Pipeline bottom hollowing-out device and construction method

A technology for pipes and pipe jacking, which is applied to the field of hollowing devices at the bottom of pipes, can solve problems such as low efficiency and potential safety hazards, and achieve the effects of improving efficiency and being convenient and quick to fix.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

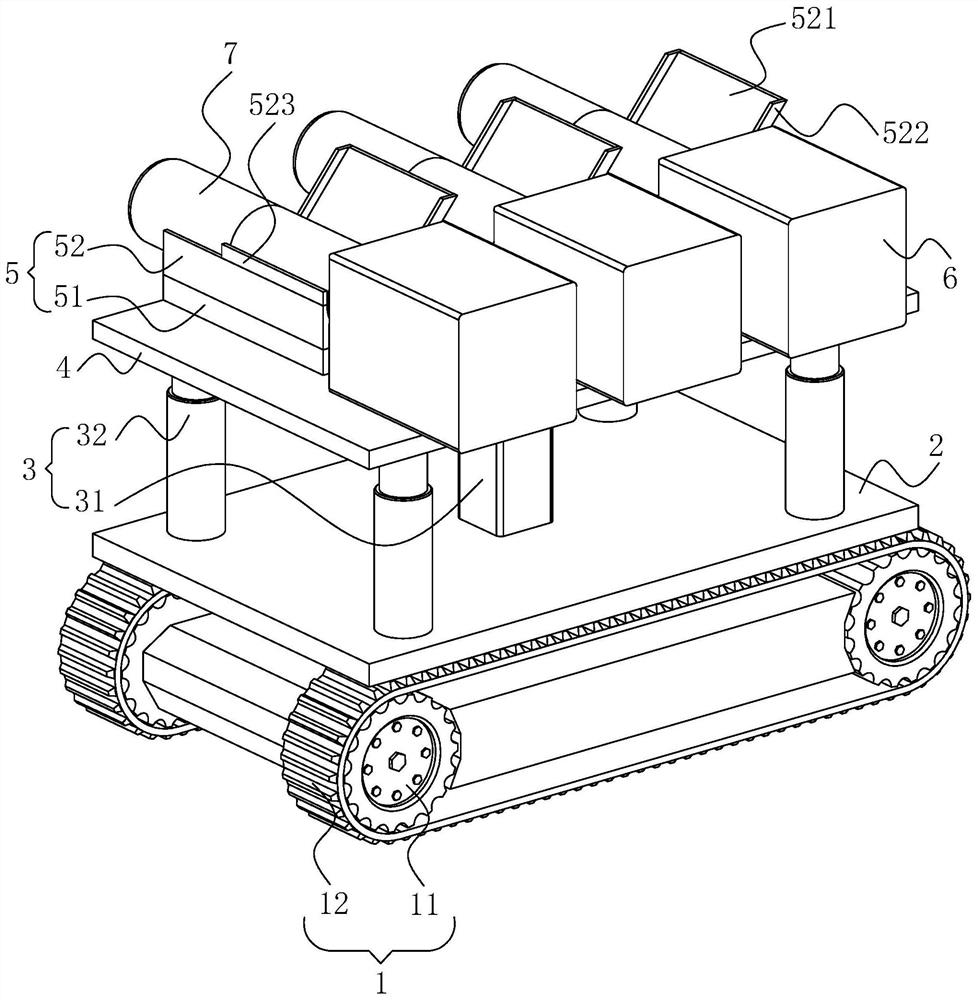

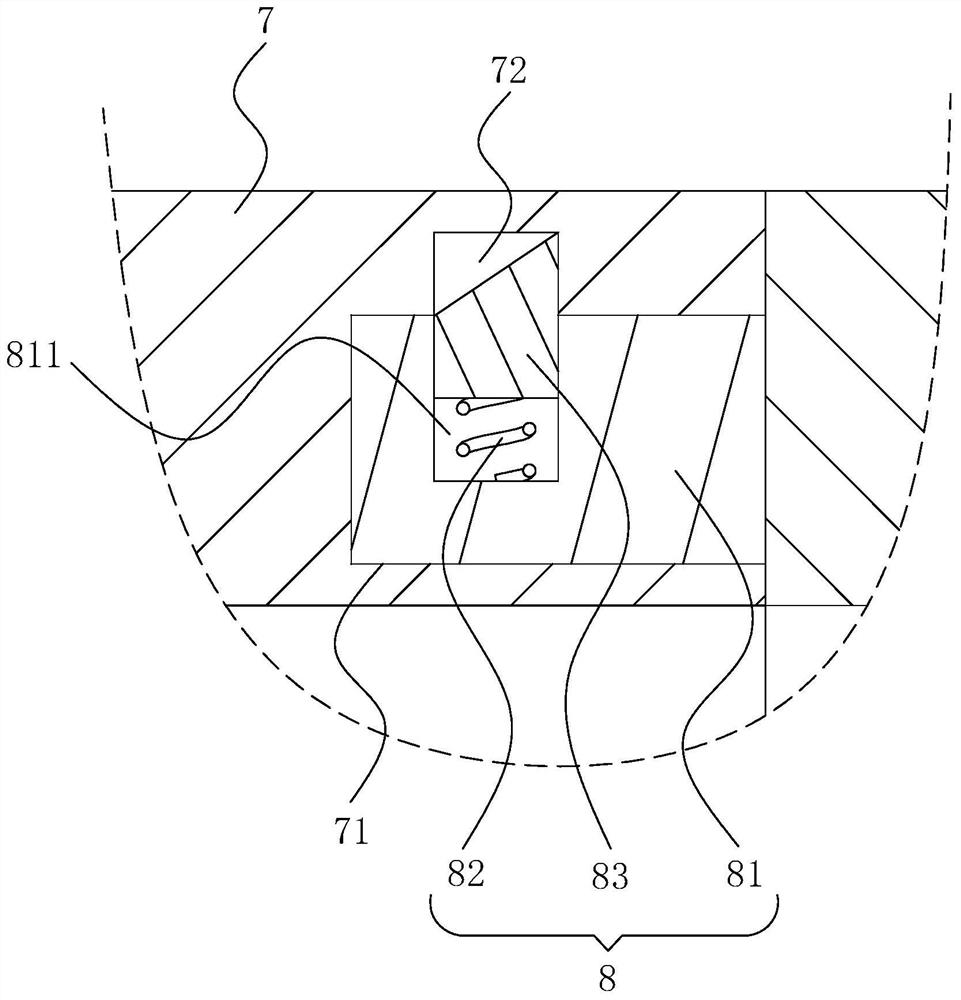

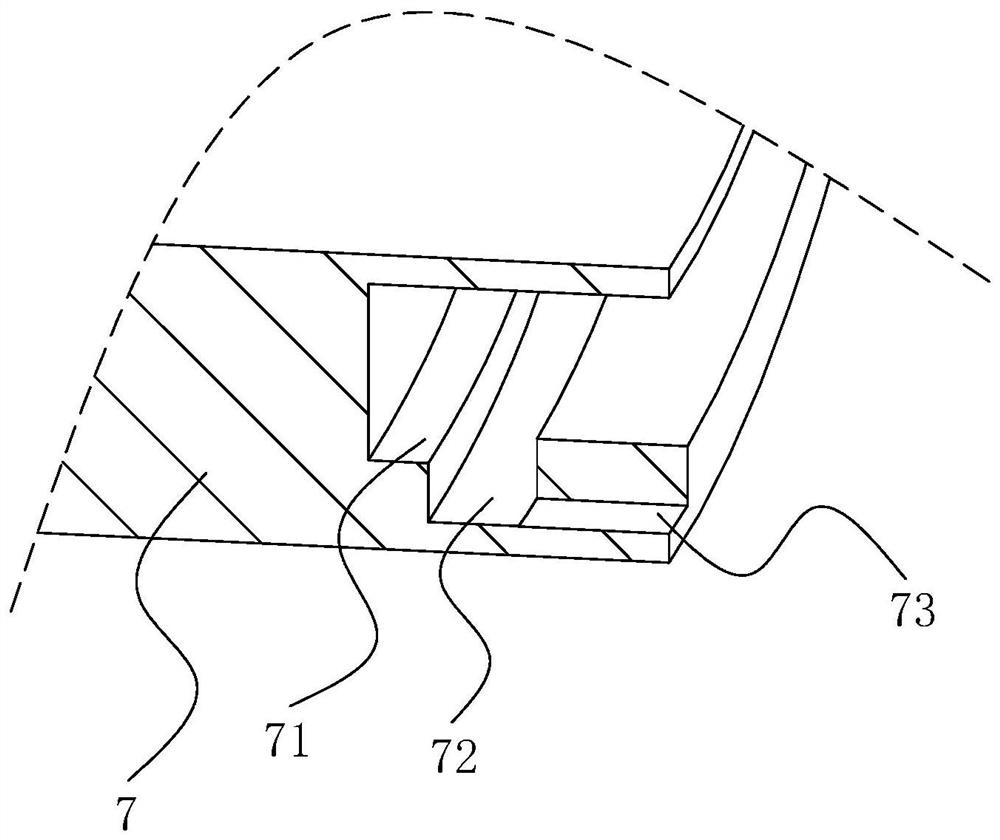

[0041] The following is attached Figure 1-3 The application is described in further detail.

[0042] The embodiment of the present application discloses a device for hollowing out the bottom of a pipeline.

[0043] refer to figure 1 The hollowing out device at the bottom of the pipeline comprises a moving mechanism 1 located at the bottom of the groove, a support plate 2 fixedly connected above the moving mechanism 1 and arranged horizontally, and an operation panel 4 located above the support plate 2 and arranged horizontally, the length direction of the pipeline Consistent with the width direction of the groove, the moving mechanism 1 allows the operation panel 4 to move along the width direction of the groove, and a lifting mechanism 3 for vertically lifting the operation panel 4 is provided between the support plate 2 and the operation panel 4. Several driving parts 6 and positioning assemblies 5 are fixed. In this embodiment, the driving parts 6 are oil cylinders, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com