A 1t@2h-mos 2 /sns 2 Preparation method, product and application of visible light-responsive photocatalyst

A photocatalyst and visible light technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of poor conductivity, carrier separation and migration, etc., and achieve simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

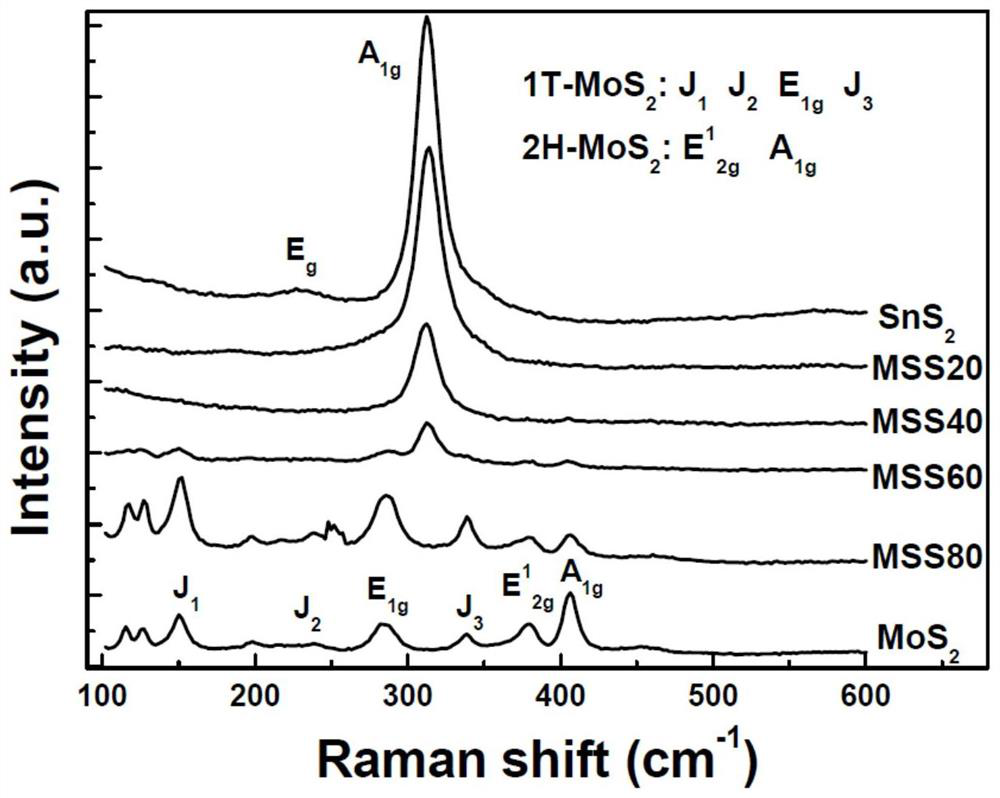

[0050] 1T@2H-MoS 2 / SnS 2 The preparation method of visible light responsive photocatalyst comprises the following steps:

[0051] (1) Mixing solution: Dissolve 0.151g of sodium molybdate hydrate and 0.763g of hydrated tin chloride in 80mL of deionized water, then add 2.174g of citric acid, 1.439g of thiourea, ultrasonically treat, and magnetically stir at room temperature for 1h Dissolved, the pH of the solution is 3-5;

[0052] (2) hydrothermal synthesis: the solution in step (1) was transferred to a 100mL reaction kettle, heated to 220°C, and cooled to room temperature naturally after being kept for 24h;

[0053] (3) Separation and washing: The reaction product in step (2) was collected, centrifuged, washed alternately with ethanol and distilled water to remove impurities, and then vacuum-dried at 60° C. for 8 hours to obtain MoS 2 The mass ratios of 1T@2H-MoS were 20% 2 / SnS 2 Photocatalyst, named MSS20.

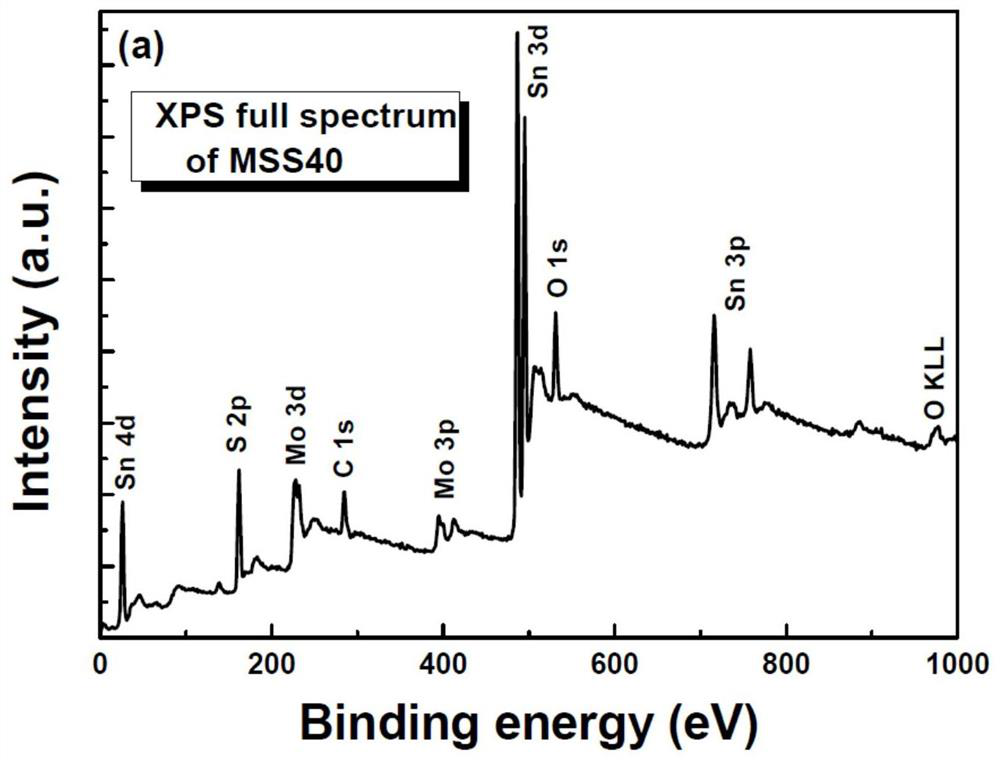

Embodiment 2

[0055] 1T@2H-MoS 2 / SnS 2 The preparation method of visible light responsive photocatalyst comprises the following steps:

[0056] (1) Mixing solution: Dissolve 0.303g sodium molybdate hydrate and 0.572g tin chloride hydrate in 80mL deionized water, then add 1.725g citric acid, 1.304g thiourea, ultrasonically treat, and magnetically stir at room temperature for 1h Dissolved, the pH of the solution is 3-5;

[0057] (2) hydrothermal synthesis: the solution in step (1) was transferred to a 100mL reaction kettle, heated to 220°C, and cooled to room temperature naturally after being kept for 24h;

[0058] (3) Separation and washing: The reaction product in step (2) was collected, centrifuged, washed alternately with ethanol and distilled water to remove impurities, and then vacuum-dried at 60° C. for 8 hours to obtain MoS 2 The mass ratios of 1T@2H-MoS were 40% 2 / SnS 2 Photocatalyst, named MSS40.

Embodiment 3

[0060] 1T@2H-MoS 2 / SnS 2 The preparation method of visible light responsive photocatalyst comprises the following steps:

[0061] (1) Mixing solution: Dissolve 0.454g sodium molybdate hydrate and 0.381g tin chloride hydrate in 80mL deionized water, then add 1.276g citric acid, 1.17g thiourea, ultrasonically treat, and magnetically stir at room temperature for 1h Dissolved, the pH of the solution is 3-5;

[0062] (2) hydrothermal synthesis: the solution in step (1) was transferred to a 100mL reaction kettle, heated to 220°C, and cooled to room temperature naturally after being kept for 24h;

[0063] (3) Separation and washing: The reaction product in step (2) was collected, centrifuged, washed alternately with ethanol and distilled water to remove impurities, and then vacuum-dried at 60° C. for 8 hours to obtain MoS 2 The mass ratios of 1T@2H-MoS were 60% 2 / SnS 2 Photocatalyst, named MSS60.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com