Belt weigher calibration device

A technology of a calibration device and a belt scale, applied in the field of mechanical structure, can solve the problems that the belt scale cannot achieve physical calibration, the size of the simulation calibration error is difficult, the data and the theoretical value are very different, etc., and the overall structure design is compact and ingenious, and speed tracking is achieved. Accurate and easy to promote the application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

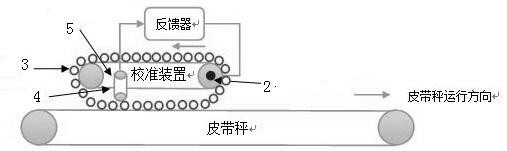

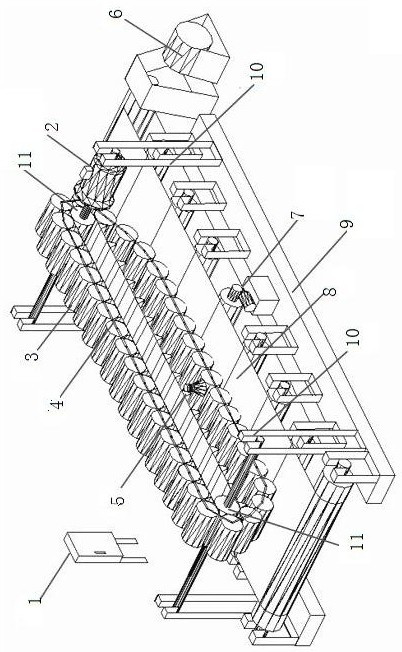

[0019] Embodiment 1: see figure 1 , a kind of belt scale calibration device, said calibration device includes instrument box 1, speed-regulating motor 2, chain code 3, chain code drive chain 4 and high-speed camera 5, calibration device supporting frame 10, said chain code 3 and high-speed camera 5 is fixed on the chain code driving chain 4, and the calibration device is arranged on the calibration device support frame. The calibration device is set on the belt scale, and the calibration device and the belt scale are installed on the conveyor belt conveyor support. The head and tail of the calibration device are respectively provided with rollers 11, and the roller shafts of the head are in line with the adjustment The shaft of the high-speed motor is connected, and the number of the high-speed cameras is 2-4, which are evenly arranged on the chain 4 driven by the chain code. Chain sign indicating number drives chain 4 and adopts rubber bearing, and the surface is the concave...

Embodiment 2

[0022] Embodiment 2: the calibration method of the belt scale calibration device, the method is as follows: the chain code is sleeved on a section of cyclically revolving drive chain, the drive chain is driven by a speed-regulating electric drive, the high-speed camera is installed on the drive chain, and the high-speed camera collects The information is transmitted to the feedback device, and the feedback device outputs the control current to the speed-regulating motor. Such as figure 2 , the lower half circle of the driving chain is in the same direction as the running direction of the belt scale belt. The camera installed on the driving chain can only play a tracking role when the driving chain turns to the lower half circle. Therefore, in order to improve the tracking effect, it is recommended to evenly Arrange 2 to 3 cameras in an orderly manner. The cameras work in rotation to ensure that the calibration device can track the belt speed at all times. After the belt sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com