Forming Technology of Bubble Hollow Glass Sphere for Architectural Decoration

A technology of hollow glass and molding process, which is applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., and can solve problems such as the inability to prepare hollow bubble glass balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

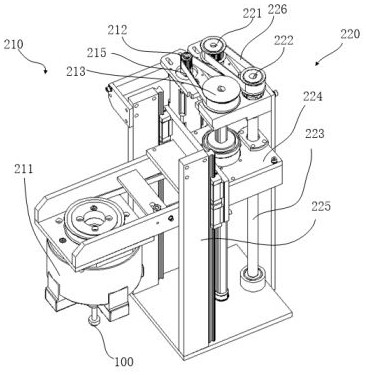

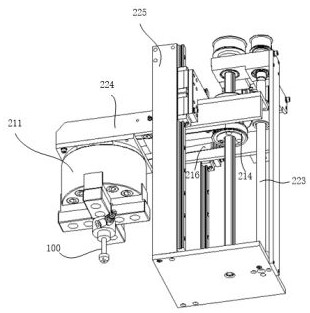

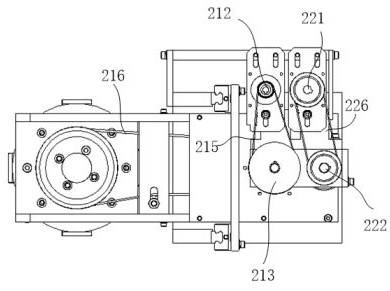

[0059] This embodiment provides a kind of opening-type architectural decoration glass forming equipment, please refer to Figure 1 to Figure 7 ,include:

[0060] Blowing head 100, lifting and rotating mechanism 200 and preliminary shaping manipulator 300;

[0061] The blowing head 100 is installed on the lifting and rotating mechanism 200, and can be rotated and lifted under the drive of the lifting and rotating mechanism 200;

[0062]The blowing head 100 has a first gas outlet state and a second gas outlet state; when the blowing head 100 was in the first gas outlet state, the blowing head 100 interrupted the gas outlet to form small glass bubbles in the molten glass mass; When 100 is in the second gas outlet state, the blowing head 100 continuously vents to form a cavity in the molten glass gob;

[0063] The preliminary shaping manipulator 300 is provided with a scraping head 310, which is configured to be close to or away from the molten glass mass, and capable of scrapin...

Embodiment 2

[0100] This embodiment provides a kind of closed type building decoration glass forming equipment, please refer to Figure 1 to Figure 10 ,include:

[0101] Blowing head 100, lifting and rotating mechanism 200, primary shaping manipulator 300 and secondary shaping manipulator 400;

[0102] The blowing head 100 is installed on the lifting and rotating mechanism 200, and can be rotated and lifted under the drive of the lifting and rotating mechanism 200;

[0103] The blowing head 100 is provided with at least one air outlet;

[0104] The blowing head 100 has a first gas outlet state and a second gas outlet state; when the blowing head 100 was in the first gas outlet state, the blowing head 100 interrupted the gas outlet to form small glass bubbles in the molten glass mass; When 100 is in the second gas outlet state, the blowing head 100 continuously vents to form a cavity in the molten glass gob;

[0105] The preliminary shaping manipulator 300 is provided with a scraping hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com