Coffee high-temperature processing pre-fermentation device

A high-temperature processing and pre-fermentation technology, applied in green coffee processing, etc., can solve problems such as inability to discharge carbon dioxide, inability to monitor coffee beans, inability to automatically adjust temperature and humidity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

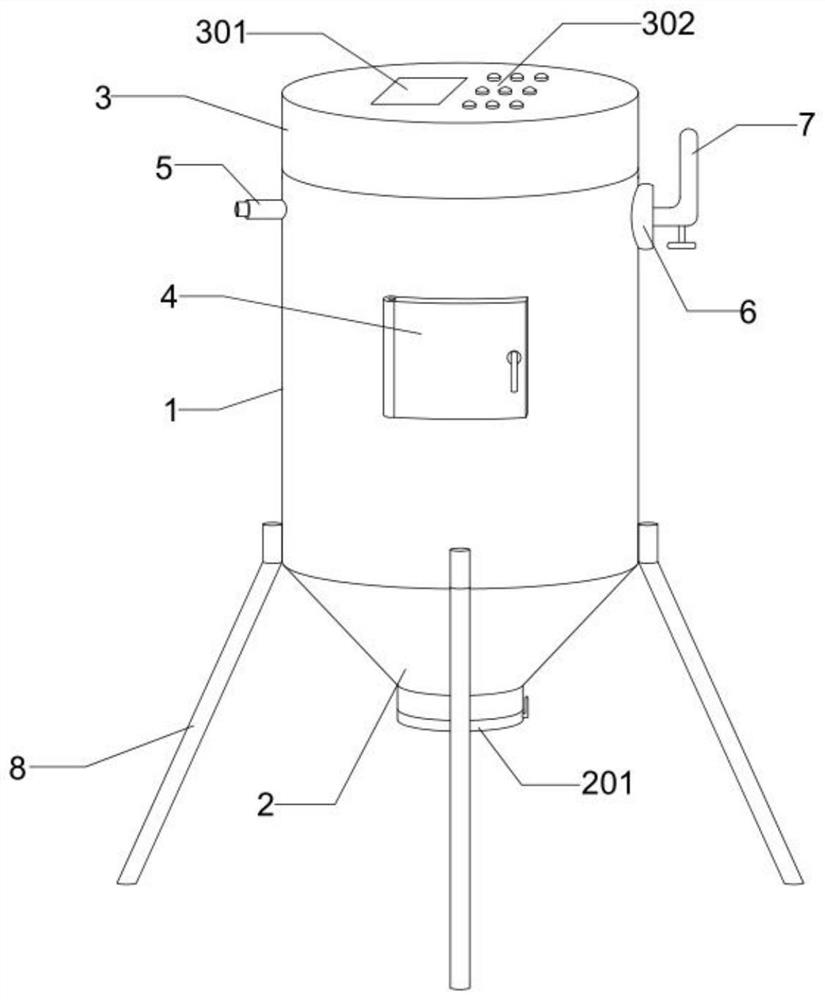

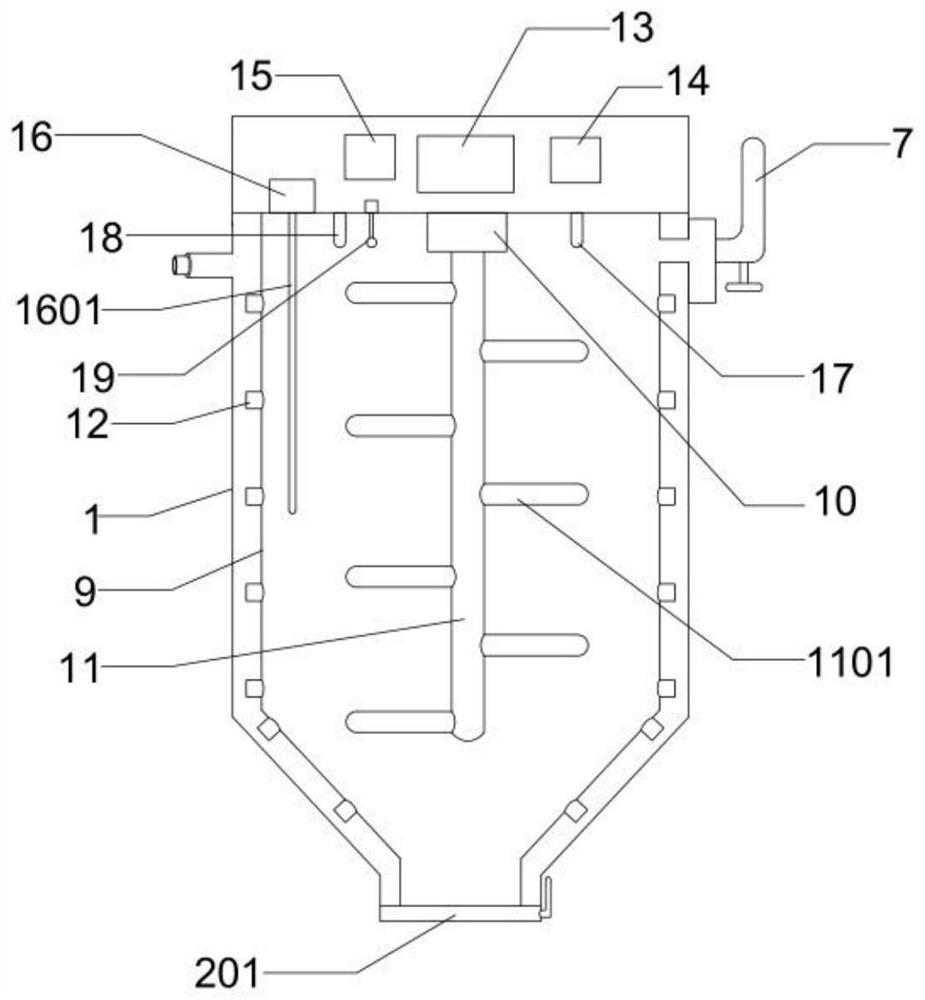

[0027] A coffee high-temperature processing pre-fermentation device is characterized in that it includes: outer barrel wall 1, material outlet 2, control part 3, material feeding port sealing door 4, water inlet 5, exhaust fan 6, exhaust pipe 7, bracket 8, Inner barrel wall 9, motor 10, stirring rod 11, sprinkler head 12, microprocessor chip 13, microcomputer timer 14, memory 15, PH measuring instrument 16, temperature sensor 17, humidity sensor 18, carbon dioxide measuring instrument 19;

[0028] The lower part of the outer barrel wall 1 is connected to the discharge port 2, and the upper part is connected to the control part 3; there is a feed port on the side wall of the outer barrel wall 1, and a sealing door 4 is connected to the feed port; the outer barrel wall 1 is close to the upper side The water inlet 5 is connected on the wall, and the exhaust fan 6 is connected to the outer barrel wall 1 on the opposite side of the water inlet 5, and the exhaust fan 6 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com