Servo motor driving type driving system model train acceleration device

A technology of servo motor and system model, which is applied in the direction of railway vehicle testing, etc., and can solve the problems of small scale ratio, economic loss, and insufficient length to arrange acceleration sections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical content of the patent of the present invention is further described below, but it is not a limitation to the substantive content of the patent of the present invention.

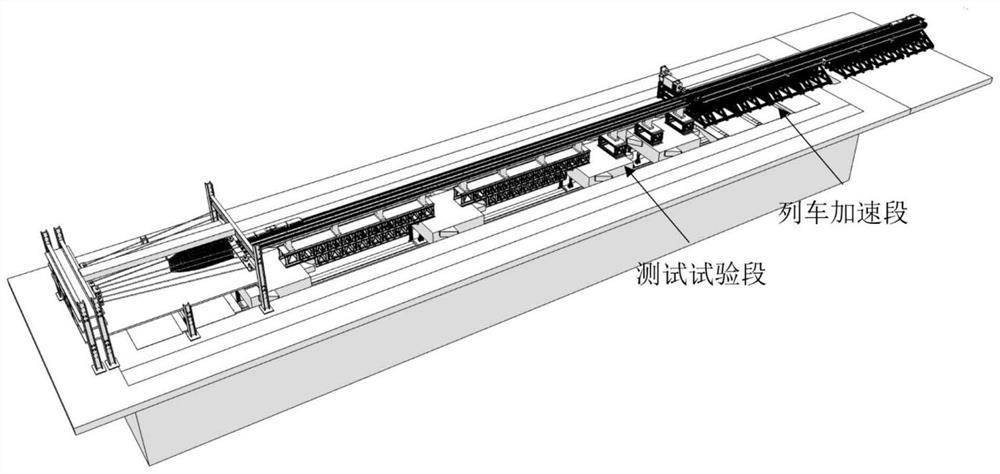

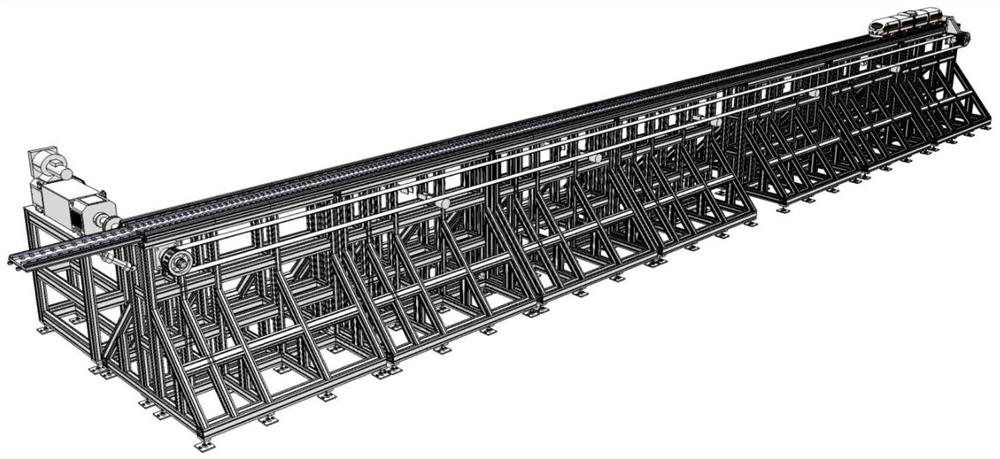

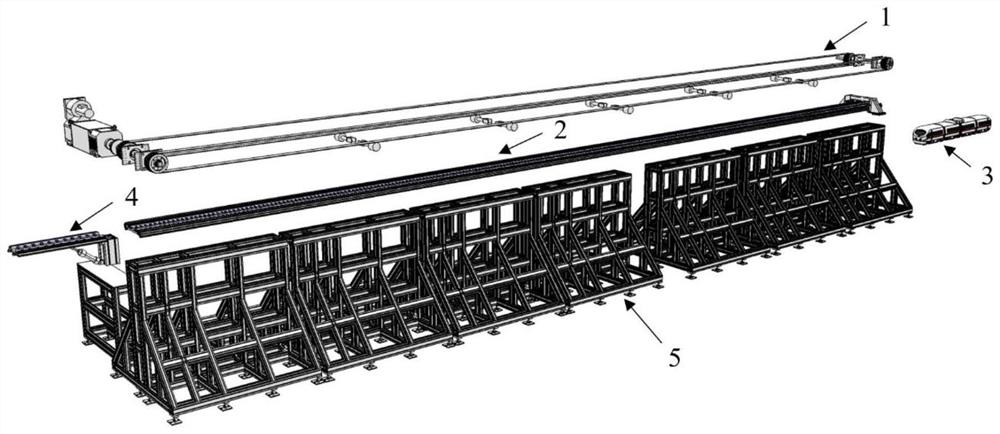

[0034] figure 1 It is a partial overview of the driving test system on the bridge, which only includes the test section and the train acceleration section closely connected with it. During the test, the model needs to have a certain speed before entering the test section. The motor drive system and the linking track system realize the safe, reliable and effective speed up of the model train. figure 2 is the overall overview of the train acceleration section, image 3 is the explosion diagram of the acceleration section, given by figure 2 , 3 It can be seen that the whole servo motor-driven driving system model train speed-up device is mainly composed of a servo motor drive system 1, an acceleration guidance system 2, a model train 3, a connecting track system 4, and a movable support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com