Asphalt paver for building construction

A technology for building construction and paver, applied in construction, road, road repair and other directions, can solve problems such as failure to meet good paving, poor paving effect, etc., to ensure paving efficiency, shorten construction time, and ensure paving. The effect of the smoothing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

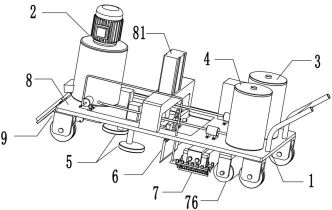

[0042] Such as figure 1 As shown, an asphalt paver for building construction includes a machine base 1, a multi-stage paving device mounted on the machine base 1, and a feeding assembly 2 arranged on the machine base 1, a material storage assembly 3 and The heating component 4 and the multi-stage paving device include a pendulum wiper mechanism 5, a horizontal wiper mechanism 6 and a longitudinal wiper mechanism 7 that are successively and adjacently installed in the machine base 1. The pendulum wiper mechanism 5 is used for swinging paving and feeding materials The bitumen discharged from the component 2, the storage component 3 is used to supplement the bitumen for the supply component 2.

[0043] Specifically, the feeding assembly 2 is used to discharge asphalt, and the heating assembly 4 can heat the asphalt in the feeding assembly 2, so as to prevent the asphalt stored in the feeding assembly 2 from drying up and affect the normal operation of asphalt laying. .

[0044]...

Embodiment 2

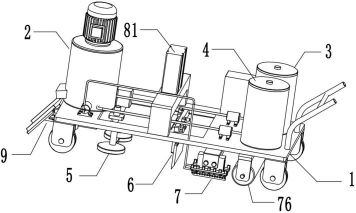

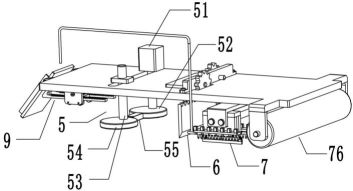

[0068] Such as figure 2 and image 3 As shown, the difference from Embodiment 1 is that, further, a support shaft 53 is vertically arranged on the side of the rotating shaft. 54, the auxiliary disc 54 and the eccentric disc 52 are connected through a telescopic assembly 55.

[0069] Specifically, the auxiliary disc 54 is arranged non-coaxially with the support shaft 53, so as to cooperate with the eccentric disc 52 to realize the swing paving of asphalt.

[0070] Such as Figure 4 As shown, further, the telescoping assembly 55 includes a sleeve 551 connected to one of the eccentric disc 52 or the auxiliary disc 54, an insertion rod 552 cooperating with and sliding through the sleeve 551, and a joint connected to the sleeve 551 and the insertion rod 551. The spring 553 between the rods 552 , the end of the insertion rod 552 away from the sleeve 551 is connected to one of the auxiliary disc 54 or the eccentric disc 52 .

[0071] Specifically, the sleeve 551 and the insertio...

Embodiment 3

[0073] Such as Figure 5 As shown, the difference from Embodiment 1 and Embodiment 2 is that further, two groups of scrapers 63 are driven by a group of driving members 62 to move toward each other through a transmission assembly.

[0074] Specifically, the transmission assembly may adopt an existing structure capable of power transmission.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com