Automatic spinning forming device for powder liner

A technology of spinning forming and medicine type cover, which is applied in the direction of engine components, other manufacturing equipment/tools, turbines, etc., can solve the problems of non-conformity with occupational health, low production efficiency of ordinary hydraulic presses, noise pollution, etc., and reduce personnel participation. and labor intensity, the protection of personnel occupational health, the effect of reducing noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

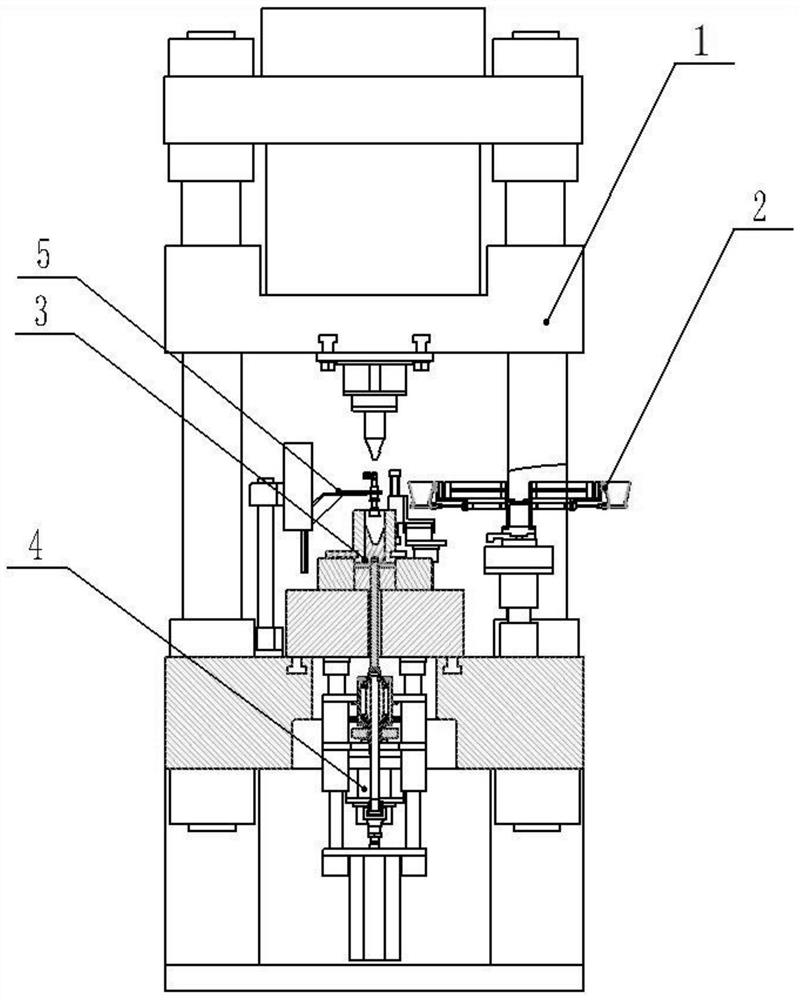

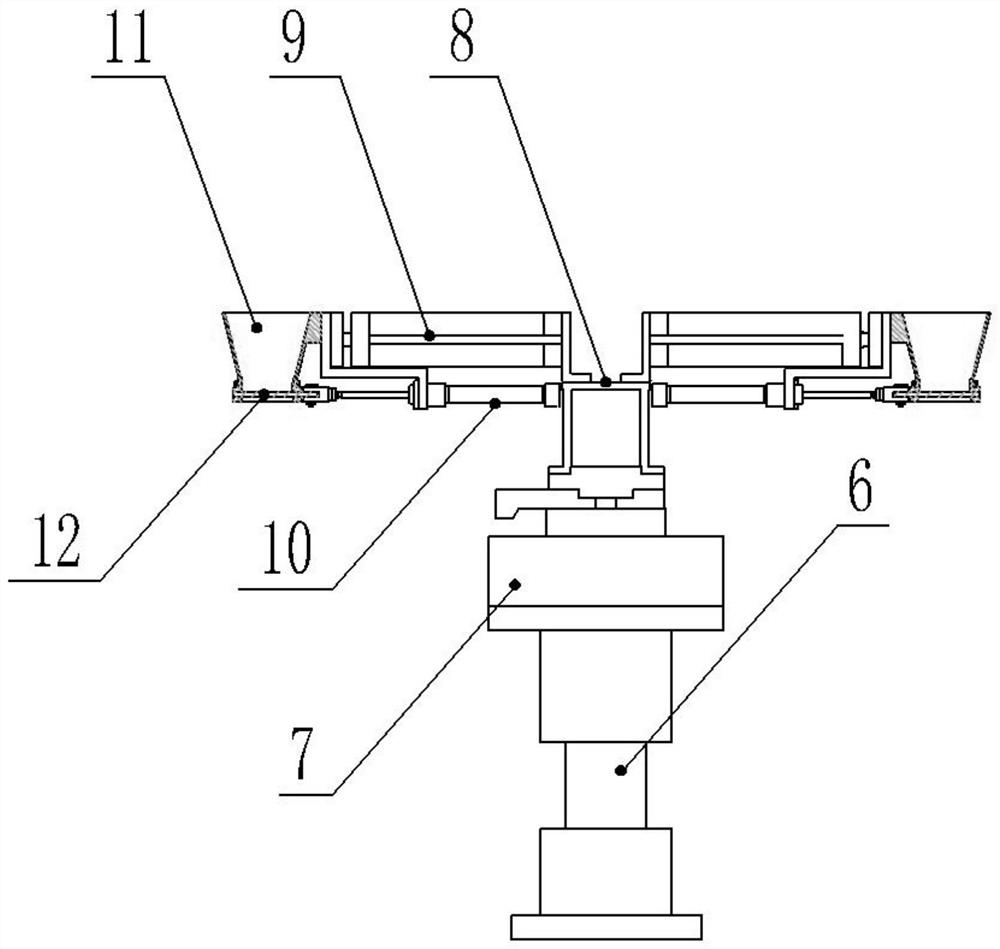

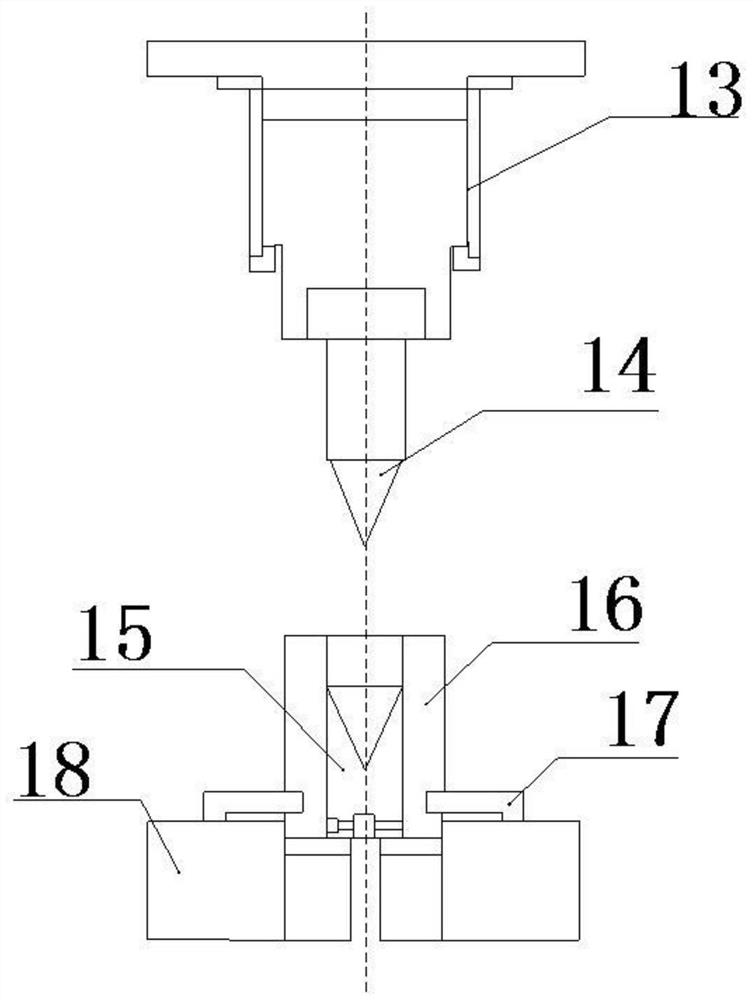

[0037] Such as Figure 1 to Figure 5 As shown, an automatic spinning forming device for a powder medicine cover, including a four-column hydraulic press 1, a powder feeding assembly 2, a mold assembly 3, a powder spinning and ejection assembly 4, and a cover removal assembly 5;

[0038] The mold assembly 3 is installed at the center of the workbench of the four-column hydraulic press 1; the powder rotating and ejecting assembly 4 is installed directly below the mold assembly 3, and is connected with the mold assembly 3 through a connecting rod; the powder feeding assembly 2 and the cover assembly 5 are respectively Installed on both sides of the workbench, the discharge port of the powder feeding assembly 2 is located directly above the center of the mold assembly 3, and the cover taking assembly 5 is used to take out the molded drug cover.

[0039] The four-column hydraulic press 1 is a three-beam four-column type, the hydraulic system is an oil-electric servo system, the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com