Drum washing machine and control method thereof

A front-loading washing machine and inner tub technology, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of little practical significance, waste of water storage in the inner tub and the outer tub, accumulation of dirt in the inner tub and the outer tub, etc. , to avoid dirt adhesion, save water resources, improve user health and user experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

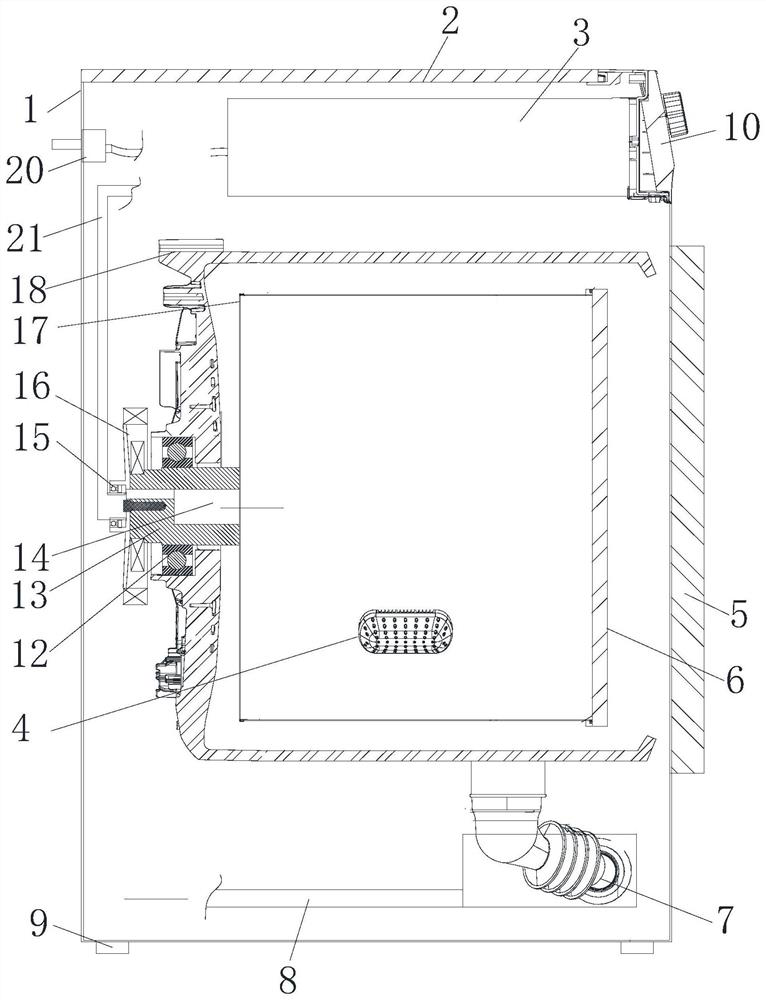

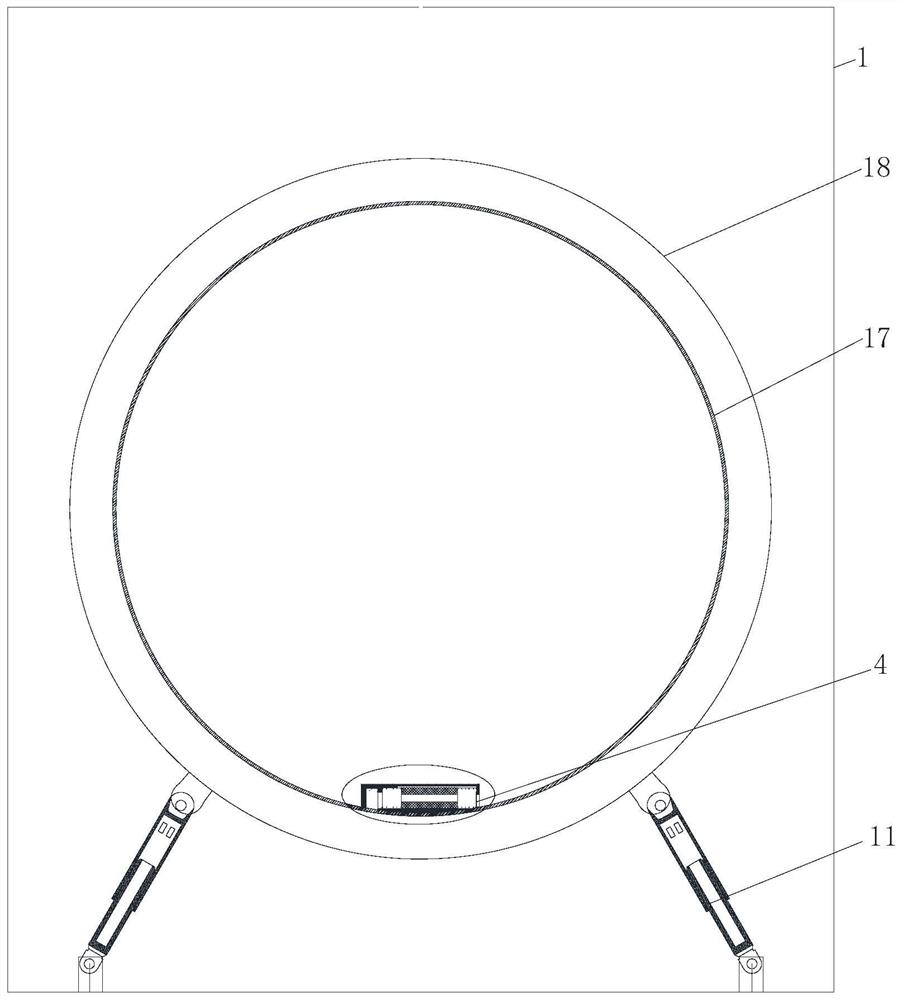

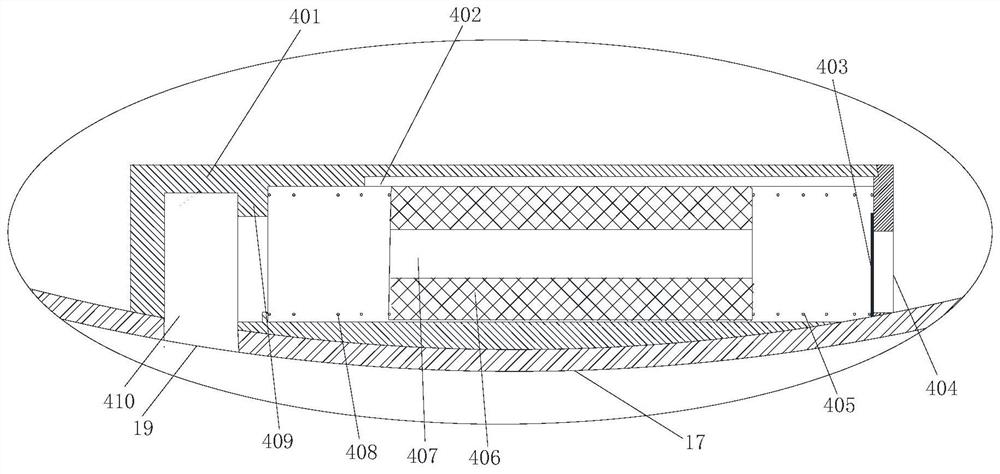

[0031] A drum washing machine of the present invention and its control method are described in detail below in conjunction with the accompanying drawings:

[0032] Such as Figure 1-Figure 5 As shown, this embodiment provides a drum washing machine with a structural design of a non-porous inner cylinder. When washing, the inner cylinder independently holds washing water, and there is no water between the inner cylinder and the outer cylinder, thereby avoiding the dirt between the inner cylinder and the outer cylinder. The possibility of attachment greatly improves user health and user experience, and greatly saves water resources.

[0033] The drum washing machine of this embodiment has a casing 1, and the casing 1 includes: a top panel 2, a front panel, a back panel and a bottom panel. Footings 9 are installed and fixed on the bottom plate for supporting the whole washing machine. The housing 1 has an outer cylinder 18 inside, and an inner cylinder 17 is arranged coaxially ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com