Twisted-pair cage type hydrate continuous reaction device

A reaction device and hydrate technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of insufficient conversion of micro droplets, increase the gas-liquid contact area, stuck stirring paddle, etc., to promote efficient and rapid generation. , The effect of increasing the gas-liquid contact area and increasing the degree of dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

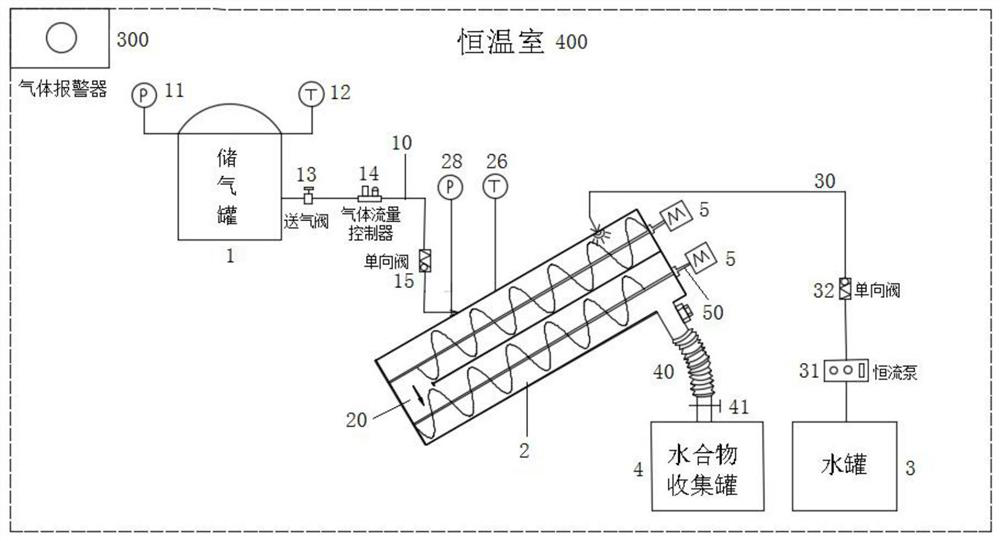

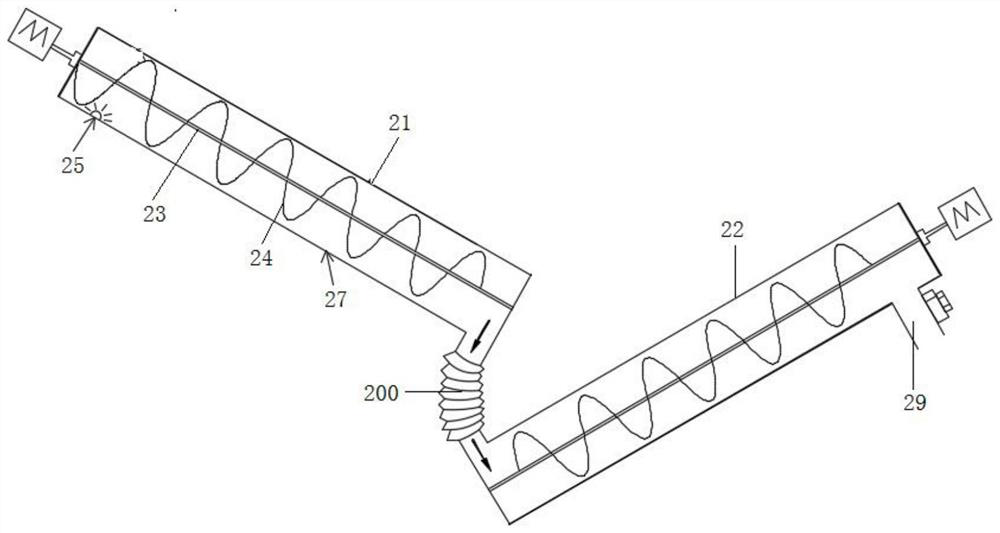

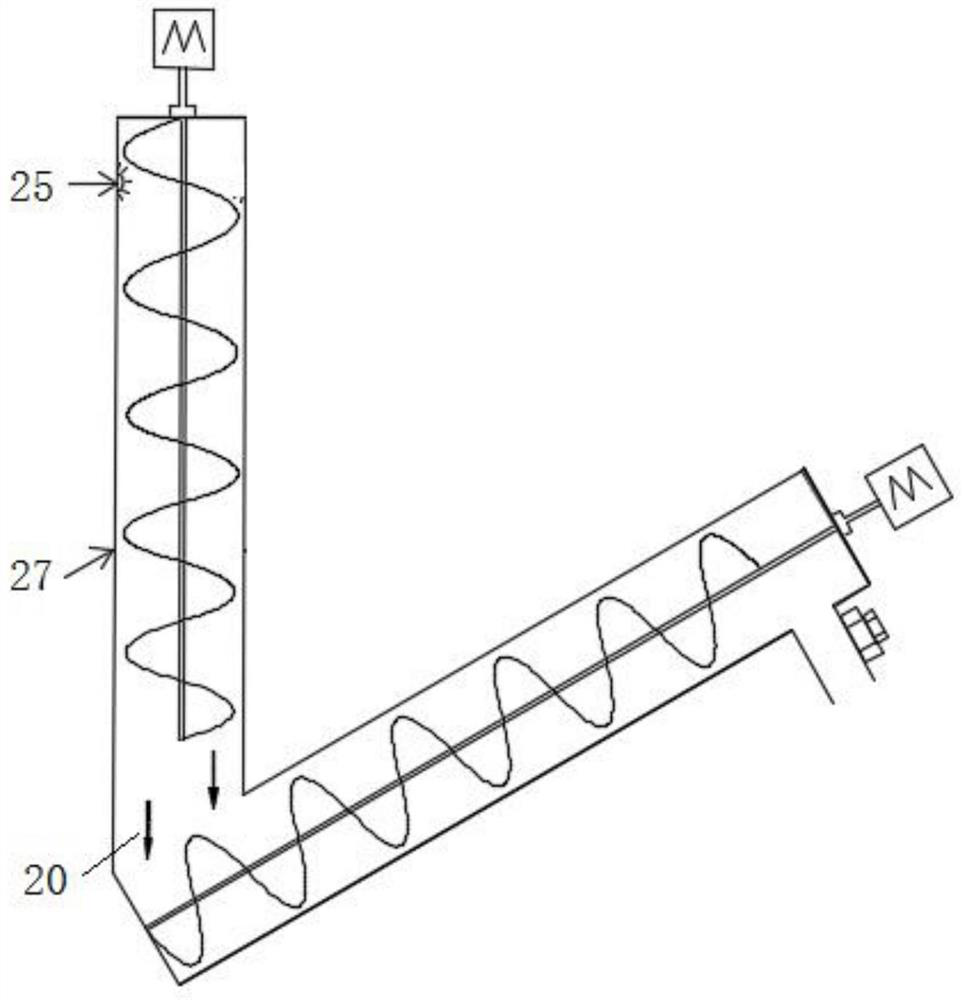

[0017]The main structure of the twisted cage type hydrate continuous reaction device involved in this embodiment includes a gas storage tank 1, a twisted cage reaction kettle 2, a water tank 3, a hydrate collection tank 4 and a motor 5; the gas storage tank 1 passes through the gas supply pipe The road 10 is connected with the twisted cage reactor 2, the gas storage tank 1 is provided with a No. 1 pressure sensor 11 and a No. 1 temperature sensor 12, and the gas supply pipeline 10 is provided with an air supply valve 13 and a gas flow controller in sequence along the flow direction of the medium. 14 and No. 1 one-way valve 15; the twisted cage reactor 2 is connected to the water tank 3 through the water supply pipeline 30, and the water supply pipeline 30 is provided with a constant flow pump 31 and a No. 2 one-way valve 32 in sequence along the flow direction of the medium; The twisted cage reactor 2 is flexibly connected to the hydrate collection tank 4 through the bellows 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com