Method and device for automatically stacking plain glass

An automatic stacking and glass technology, applied in transportation and packaging, conveyor objects, furnaces, etc., can solve problems such as low transfer efficiency and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 plane glass stacking method

[0045] The automatic stacking method of flat glass comprises the following sequential steps:

[0046] (1) Place the L-shaped bracket 1 directly in front of the end position of the conveyor belt 2, and the glass 3 is transmitted from the head end of the conveyor belt to the end position by a plurality of parallel conveyor belts 2 spaced horizontally and stops, with the end as the end point 4 of parallel conveying; see Figure 4 As shown, the glass 3 is again horizontally moved by the conveyor belt for a distance Sn;

[0047] (2) The support plate 6 fixed with several suction cups 5 in the interval of the rear section of the adjacent conveyor belt rises, and the suction cups 5 hold the lower surface of the glass 3,

[0048] (3) The support plate is centered on the end near the end point, and rotates from horizontal to vertical and slightly off the L-shaped bracket 1. The end surface of the glass 3 is adjacent to the horizontal s...

Embodiment 2

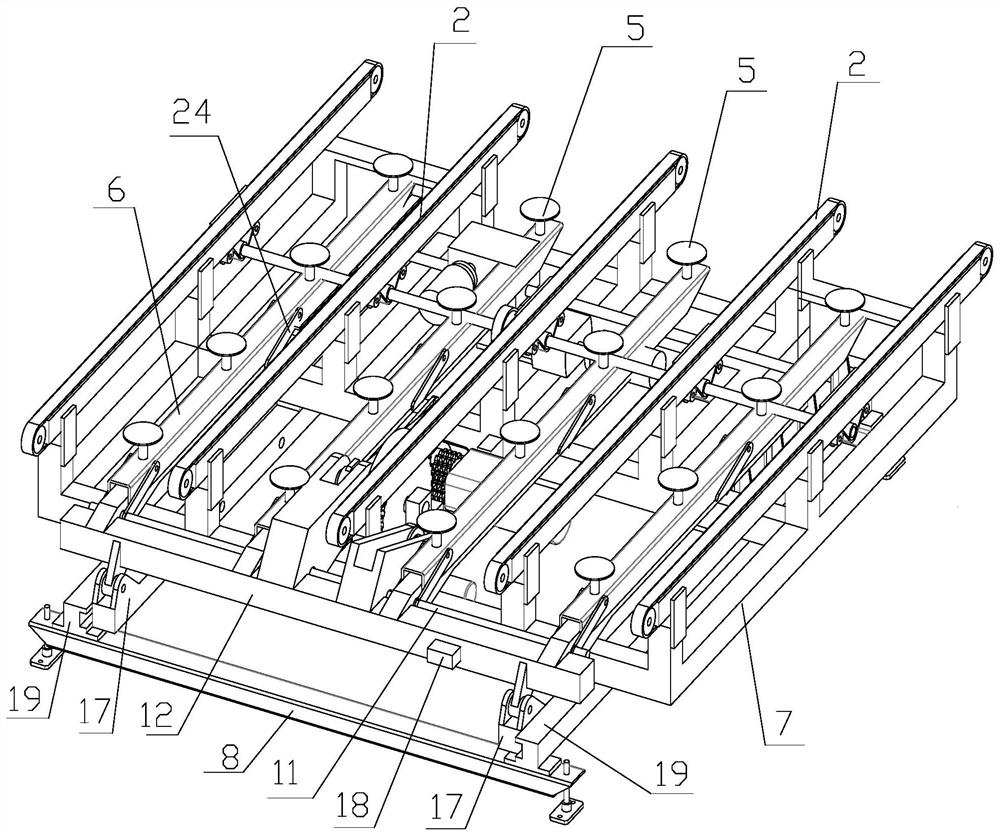

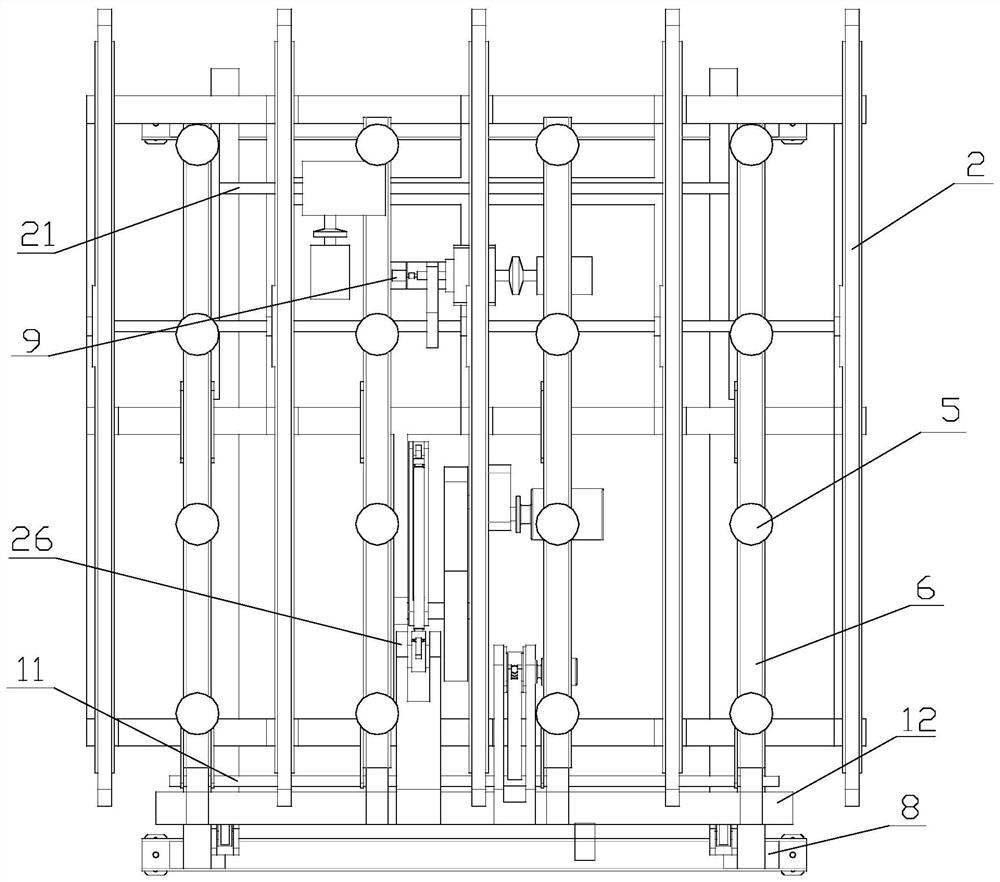

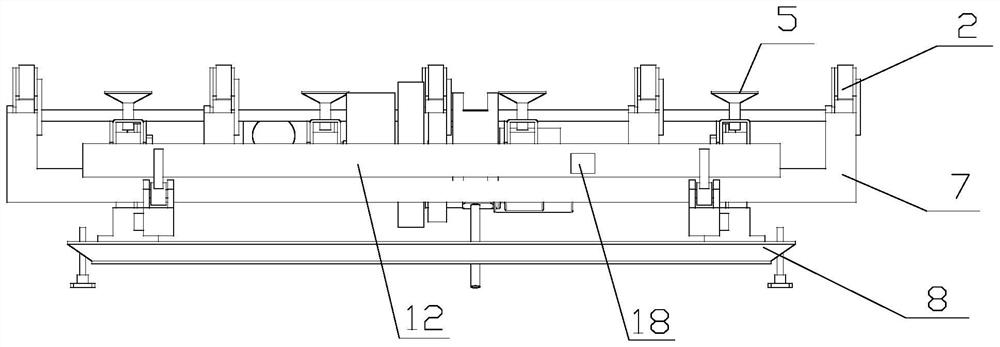

[0059] Such as Figure 1-8 As shown, the flat glass automatic stacking device includes a flat glass automatic parallel conveying line, a PLC controller (not shown), a frame support 7 and a frame support 8, and the automatic conveying production line is composed of a plurality of horizontally spaced parallel conveying belts 2 components, the conveyor belt 2 is fixed on the upper surface of the frame-shaped bracket 7, each conveyor belt 2 is connected in sections, and the frame-shaped bracket 7 of the rear section of the conveyor belt 2 (the rear section of the conveyor belt shown in the figure) is placed on the fixed frame The upper surface of the support 8 is characterized in that: a counting encoder 9 is fixed on the rotating shaft of the conveyor belt 2,

[0060] There is a support plate 6 for fixing the suction cup 5 in the interval of the rear section of the adjacent conveyor belt 2. There is a fixed plate 10 parallel to the support plate 6 below the support plate 6. Two c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com