A digging rod for installing heat exchange tubes

A technology of heat exchange pipe and excavation rod, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of low hole excavation efficiency, complex structure, poor sludge drainage efficiency, etc., so as to improve the excavation efficiency and quality. , to ensure the effect of construction quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

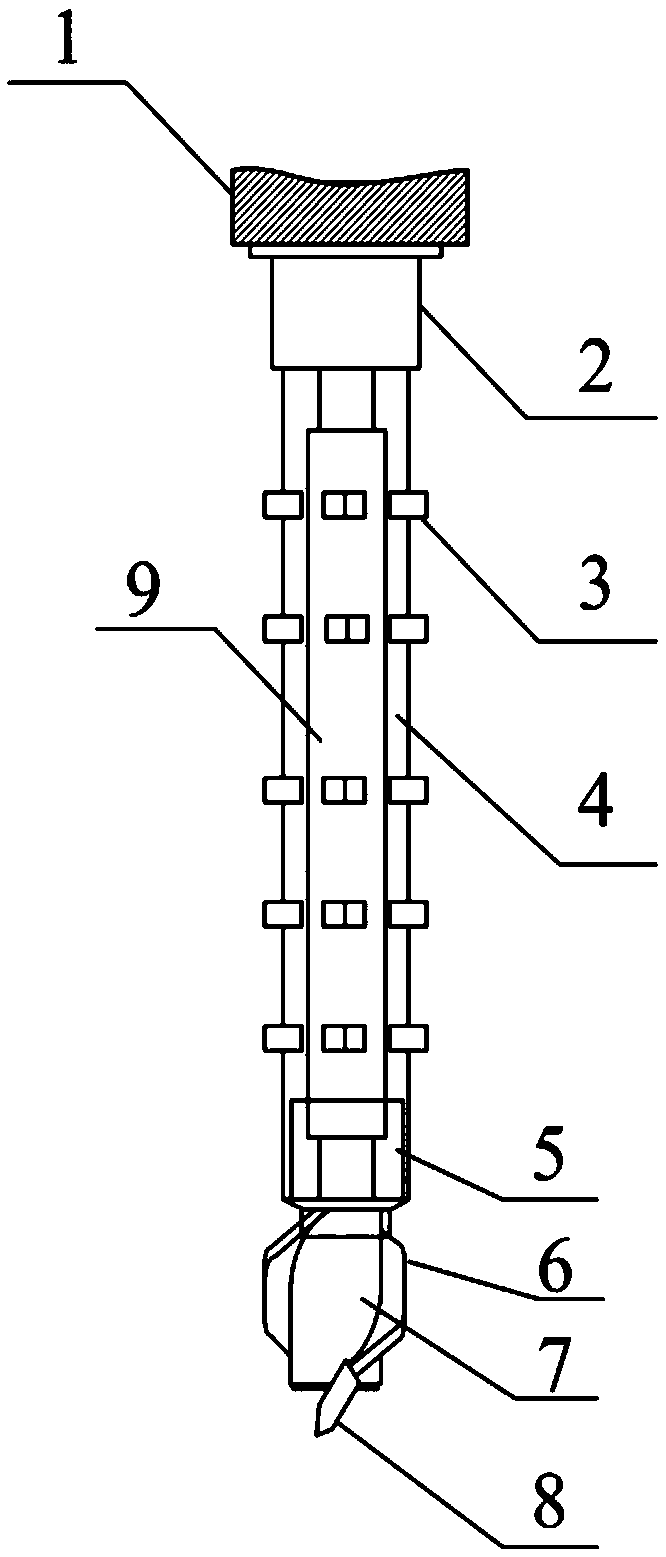

[0025] as attached figure 1 to attach image 3 shown

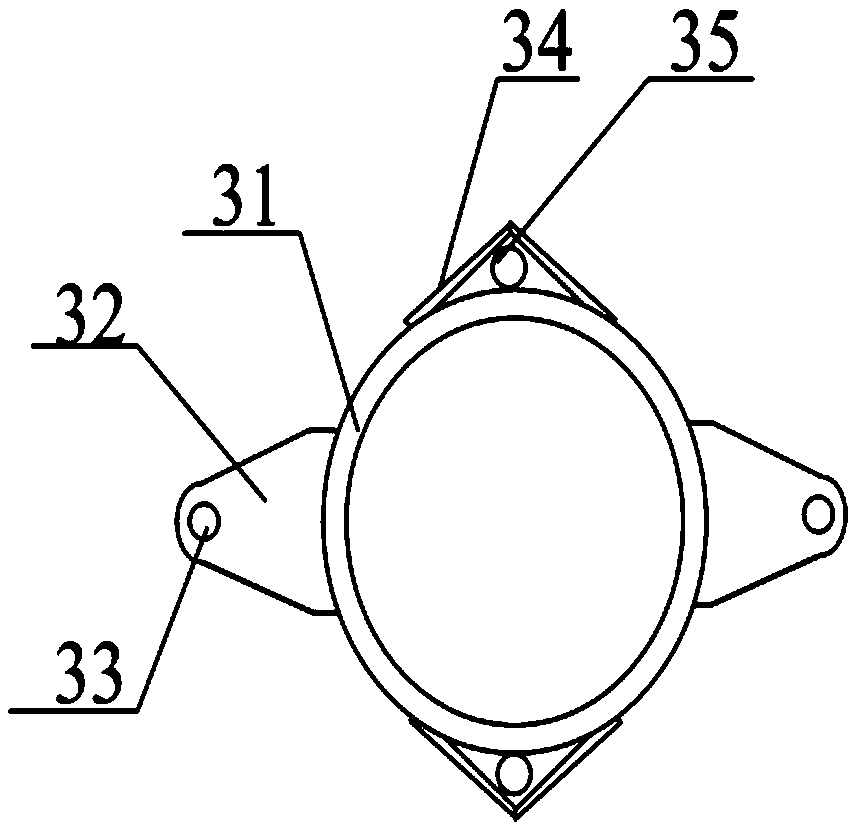

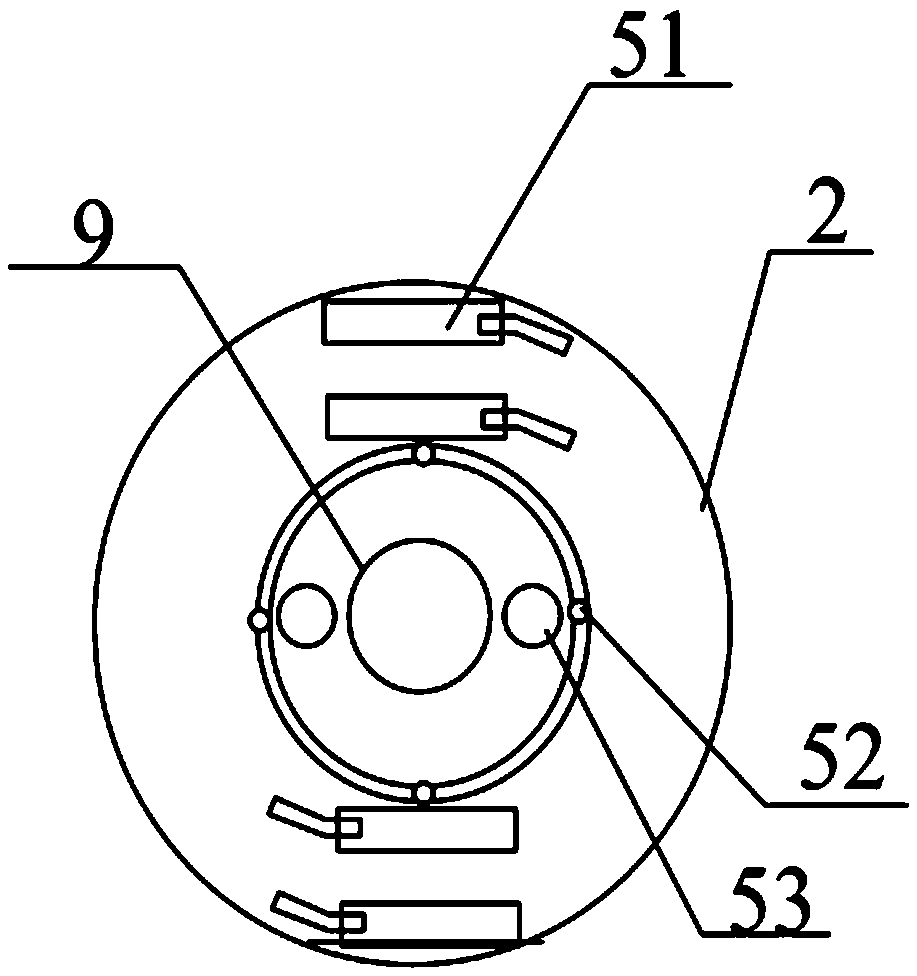

[0026] The invention provides a digging rod for installing heat exchange tubes, which includes a driving mechanism 1, a digging rod 2, a cleaning device 3, a pipe body 4, a ramming device 5, a drilling blade 6, a drill bit 7, a nozzle 8 and an installation Hole 9, the excavating rod 2 is installed at the bottom of the driving mechanism 1; the cleaning device 3 is installed in the middle of the pipe body 4; the hole tamping device 5 is installed at the bottom of the pipe body 4; the pipe body 4. An installation hole 9 is provided inside; the revolving blade 6 is installed on the outside of the drill bit 7; the nozzle 8 is installed on the lower end of the drill bit 7; the cleaning device 3 includes a pipe wall 31, a support plate 32, an end A hole cover 33, an outer cladding 34 and a drain pipe 35, two support plates 32 are installed outside the pipe wall 31; an end hole cover 33 is provided at the outer end of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com