A universal jig for machining flange fork bolt holes

A flanged fork bolt and flanged fork technology, which is used in manufacturing tools, metal processing equipment, metal processing machinery parts, etc. The problem of low clamping positioning accuracy can reduce the clamping time, improve the clamping and positioning efficiency, and improve the effect of chip removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

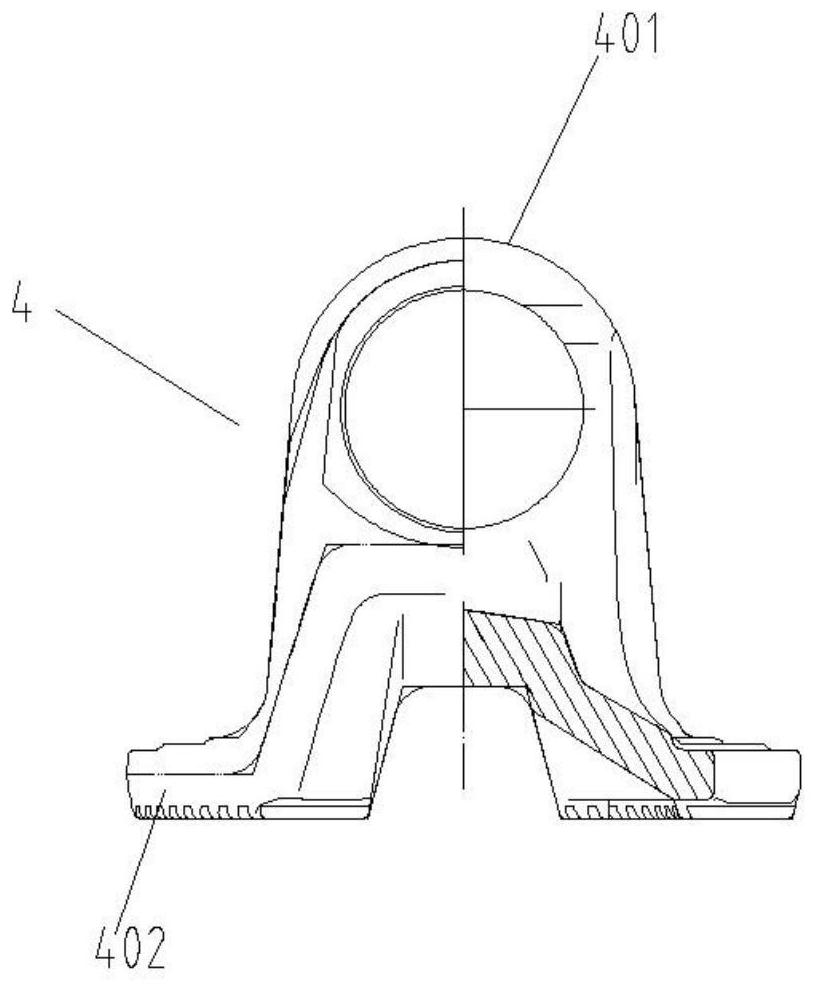

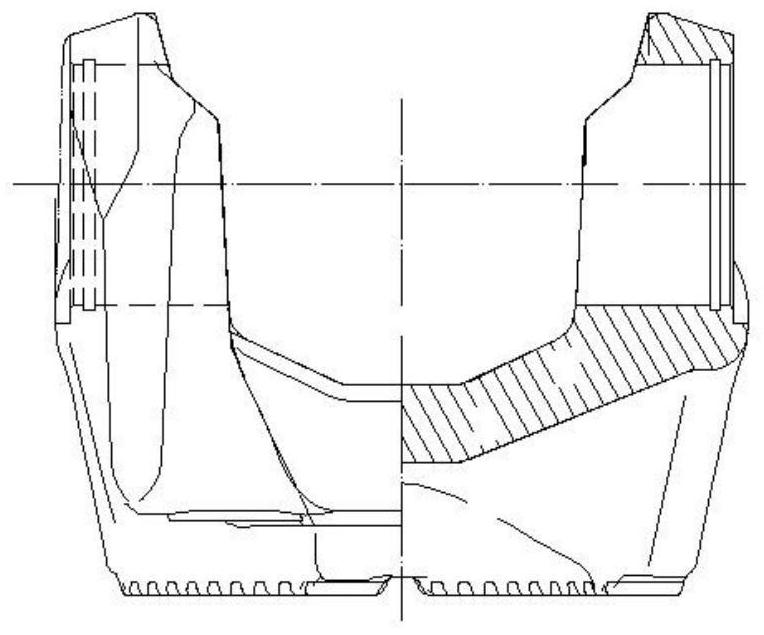

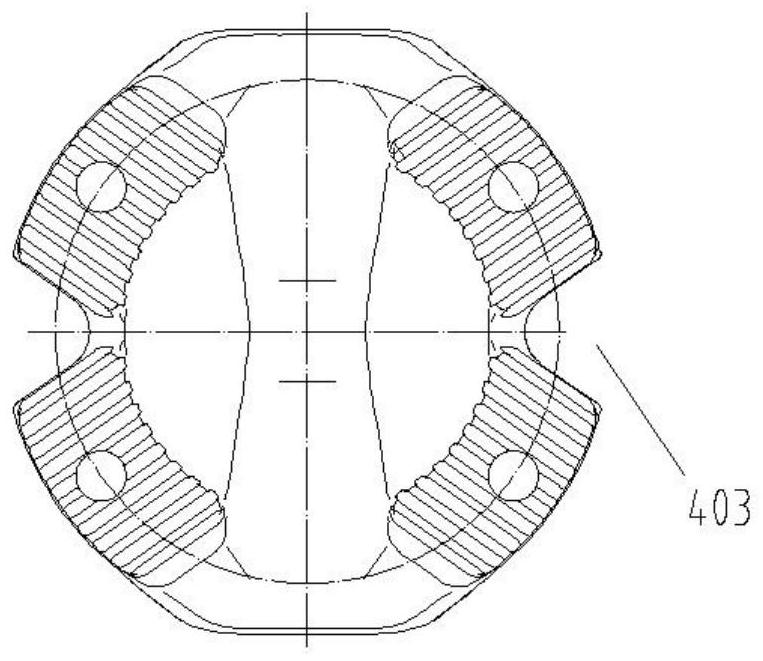

[0027] Such as Figure 3-4 As shown, the structure of this embodiment includes a base 1, a self-centering positioning mechanism, a first pressing mechanism and a second pressing mechanism. The self-centering positioning mechanism is arranged on the base 1 and includes two sets of oppositely arranged V Shaped positioning arms 6 are symmetrically distributed on the upper surface of the base 1, and each group of V-shaped positioning arms 6 can move toward or away from another group of V-shaped positioning arms 6, and the flange fork 4 is placed on two groups of V-shaped positioning arms 6. Between the V-shaped positioning arms 6, radial positioning is carried out by two groups of V-shaped positioning arms 6;

[0028] The first pressing mechanism 5 is arranged above the flange fork 4, and its lower surface is a V-shaped surface, which is used to cooperate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com