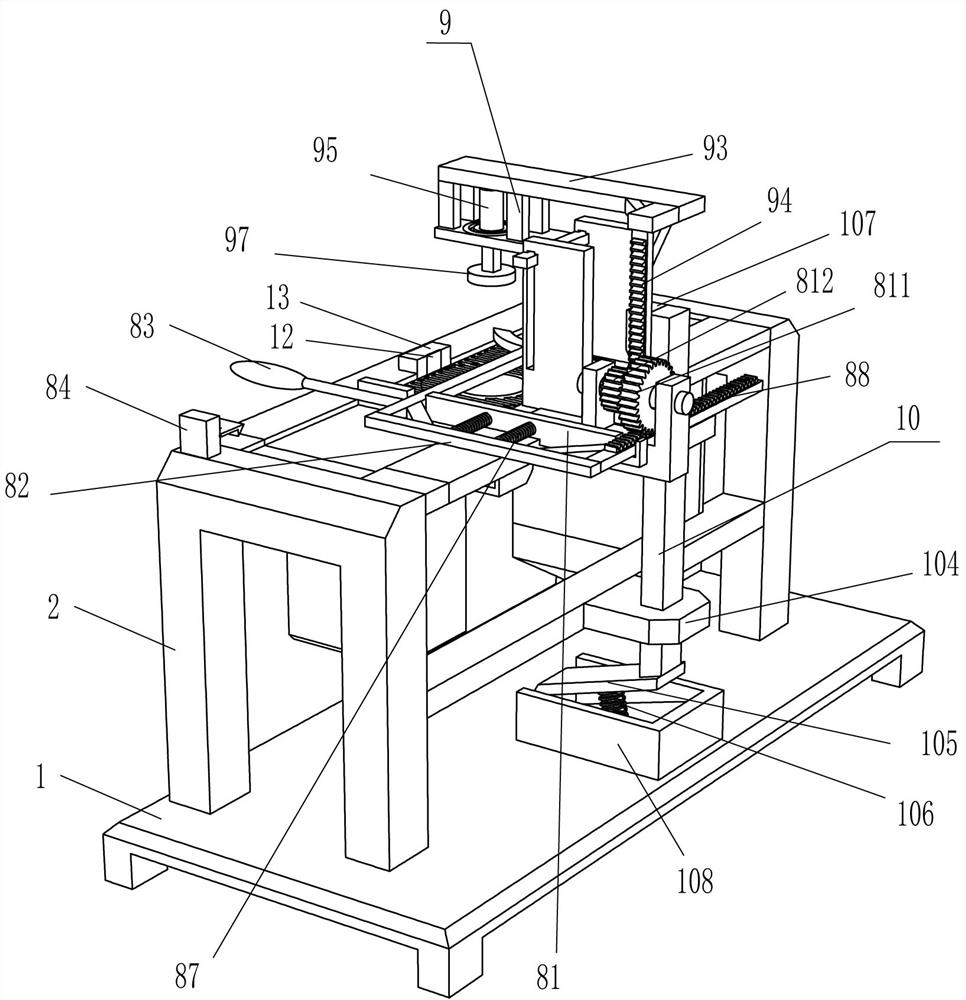

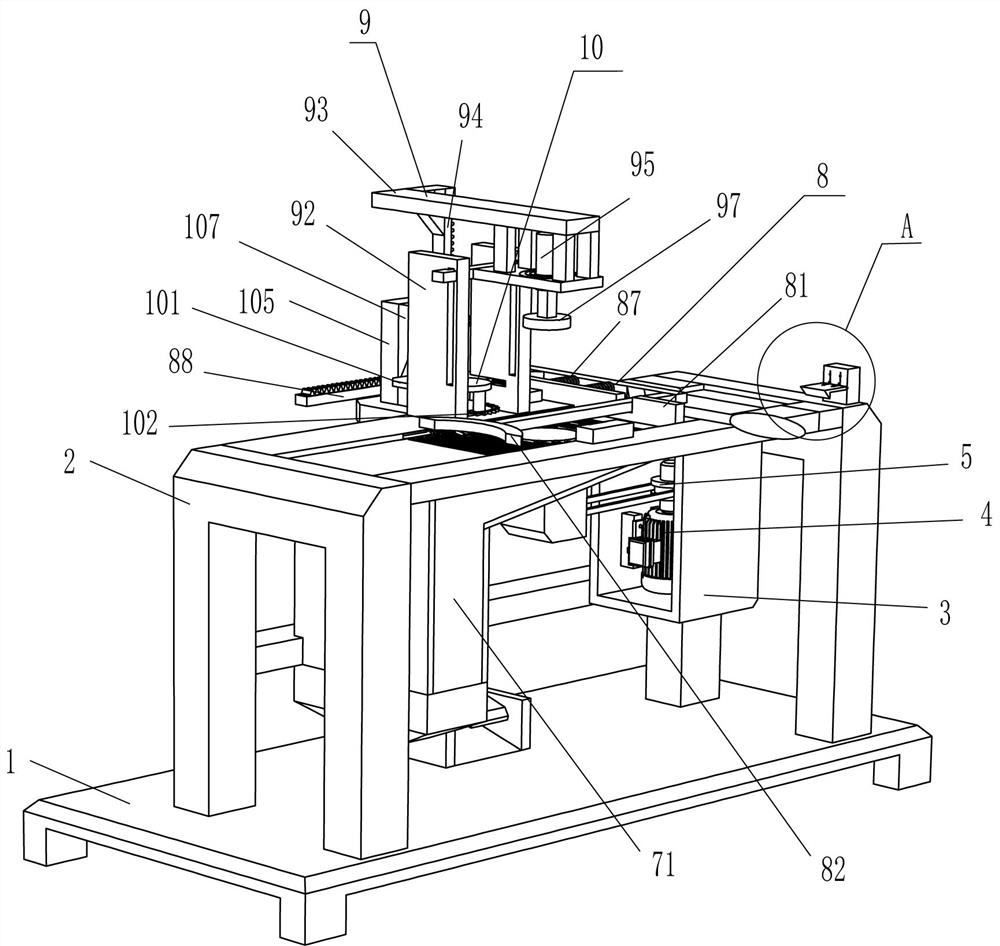

[0026] A cutting board reinforcing groove slotting device, such as Figure 1-Figure 6 As shown, it includes a base 1, a workbench 2, a bracket 3, a gear motor 4, a transmission assembly 5, a first rotating shaft 6, a contact pad 7, a hopper 71, a pushing device 8, a fastening device 9 and a slotting mechanism 10 , the top of the base 1 is fixedly connected with the workbench 2, and the middle of the upper front side of the workbench 2 is connected with the first rotating shaft 6 in a rotational manner, and the top of the first rotating shaft 6 is fixedly connected with the contact pad 7, and the contact pad 7 is embedded in the workbench 2, a bracket 3 is fixedly connected to the right front part of the inner top of the workbench 2, and a geared motor 4 is installed in the middle of the inner bottom of the bracket 3, and a transmission assembly 5 is connected between the output shaft of the geared motor 4 and the lower circumferential direction of the first rotating shaft 6. C...

Embodiment 2

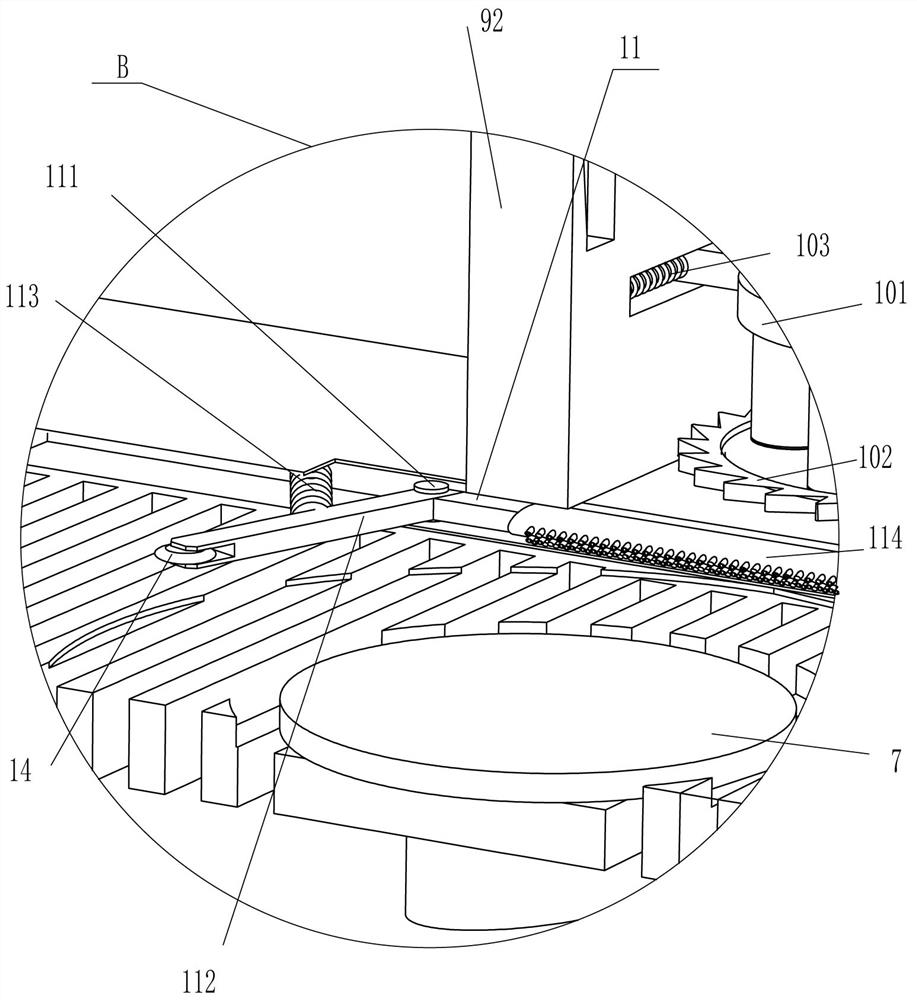

[0035] On the basis of Example 1, such as image 3 and Figure 5 As shown, it also includes a dust removal device 11. The dust removal device 11 includes a third rotating shaft 111, a contact rod 112, a fifth spring 113 and a hair brush 114. The upper part of the workbench 2 is connected with a rotating type on the left side of the rear side. Three rotating shafts 111, the third rotating shaft 111 is affixed with a contact rod 112, the right end of the contact rod 112 is affixed with a brush 114, and a fifth spring 113 is connected between the outer left side of the contact rod 112 and the inside of the workbench 2.

[0036] When the push rod 82 drives the cutting board to move to the left and disengage from the contact pad 7, the cutting board contacts the contact rod 112, and the cutting board drives the front part of the contact rod 112 to swing to the left, the fifth spring 113 compresses, and the front part of the contact rod 112 swings to the left so that The right part...

Embodiment 3

[0038] On the basis of embodiment 1 and embodiment 2, such as figure 2 , image 3 and Figure 5 As shown, sandpaper 12 and installation block 13 are also included, and installation block 13 is affixed to the middle part of the front side of the outer top of workbench 2, and sandpaper 12 is affixed to the middle part of the rear side of installation block 13.

[0039] It also includes a guide wheel 14, and the front end of the contact rod 112 is rotatably equipped with the guide wheel 14.

[0040] After the cutting board was compressed, the cutting board was also in contact with the sandpaper 12, and then when the cutting board was rotated and slotted by the saw disc 102, the sandpaper 12 removed the burrs that occurred after the slotting. In this way, the outer circumferential groove of the cutting board can be made smoother.

[0041] When the chopping block moved to the left, the chopping block drove the contact rod 112 front portion to swing to the left by the guide whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com