Auxiliary handle and electric tool

A technology of auxiliary handles and handles, which is applied in the field of auxiliary handles, can solve problems such as loose and complex structures, and achieve the effects of low manufacturing cost, simple structure, and high-efficiency adjustment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

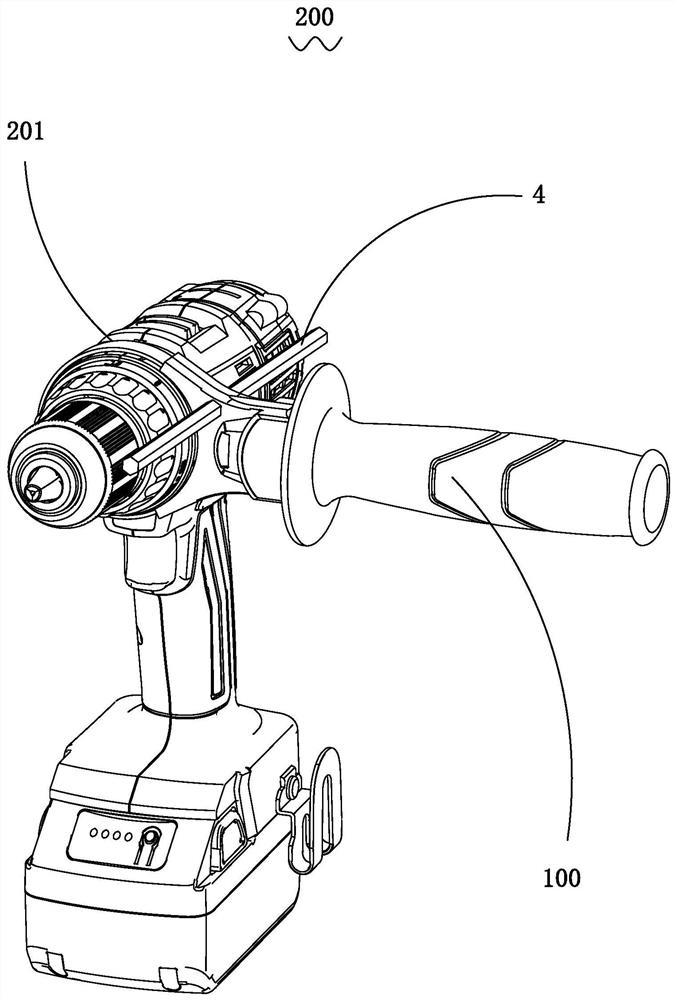

[0024] Such as Figure 1 to Figure 5 Shown is an auxiliary handle 100 related to a preferred embodiment of the present invention, which is applied to a power tool 200 such as a hammer drill. The electric tool 200 includes a tool body 201 with a working axis, the auxiliary handle 100 is fixedly connected to the front of the tool body 201 , and the auxiliary handle 100 is arranged along a direction perpendicular to the working axis.

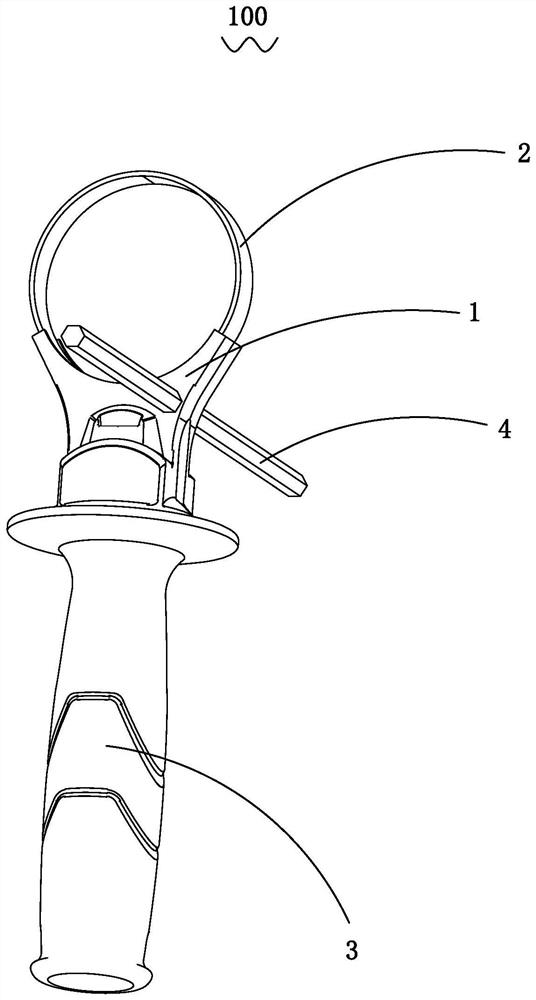

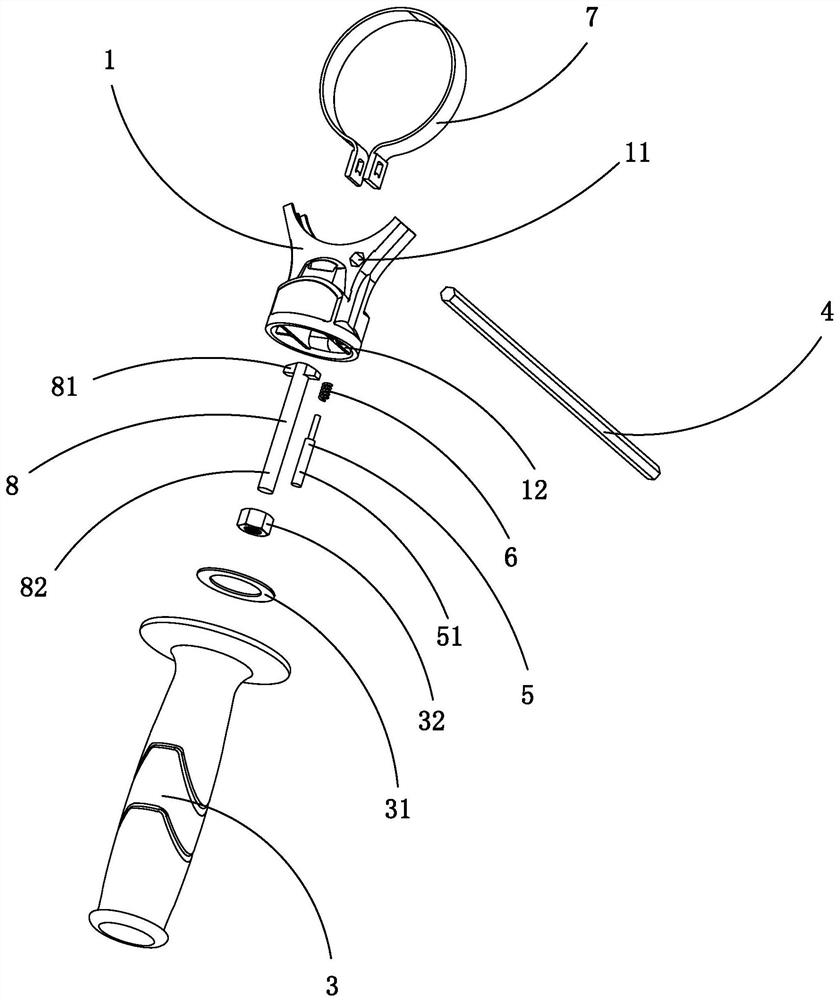

[0025] Such as figure 2 and 3 As shown, the auxiliary handle 100 includes a base body 1 , a clamp assembly 2 supported on the base body 1 , and a handle body 3 disposed at the bottom of the base body 1 , and the clamp assembly 2 is connected to the handle body 3 . The clamp assembly 2 includes a clamp 7 supported on the upper end of the seat body 1 and a fixing member 8 accommodated in the seat body 1, the upper end of the fixing member 8 is clamped on the lower end of the clamp 7, and the fixing member The lower end of 8 is fixed in the handle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com