Float glass packaging box

A float glass, packaging box technology, used in transportation and packaging, containers, containers to prevent mechanical damage, etc., can solve problems such as danger, high cost, and inability to recycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

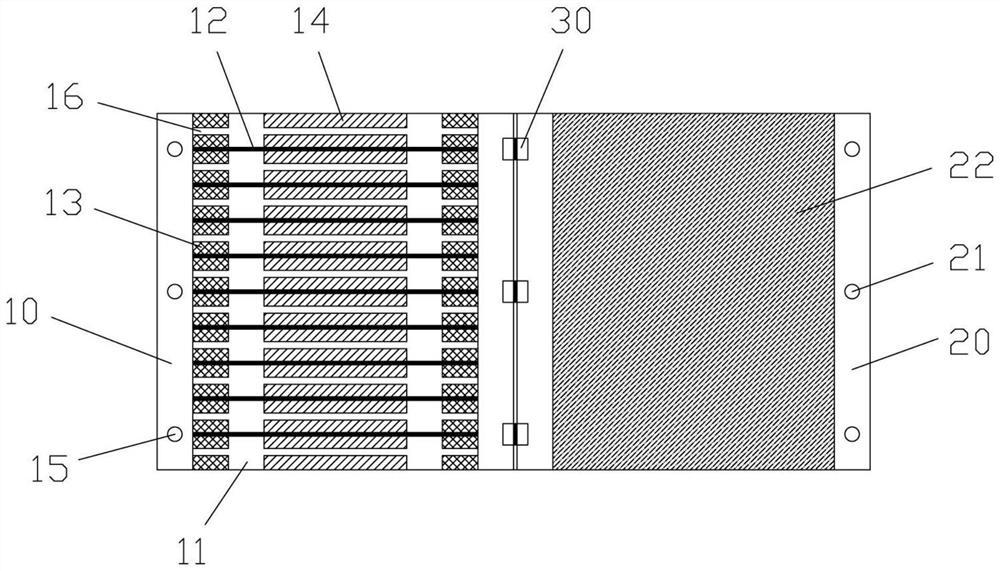

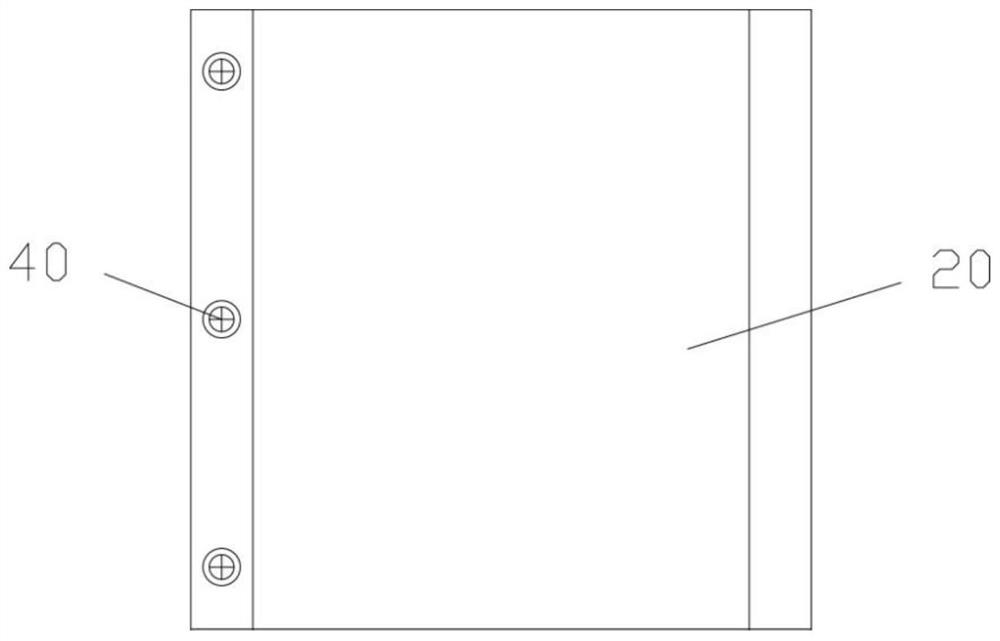

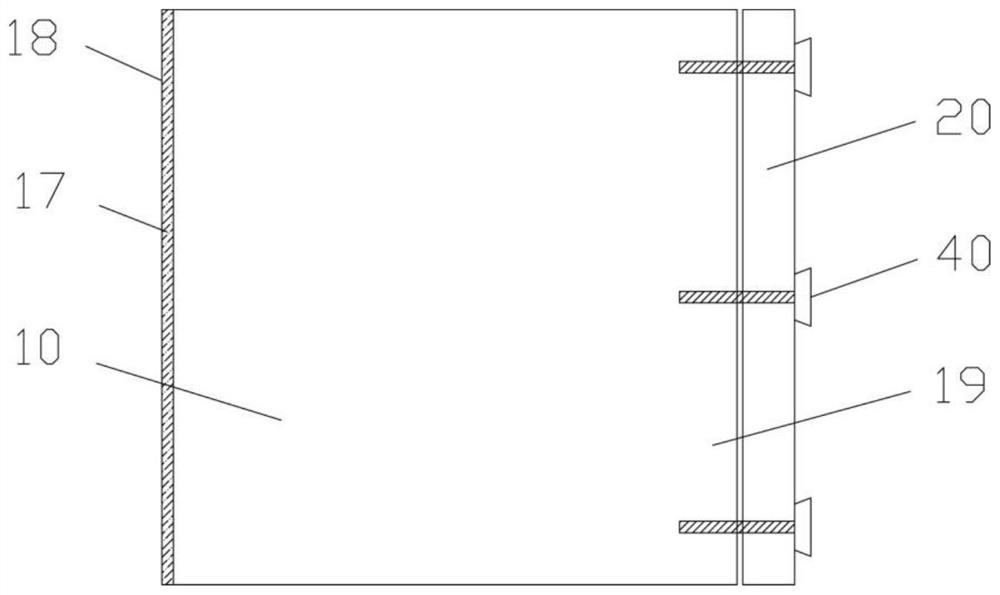

[0017] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0018] like Figure 1 to Figure 3 As shown, a float glass packaging box according to the present invention includes a correspondingly connected box body 10 and a door body 20, and a cavity 11 is formed inside the box body 11, and a plurality of partitions 12 are fixed at even intervals in the cavity body 11. The upper surface and the lower surface of the connection between the partition 12 and the inner wall of the cavity 11 are respectively provided with positioning blocks 13, and the positioning blocks 13 between two adjacent partitions 12 are formed to form a positioning guide groove for placing float glass 16 , the middle position of the partition 12 and the top wall and the bottom wall of the cavity 11 are respectively provided with anti-vibration components 14 . With such a structural setting, its working principle is as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com