Chemical soil treatment device

A soil and chemical technology, applied in the restoration of polluted soil, incinerators, grain treatment, etc., can solve problems such as equipment failure, neglect of soil debris treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

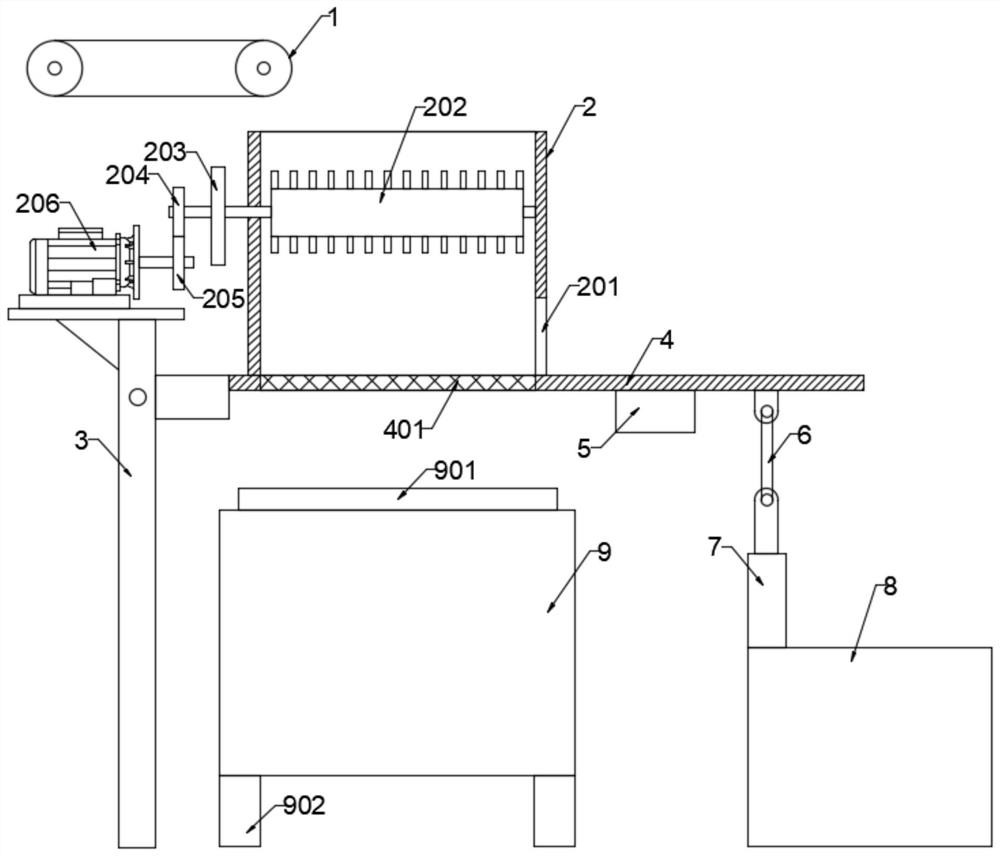

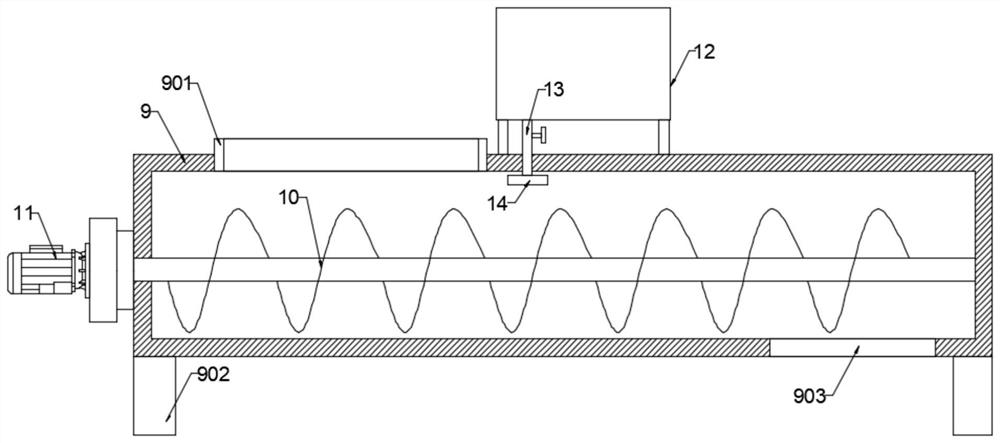

[0028] see Figure 1-5 , a chemical soil treatment device, comprising a feed mechanism 1, a support frame 3, a movable plate 4 installed on the support frame 3 and a sundry disposal box 8, the movable plate 4 is fixedly connected with a pretreatment box 2, the movable plate 4. The plate body located at the bottom of the cavity of the pretreatment box 2 is set as a first grid plate 401, and a soil remediation box 9 for repairing soil is arranged below the first grid plate 401. One end of the movable plate 4 is connected to the supporting frame 3 Rotationally connected, the other end of the movable plate 4 is hinged with a symmetrically distributed connecting rod 6, and the connecting rod 6 is hinged with the piston rod of the cylinder 7 installed on the sundry disposal box 8. mechanism, the movable plate 4 is fixedly connected with a vibrating motor 5 for vibrating the movable plate 4, and the side of the same direction of the pretreatment box 2 and the sundries disposal box 8 ...

Embodiment 2

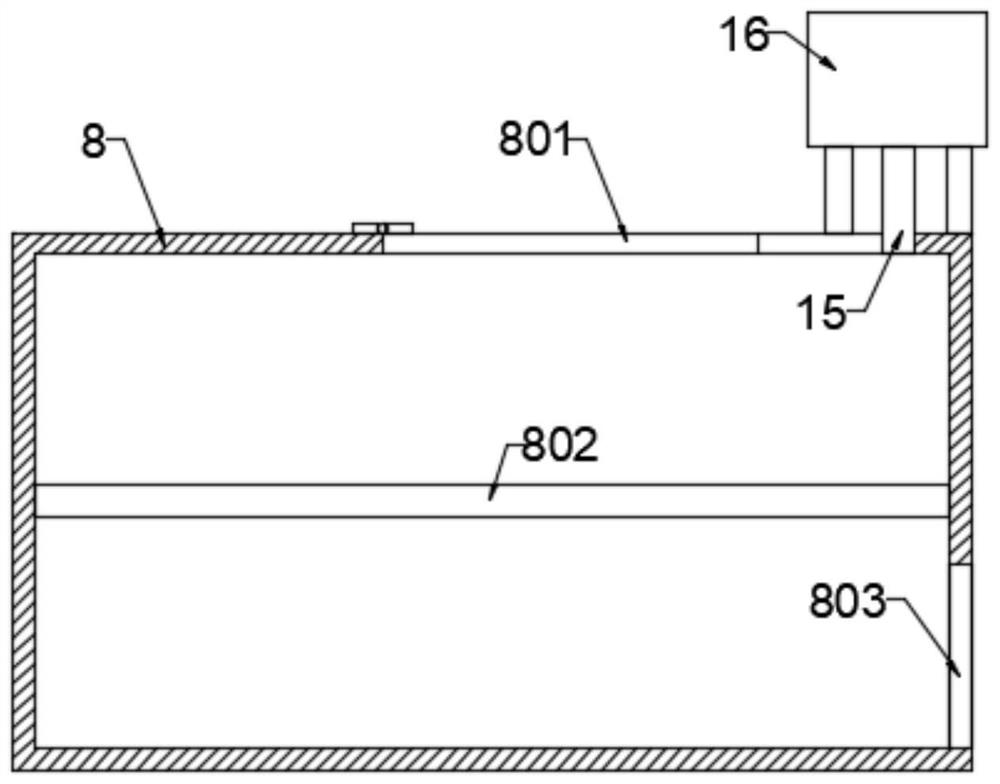

[0033] This embodiment is expanded on the basis of Embodiment 1. The inner cavity of the flue gas treatment box 16 is fixedly connected with a partition plate 1601 that divides it into a first cavity 1602 and a second cavity 1603. The second cavity 1603 communicates with the smoke exhaust pipe 15. The flue gas treatment box 16 is provided with a flue gas treatment mechanism 17. The flue gas treatment mechanism 17 includes an activated carbon filter plate 1701, a cathode plate 1702 and an anode plate 1703. The activated carbon filter The plate 1701 is nested in the second cavity 1603 and is fixedly connected with the second handle 20 located outside the flue gas treatment box 16. There is an open box 1705 nested in the second cavity 1603 under the activated carbon filter plate 1701, and the opening The opening of the box 1705 faces the activated carbon filter plate 1701. One side of the opening box 1705 is fixedly connected with the third handle 21 located outside the flue gas t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com