Track fixing device

A fixing device and track technology, applied in the direction of track system, transportation and packaging, load hanging components, etc., can solve the problems of troublesome construction, high cost, unreasonable structure, etc., and achieve the effect of solving height problems and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

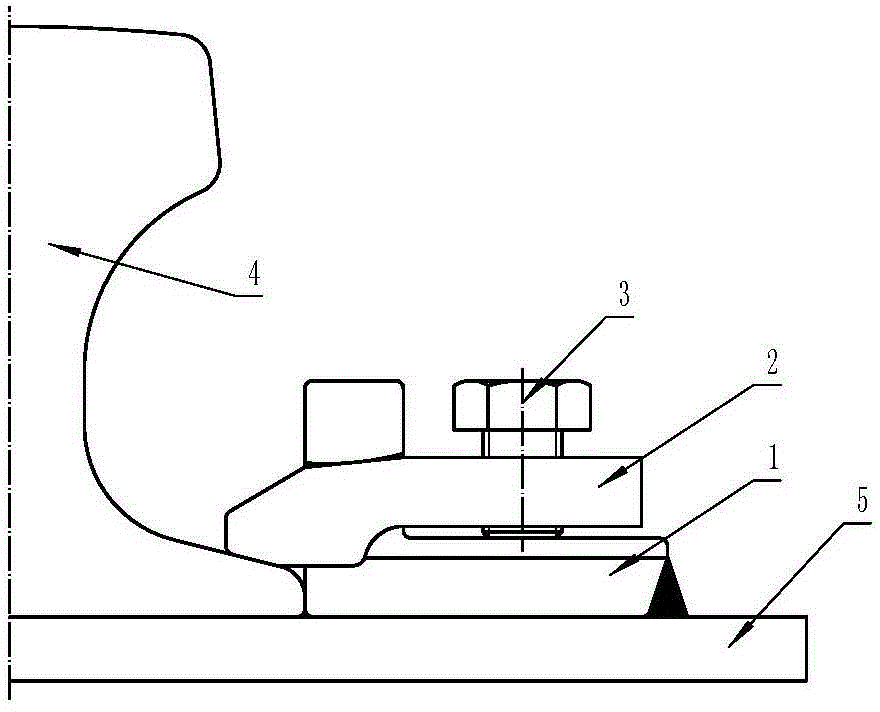

[0010] In Embodiment 1, the base 1 is L-shaped and its lower part is welded on the crane beam 5. There is a crossbeam at the front of the base 1. The front part of the pressure plate 2 is placed under the crossbeam of the base 1 and presses the rail 4. Threaded through hole, the screw 3 passes through the threaded through hole on the pressure plate 2, and the head of the screw 3 is pushed on the base 1 rear part. In this embodiment, the beam of the base 1 stretches to both sides, the pressing plate 2 is U-shaped, and the two ends of the pressing plate 2 protrude from the lower part of the base 1 beam to press the rail 4 .

Embodiment 2

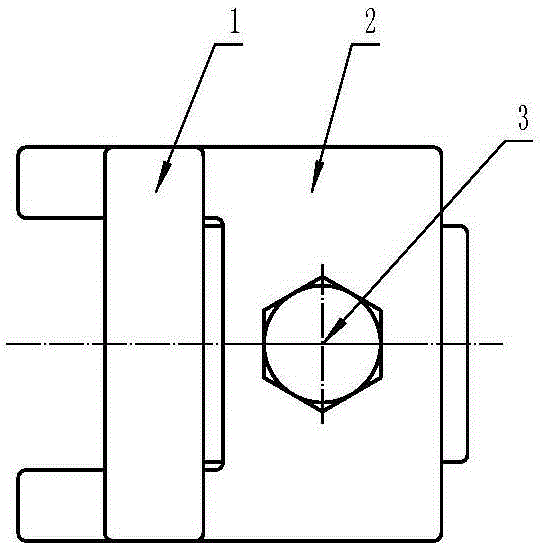

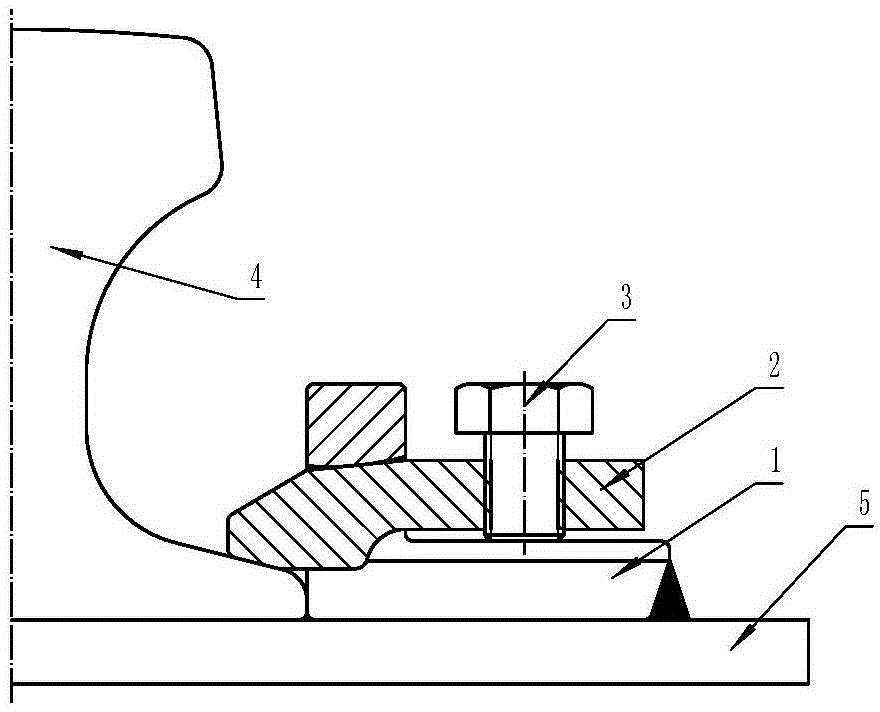

[0011] In the second embodiment, the base 1 is L-shaped and its lower part is welded on the crane beam 7. There is a crossbeam at the front of the base 1. The front part of the pressure plate 2 is placed under the crossbeam of the base 1 and presses the rail 4. Threaded through hole, the screw 3 passes through the threaded through hole on the pressure plate 2, and the head of the screw 3 is pushed on the base 1 rear part. In this embodiment, the crossbeam of the base 1 is arranged in the middle, the pressing plate 2 is T-shaped, and the lower part of the head base 1 crossbeam of the pressing plate 2 stretches out to press the rail 4 . In this embodiment, there are two threaded through holes on the pressing plate 2, and there are also two screws 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com