Washing machine

A washing machine and washing water technology, which is applied in the field of self-cleaning washing machines and washing machines, can solve the problems that the wave wheel and the inner barrel cannot be solved, and achieve the effect of ensuring the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

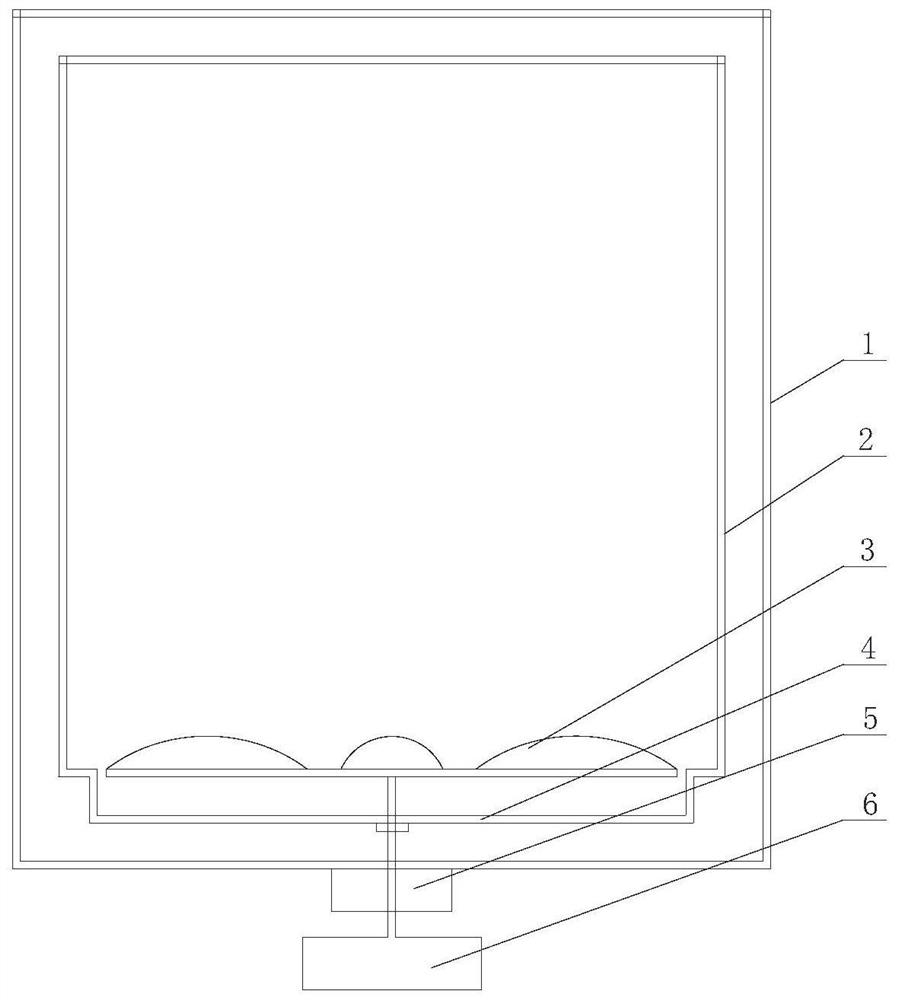

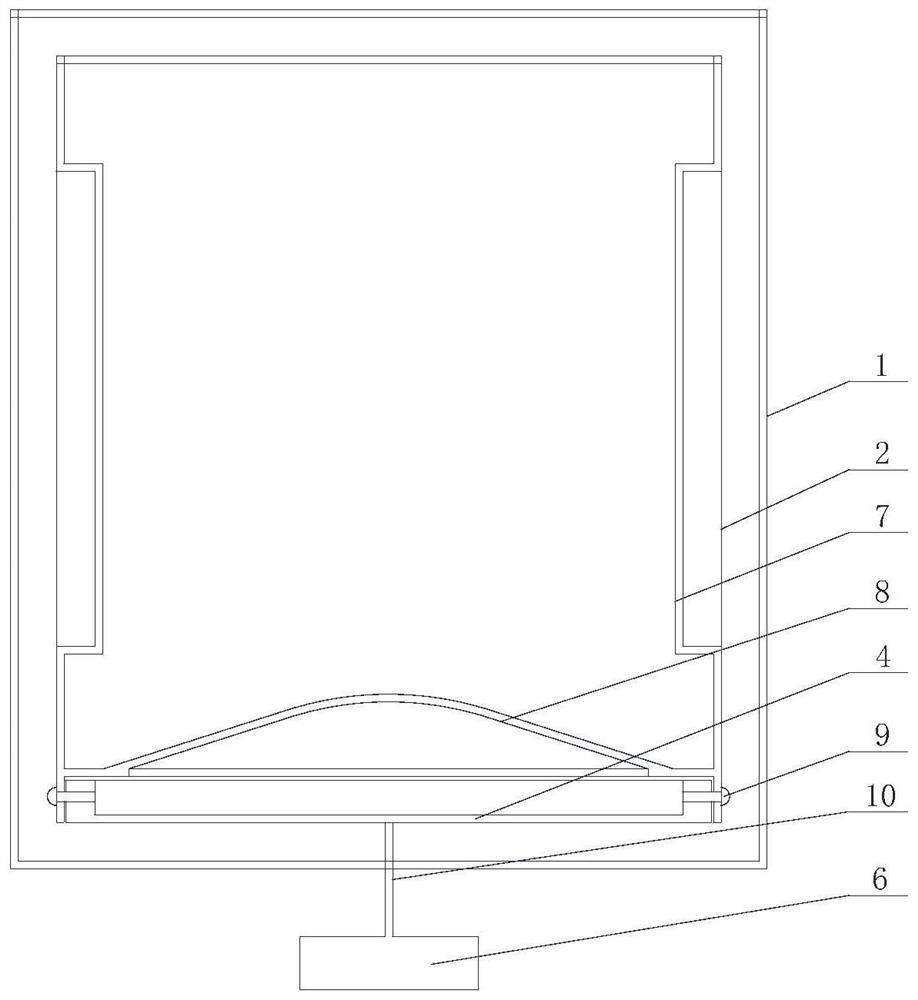

[0037] Such as Figure 2-Figure 4 As shown, this embodiment provides an inner tub of a washing machine, including a tub bottom 4 and a tub body 2, the tub body 2 has a closed area, and the closed area and the tub bottom 4 together form a water holding chamber that can independently hold washing water. The inner surface of the barrel bottom 4 is sealed or integrally formed with a barrel bottom protrusion 8 that protrudes toward the interior of the inner barrel, and / or the inner surface of the barrel body 2 is sealed and assembled or integrally formed with a barrel protrusion 7 that protrudes toward the interior of the inner barrel .

[0038] In the washing machine inner tub of this embodiment, the barrel body 2 is designed so that the inner tub can independently hold washing water during washing / rinsing, avoiding water storage between the inner tub and the outer tub, and solving the problem of dirt and dirt between the inner tub and the outer tub question.

[0039] In additio...

Embodiment 2

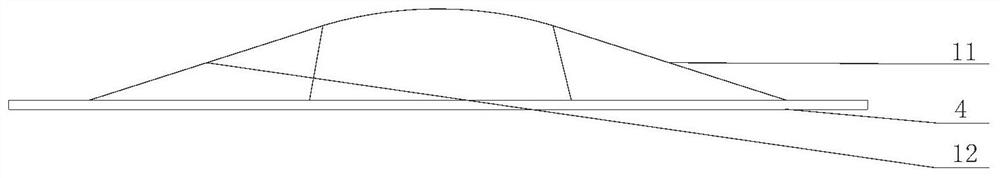

[0076] Such as Figure 5 , Image 6 and Figure 7 As shown, a washing machine in this embodiment includes an inner tub that can independently hold washing water during the washing process, and the inner surface of the bottom 4 of the inner tub is sealed or integrally formed with a bottom protrusion 8 protruding toward the inside of the inner tub. The bottom 4 of the inner tub is provided with a drain port 14, and the washing machine also includes a drain sealing device, the drain sealing device includes a sealing mechanism that can block and seal the drain port and a driving mechanism that drives the sealing mechanism to open / close the drain port.

[0077] Further, the sealing mechanism described in this embodiment includes a blocking component 24 and a supporting component 26, the supporting component 26 is fixedly installed at the bottom of the inner tub and extends to the drain, and the blocking component 24 is relatively slidably installed on the supporting component : ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com