Self-resetting friction energy dissipation steel frame joint based on shape memory alloy

A technology of memory alloy and frictional energy consumption, which is applied in building components, building structures, and earthquake resistance, can solve the problems of difficult post-earthquake repairs and threats to structural safety, and achieves good application prospects, convenient use, and solutions to residual deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

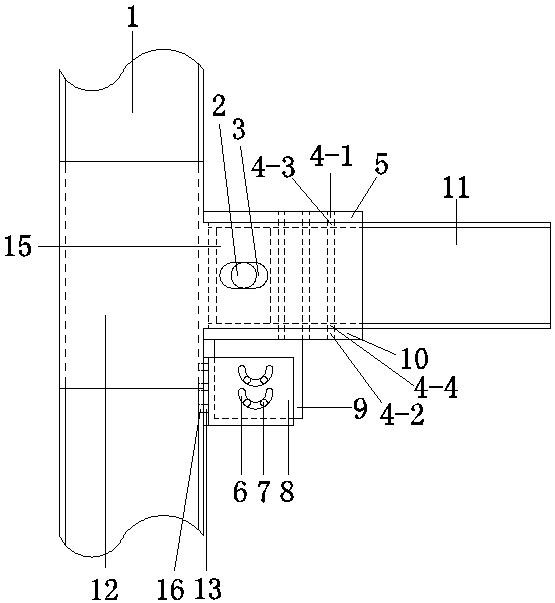

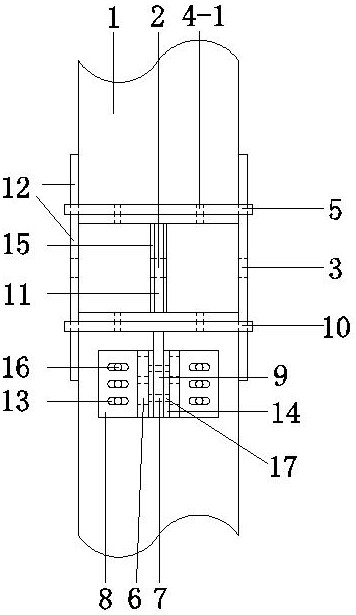

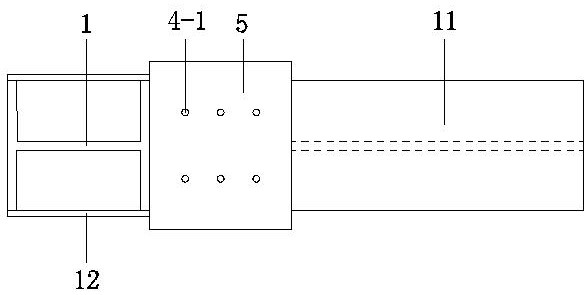

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments thereof.

[0046] A self-resetting friction energy-dissipating steel frame node based on shape memory alloys, including H-shaped steel columns 1, upper cover plates 5, lower cover plates 10, H-shaped steel beams 11, steel sleeve plates 12, shape memory alloy ribs 18, friction Energy dissipation system; there is a gap between the H-shaped steel column 1 and the H-shaped steel beam 11; both sides of the beam-column node area formed by the H-shaped steel column 1 and the H-shaped steel beam 11 are welded with steel sleeve plates 12, and the steel sleeve plates 12 The middle part of the side near the H-shaped steel column 1 is provided with a steel sleeve plate hole 3, and the steel sleeve plate hole 3 is elliptical; the middle part of the H-shaped steel beam web on the side of the H-shaped steel beam 11 close to the H-shaped steel column 1 Be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com