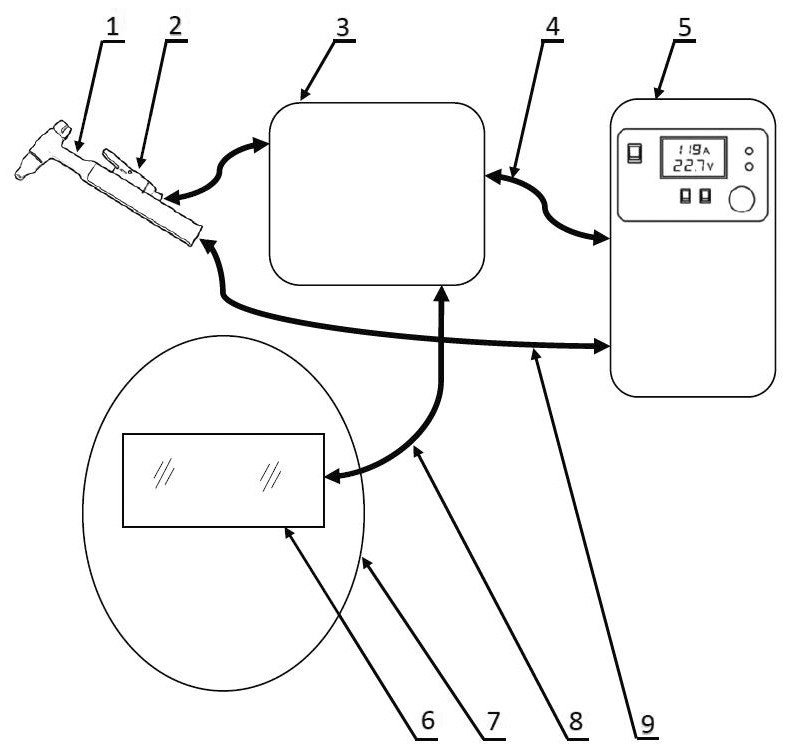

Welding equipment with semi-automatic auto-darkening welding helmet

A welding mask and welding equipment technology, applied in welding equipment, arc welding equipment, welding accessories, etc., can solve the problems of low cost, insufficient reliability, slow response, etc., and achieve cost reduction, reliable power supply, and improved reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0022] Example 1 Welding equipment with semi-automatic darkening welding helmet suitable for argon arc welding machine

[0023] The argon arc welding machine has a manual micro switch on the welding torch, which directly controls the work of the welding machine. Therefore, the dimming controller of the semi-automatic dimming welding mask is relatively simple, as long as it can provide a delay and obtain a small DC drive from the welding machine. The optical shutter can work normally. Dimming controller can adopt analog circuit, or digital circuit.

[0024] If digital circuits are used to design the dimming controller circuit board, the advantage is that the aforementioned delay time and the voltage output to the dimming shutter are easy to adjust. The disadvantage is that the circuit board design will be slightly complicated, and the current consumed by electronic components such as MCU is higher than that of analog The circuit needs to be large, and the cycle of software and...

example 2

[0026] Example 2 Welding equipment suitable for ordinary electric welding with semi-automatic darkening welding helmet

[0027] The controlled electric welding machine used in this technology must be able to control the work of the controlled electric welding machine, while ordinary electric welding machines do not have manual micro switches like argon arc welding machines, and different types and manufacturers of products have different working circuits , It is usually necessary to design the control circuit according to the specific situation, so that the welding machine becomes the controlled electric welding machine required by this technology. Generally speaking, compared with the semi-automatic dimming welding mask system of the argon arc welding machine in the previous example 1, the power conversion part and the start-stop control part of the electric welding machine should be added. Because this part of the circuit design does not belong to the technical innovation po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com