A Composite Brake Control System

A control system and composite braking technology, applied in the direction of braking control system, braking safety system, electric braking system, etc., can solve the problem that the ABS braking system and the regenerative braking system cannot work in harmony

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

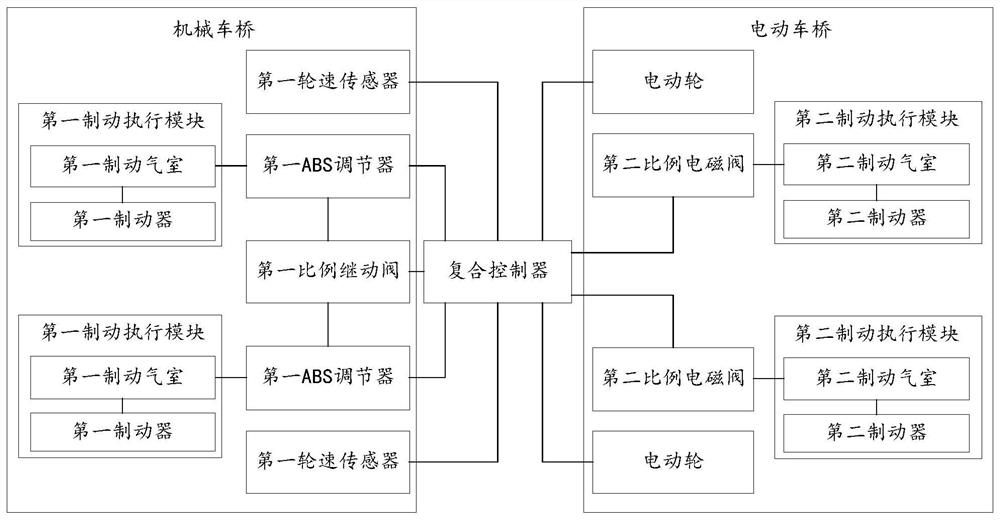

[0038] Before the application is explained, the relevant technologies are described as follows:

[0039] In a traditional car, the torque generated by the engine must pass through mechanical devices such as gears and transmission shafts to drive the wheels forward. During this process, part of the energy will be consumed by mechanical motion. Among them, the axles that drive the wheels forward through mechanical devices such as gears and transmission shafts are called mechanical axles.

[0040] The electric vehicle equipped with a motor (the axle driven by the motor to move the wheels is called an electric axle), compared with the traditional car, simplifies the mechanical transmission mechanism, and the electric energy generated by the battery is directly transmitted to the motor arranged in the wheel. The energy loss in the mechanical transmission process is greatly reduced, and the efficiency of the motor drive is greatly improved. Not only that, electric wheel vehicles ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com