Stainless steel section bar cutting device

A cutting device, stainless steel technology, applied in the direction of feeding device, positioning device, large fixed members, etc., can solve the problems of stainless steel profiles such as easy wear, inconvenient processing, concave corners, etc., to achieve the effect of improving safety and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

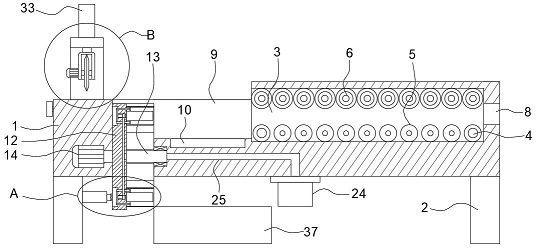

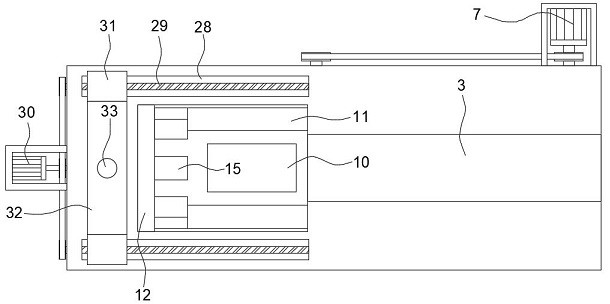

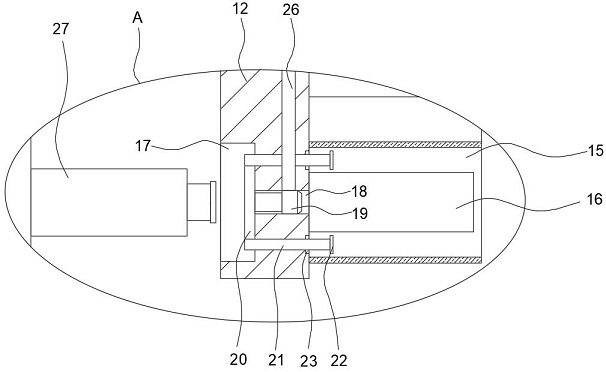

[0027] refer to Figure 1-5 , a stainless steel profile cutting device, comprising a processing table 1 and two support seats 2 fixedly installed on both sides of the lower end of the processing table 1, a conveying box 3 is embedded on the right side of the upper end of the processing table 1, and a conveying box 3 is provided inside the conveying box 3. device, the conveying device includes driving rollers 4 that are connected to the front and rear inner walls of the conveying box 3 and are respectively located at both ends of the lower interior of the conveying box 3, and play the role of conveying stainless steel profiles. There are a plurality of guide rollers 5, the guide rollers 5 are flush with the upper ends of the driving rollers 4, and play the role of supporting the stainless steel profile. The ends of the two driving rollers 4 on the rear side both penetrate the rear side wall of the conveying box 3 and extend to the processing table 1 At the rear, a first motor 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com