Soil detection sampler based on environmental detection

A soil detection and environmental detection technology, applied in the direction of sampling devices, etc., can solve the problems that soil sampling is not easy enough, soil is not easy to clean, etc., and achieves the effects of convenient installation and disassembly, simplified operation, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

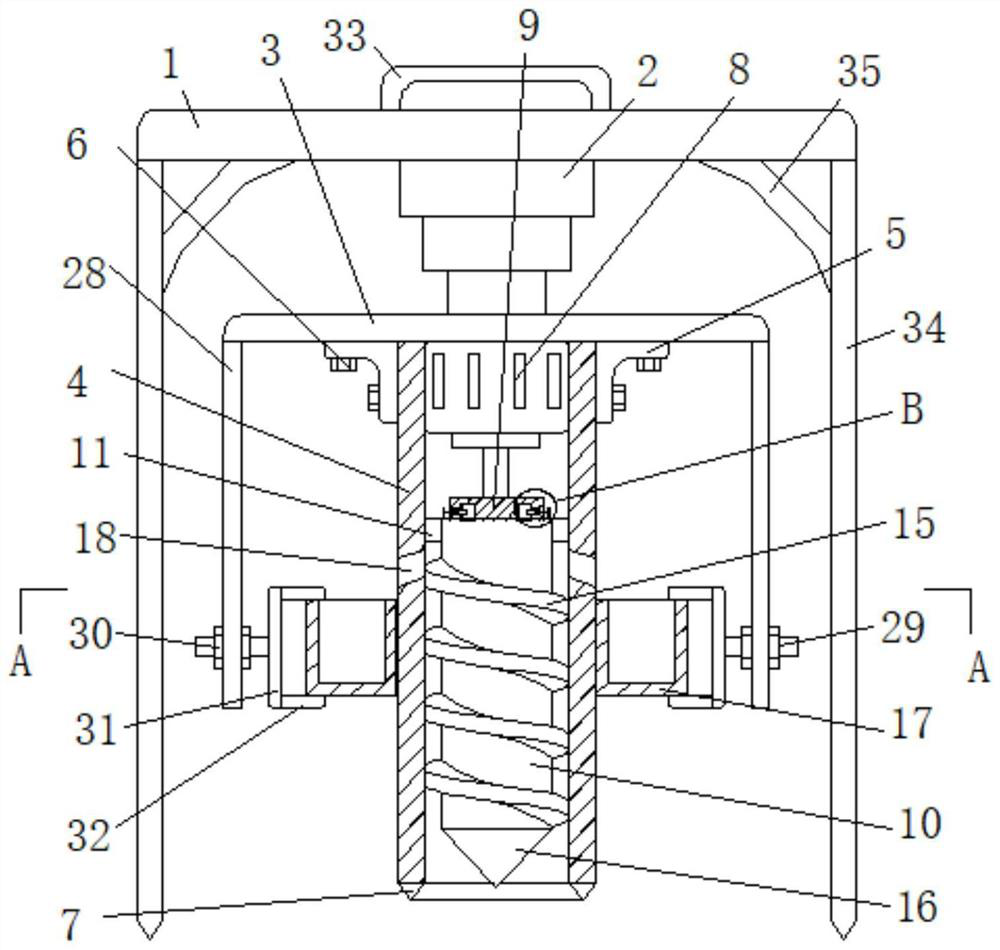

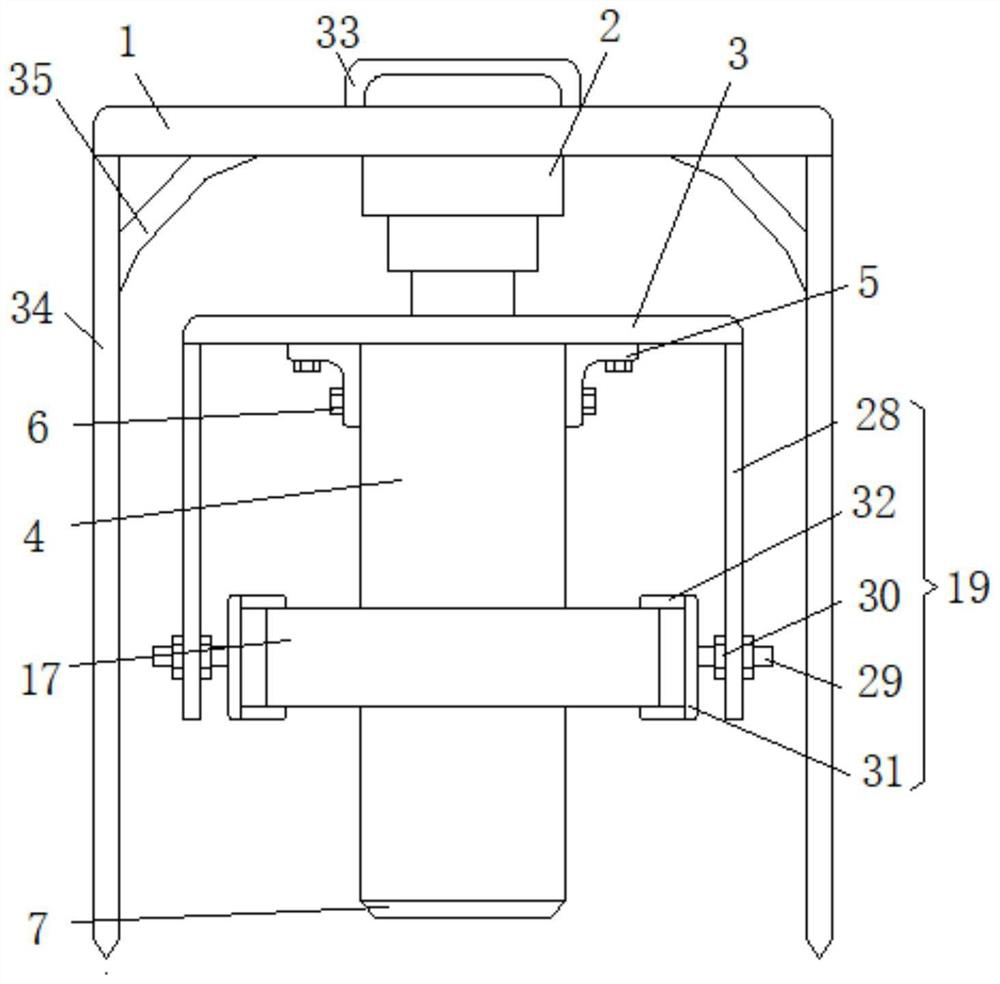

[0030] Embodiment one, such as Figure 1-7As shown, a sampler for soil detection based on environmental detection includes a horizontally arranged substrate 1, a cylinder 2 is fixedly connected to the bottom surface of the substrate 1, and a first connecting plate 3 arranged horizontally is fixedly connected to the bottom end of the cylinder 2. The bottom of the connecting plate 3 is provided with a material taking tube 4, the top of the material taking tube 4 is in contact with the bottom surface of the first connecting plate 3, and a plurality of connecting pieces 5 are arranged on the outside of the taking material tube 4, the cross section of the connecting piece 5 is L-shaped, the first Both the connecting plate 3 and the retrieving cylinder 4 are in contact with the connecting piece 5, the first connecting plate 3 and the retrieving cylinder 4 are fixedly connected to the connecting piece 5 through the mounting screw 6, and the bottom end of the taking cylinder 4 is fixed...

Embodiment 2

[0031] Embodiment two, such as figure 1 , 6 , 7, the clamping mechanism 14 includes a groove 20 arranged in the clamping groove 13, a sliding plate 21 is slidably connected to the groove 20, and a locking block 22 is fixedly connected to the side of the sliding plate 21 facing the port of the groove 20, The side of the sliding plate 21 facing away from the port of the groove 20 is fixedly connected with a first pull rod 23, and the first pull rod 23 is arranged horizontally. The outer part of the second connecting plate 9 is fixedly connected with a second pull rod 24, the second pull rod 24 is vertically arranged, and the side of the sliding plate 21 facing away from the port of the groove 20 is fixedly connected with the inner wall of the groove 20 by a spring 25, and the clamping column 12 There is a card slot 26 that matches the block 22, and the inner port of the groove 20 is fixedly connected with a limiter 27. The limiter 27 is ring-shaped, and the limiter 27 is sleeve...

Embodiment 3

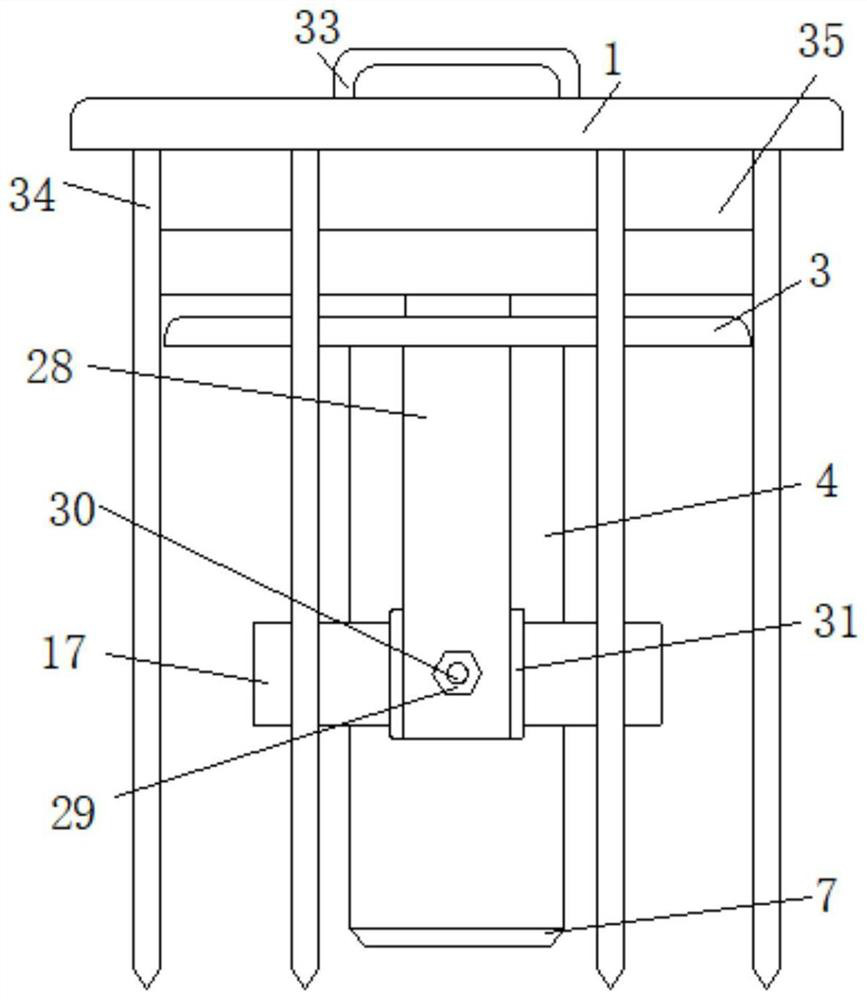

[0032] Embodiment three, such as Figure 1-5 As shown, the fixing mechanism 19 includes a support plate 28 fixedly connected to the bottom surface of the first connecting plate 3, the support plate 28 is vertically arranged, and the bottom end of the support plate 28 is horizontally provided with a screw rod 29, and the screw rod 29 runs through the support plate 28 and is slidably connected with it. , both sides of the support plate 28 are provided with nuts 30, and the two nuts 30 are threadedly connected with the screw rod 29, and the two nuts 30 are in contact with the support plate 28, and the end of the screw rod 29 near the receiving tube 17 is fixedly connected with a first abutment plate 31, the first abutment plate 31 is vertically arranged, the upper and lower ends of the inner side of the first abutment plate 31 are fixedly connected with the second abutment plate 32, and the two second abutment plates 32 are all arranged horizontally, and the second abutment plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com