Wood board stamping and punching equipment for building materials

A kind of punching equipment and wood board technology, which is applied in wood processing equipment, fixed drilling machines, bark area/debris/dust/waste removal, etc., can solve the problems that the accuracy of wood strip punching cannot be guaranteed and the safety of workers, etc. To achieve the effect of optimizing the punching effect, standardizing the punching position, and preventing obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

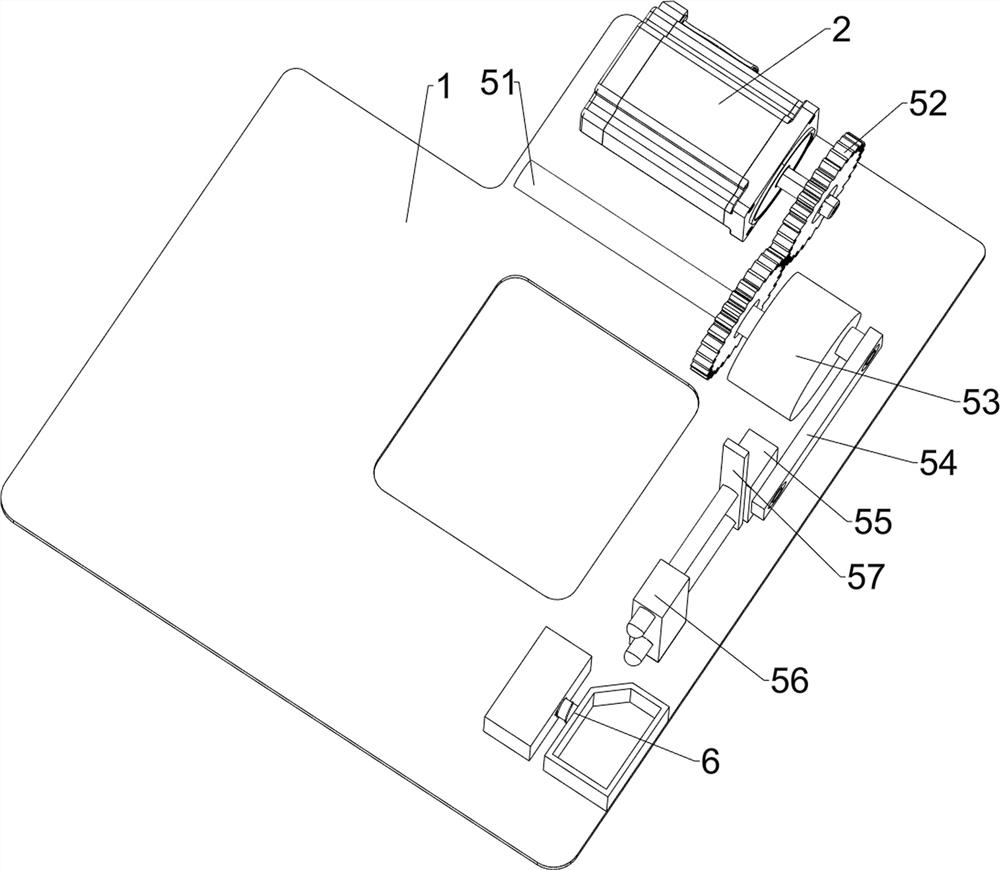

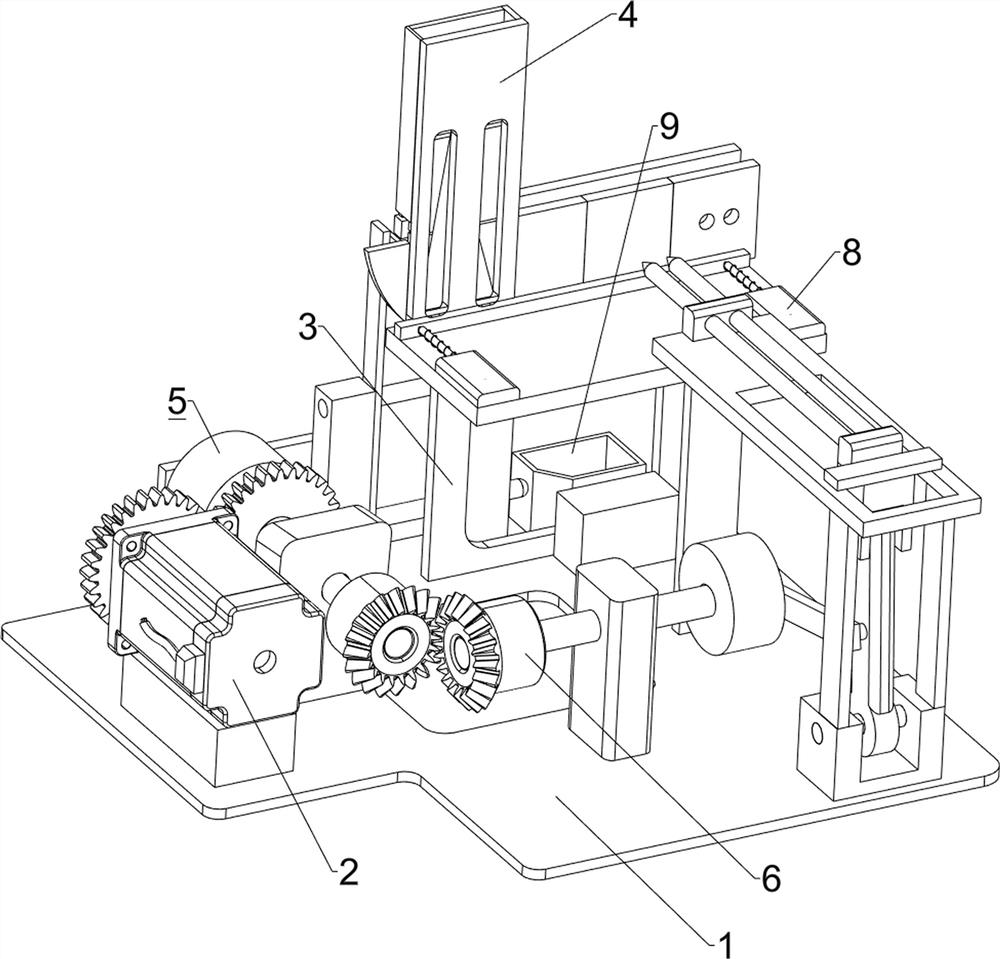

[0022] A kind of equipment for stamping and punching wood boards for building materials, such as figure 1 with figure 2 As shown, it includes a bottom plate 1, a servo motor 2, a mounting plate 3, a blanking box 4, a pushing mechanism 5 and a punching mechanism 6, a servo motor 2 is installed on the right side of the bottom plate 1, and a mounting plate is installed on the left side of the bottom plate 1. Plate 3, the upper right side of the mounting plate 3 is provided with a blanking box 4, the upper front side of the bottom plate 1 is provided with a pushing mechanism 5, and the upper rear side of the mounting plate 3 is provided with a punching mechanism 6.

[0023] When people want to punch holes in the planks, they usually need to manually punch holes in the planks, which cannot automatically punch holes in the planks. Therefore, people can use this device to first place the planks that need to be punched in the blanking box 4, Turn on the servo motor 2, the rotation o...

Embodiment 2

[0025] On the basis of Example 1, such as image 3 , Figure 4 with Figure 5 As shown, the pushing mechanism 5 includes a first rotating shaft 51, a spur gear 52, a first disk 53, a first rotating rod 54, a first push plate 55, a fixed block 56, a second push plate 57 and a sector baffle 58 , the bottom plate 1 is provided with a first rotating shaft 51 in a rotating manner on the right side, and a spur gear 52 is arranged on the front side of the first rotating shaft 51 and the output shaft of the servo motor 2, and the two spur gears 52 mesh, and the front end of the first rotating shaft 51 is provided with The first disc 53, the front side of the first disc 53 is rotatably provided with the first rotating rod 54, the left side of the bottom plate 1 is provided with a fixed block 56, and the sliding type in the fixed block 56 is provided with the first push plate 55, the first The push plate 55 is rotatably connected to the first rotating rod 54 , the second push plate 57...

Embodiment 3

[0030] On the basis of Example 2, such as figure 1 with figure 2 As shown, it also includes an adjusting bolt 7 and an elastic member 8. The front side of the mounting plate 3 is symmetrically provided with an adjusting bolt 7, and the rear side of the mounting plate 3 is provided with an elastic member 8 in a left-right and symmetrical sliding type. Elastic chute 9.

[0031] When punching holes, the wooden board may be unstable. At this time, the adjustment bolt 7 and the elastic member 8 can be adjusted to make the wooden board difficult to loosen and more stable when punching holes, so as to optimize the punching effect. When the pushing mechanism 5 When the left pushes the wooden block, the leftward movement of the first push plate 55 will drive the elastic chute 9 to move forward. During the hole, the sawdust that has punched will fall among the elastic chute 9, save the work that the workman cleans up after punching, and prevent the sawdust from hindering the work of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com