Novel high-pressure prefabricated cabin bus bridge and wiring method thereof

A technology of prefabricated cabins and busbar bridges, applied in the directions of busbar/circuit layout, electrical components, substation/switch layout details, etc., can solve the problem of increasing the cost of prefabricated cabin frames, failing to meet the height limit requirements of road transportation, and failing to complete small busbars on top of cabinets Maintenance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

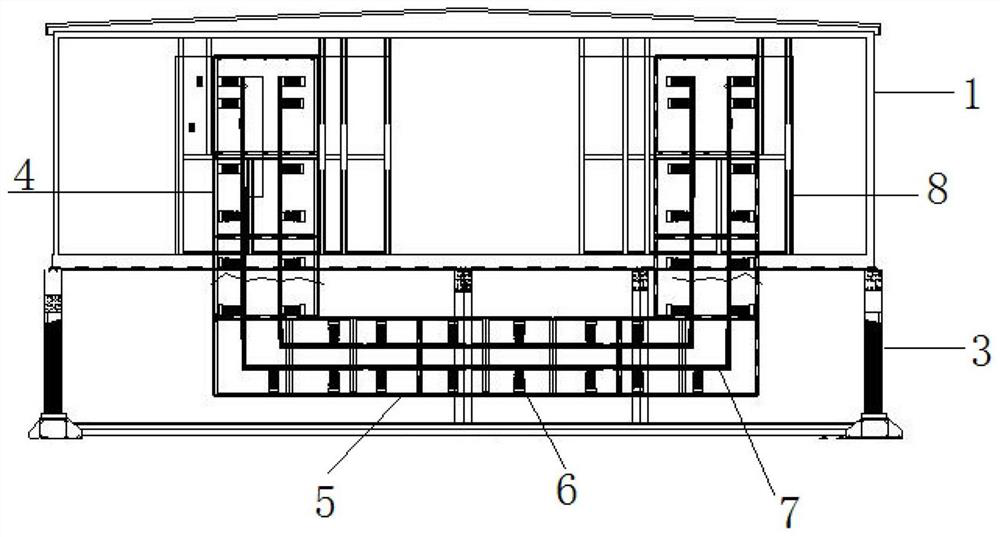

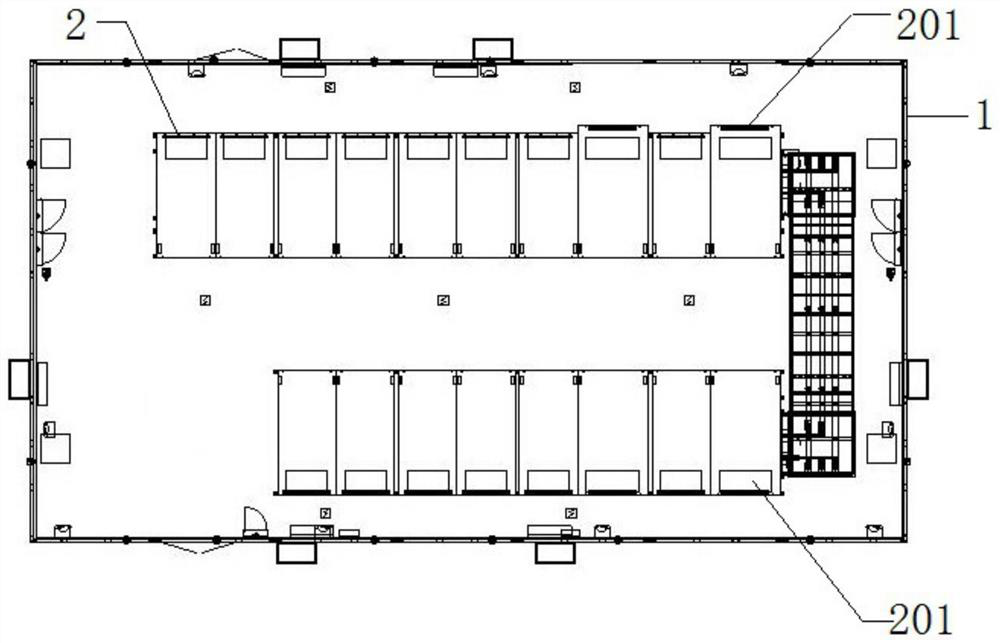

[0023] In order to understand the above-mentioned purposes, features and advantages of the present application more clearly, the following in conjunction with the attached Figure 1-2 and specific embodiments to further describe the present application in detail. It should be noted that, under the condition of not conflicting with each other, the embodiments of the present application and the features in the embodiments can be combined with each other.

[0024] A new type of high-pressure prefabricated cabin busbar bridge, including a side connecting frame 4 and a bottom connecting frame 5, both of which are frame structures and fully spliced connections; the bottom connecting frame 5 is located inside the bottom foundation frame 3 of the high-pressure prefabricated cabin 1 , the side connecting frame 4 is located on one side of the high-voltage cabinet 2, passes through the bottom plate of the high-pressure prefabricated cabin 1, and is connected to the bottom connecting fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com