Integrated mounting bracket, wheel train structure of engine and engine

A technology for installing brackets and engines, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc. It can solve the problems of affecting the weight of the whole machine, arranging air-conditioning compressors, and inconvenient installation, so as to achieve effective use of power resources and reduce the cost of installation parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

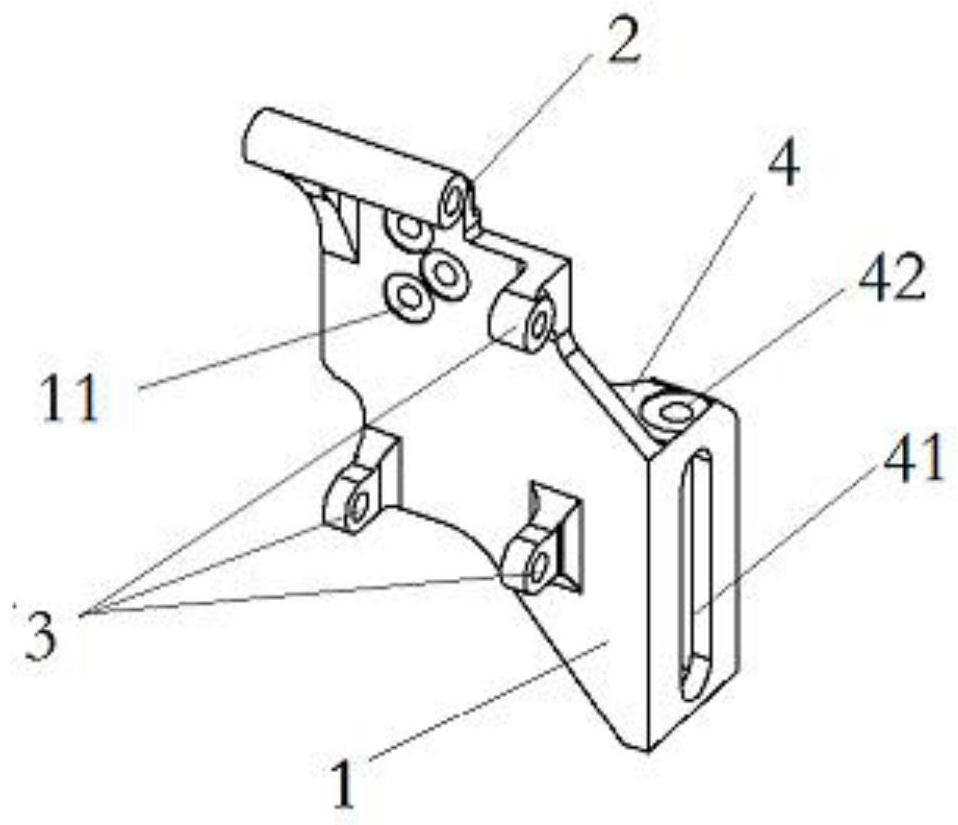

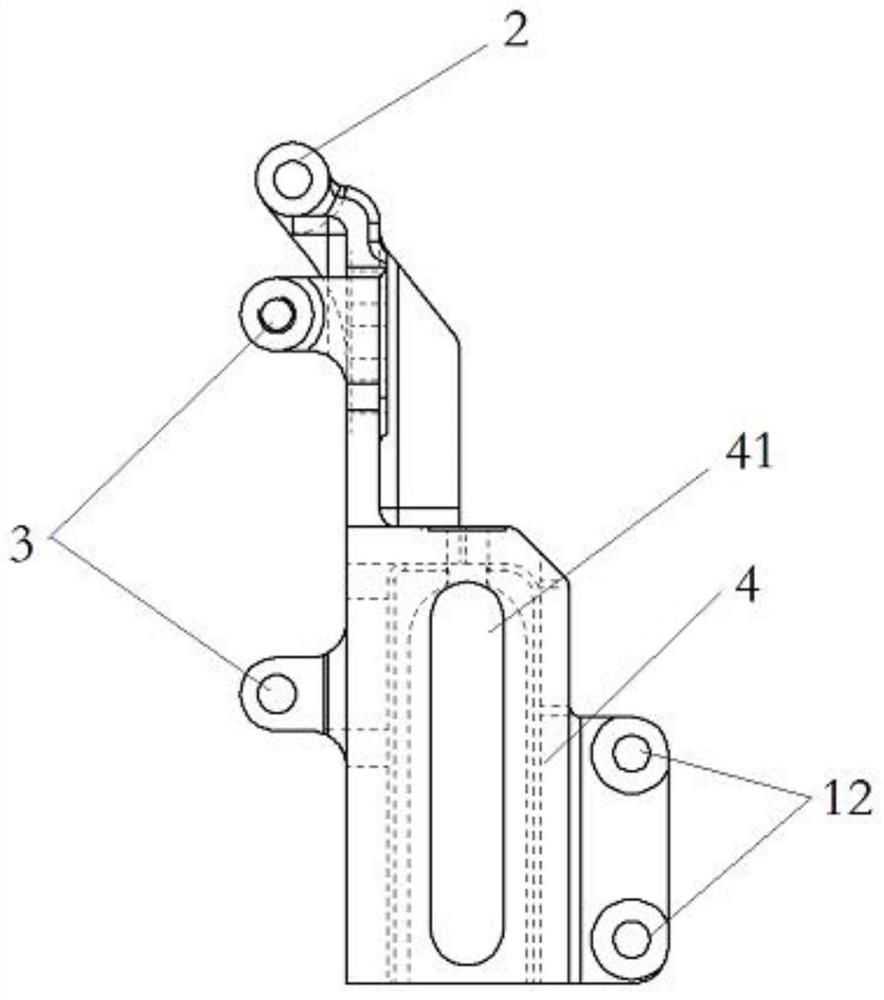

[0028] like figure 1 , figure 2 As shown, an integrated mounting bracket includes a bracket body 1 , a first connection part, a second connection part and a third connection part. The front side of the bracket body 1 is used for installing a generator and an air conditioner compressor.

[0029] The front of the bracket body 1 is provided with a first bracket installation hole 11, which is installed on the engine by fixing bolts;

[0030] The first connecting part is located at the front top of the bracket body 1, and the first connecting part is a generator installation hole 2 for connecting with a generator through bolts;

[0031] The second connection part is located on the front of the bracket body 1, and the second connection part is an air conditioner compressor installation hole 3 for connecting with the air conditioner through bolts;

[0032] The third connection part is a boss 4 located on the side of the bracket body 1 and protruding to the rear. The boss is provid...

Embodiment 2

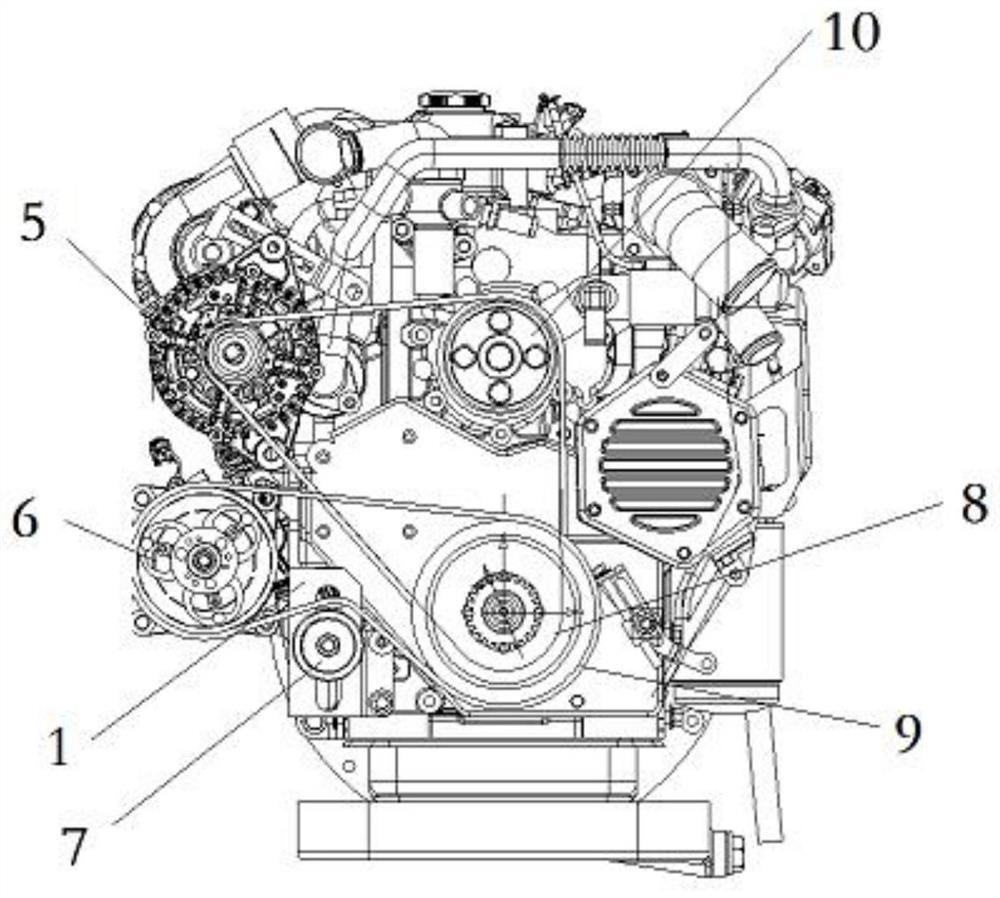

[0037] like image 3 Shown, a kind of engine wheel train structure, on the basis of embodiment one,

[0038] Including generator 5, air conditioner compressor 6, tension pulley 7, crankshaft shock absorber 8, additional pulley 9, water pump 10 and corresponding transmission belt, wherein

[0039] The integrated mounting bracket and the connected generator 5 and air-conditioning compressor 6 are located on the left side of the engine;

[0040] Tension pulley 7, crankshaft shock absorber 8, additional pulley 9 and water pump 10 are located at the front side of the engine,

[0041] The additional pulley 9 and the crankshaft shock absorber 8 are arranged coaxially;

[0042] The generator 5, the crankshaft shock absorber 8 and the water pump 10 form an inner wheel train;

[0043] The air-conditioning compressor 6, the additional pulley 9 and the tension pulley 7 form an outer wheel train.

[0044] The load of the air conditioner compressor 6 is relatively high, and it is requir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com