Bidirectional balance double-acting buffer device for hydraulic cylinder piston

A buffer device and double-acting technology, applied in the hydraulic field, can solve the problems of increasing the weight of the oil cylinder, increasing the number of parts, and the complex structure of the buffer technology, so as to ensure reliability and stability, easy processing and assembly, and ease the cumbersome assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]The present invention will be further described below based on the drawings and embodiments.

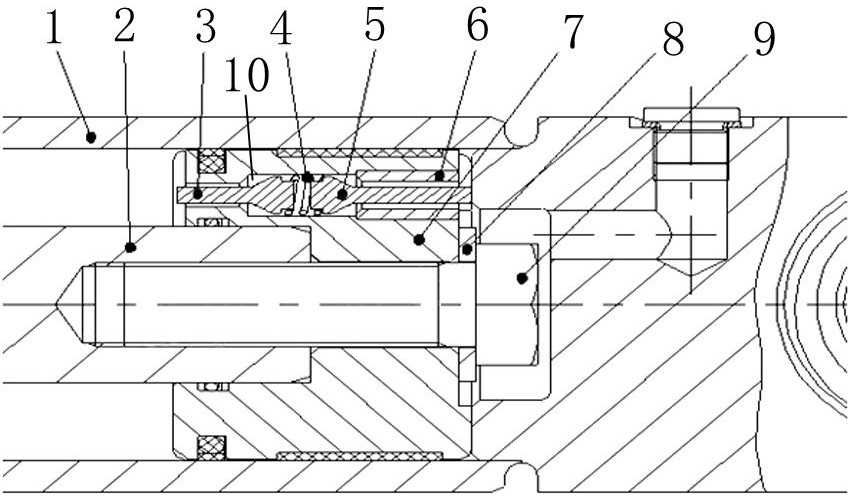

[0015]Such asfigure 1As shown, a hydraulic cylinder piston two-way balanced double-acting buffer device, a piston 7 is placed in the cylinder tube 1 of the hydraulic cylinder, and the piston rod 2 is fixed to the piston 7 through a bolt 9 and a washer 8. The piston 7 is provided with a through valve groove 10 along the axial direction, and the valve groove 10 is used to communicate the large cavity and the small cavity of the hydraulic cylinder. A valve core I3 and a valve core II5 are arranged in the valve groove 10, and both the valve core I3 and the valve core II5 include an oil blocking part (the oil blocking part is used to control the oil passage of the valve groove 10 to connect the large cavity and the small cavity of the hydraulic cylinder The oil blocking part of spool Ⅰ3 and the oil blocking part of spool Ⅱ5 are both located inside the valve groove 10, and the oil blocking pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com