A kind of photocurable composition for brightening film

A technology of composition and brightening film, which is applied in the field of optical film, can solve the problems of high operating cost and demanding conditions, difficulty in controlling the uniformity of the inorganic layer, and is limited to about 1.6, so as to achieve high light source utilization rate, shorten curing time, The effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] In the present invention, the preparation method of the polythiol compound preferably includes the following steps:

[0039] (1) Heat the polythiol monomer to 50-80°C, add a photoinitiator, cool the resulting mixture to room temperature, add allicin to the cooled mixture for photocuring modification, and obtain a modified polythiol monomer body;

[0040] (2) reacting the modified polythiol monomer in the step (1) with sulfur to obtain a polythiol compound.

[0041] In the present invention, the polythiol monomer is preferably heated to 50-80°C, a photoinitiator is added, the obtained mixture is cooled to room temperature, and allicin is added to the cooled mixture for photocuring modification to obtain the modified polythiol monomer body. In the present invention, the polythiol monomer preferably includes 4-mercaptomethyl-1,8-dimercapto-3,6-dithiooctane, 2,3-di(2-mercaptoethylthio )-3-propane-1-thiol, tetrakis(mercaptomethyl)methane, bis(2-(2-mercaptoethylthio)-3-mer...

Embodiment 1

[0063] Weigh 146.4g of pentaerythritol tetrakis (3-mercaptopropionic acid) ester monomer, heat 80°C in a water bath, then add 0.293g (2‰) photoinitiator diphenyl-(2,4,6-trimethylbenzyl Acyl)phosphine (TPO), mix well and dissolve completely, add 12.15g of allicin after cooling to room temperature, and irradiate with ultraviolet light for a certain period of time to obtain trithiopropenyl pentaerythritol tetrakis (3-mercaptopropionic acid) ester mono body.

[0064] Weigh 195g trithiopropenyl pentaerythritol tetrakis(3-mercaptopropionate) monomer, heat it to 90°C in an oil bath, add 4.8g sulfur solid in 3 batches, react for 3h, and obtain the target polythiol compound after cooling. Trithiopropenyl pentaerythritol tetrakis(3-mercaptopropionate) sulfide.

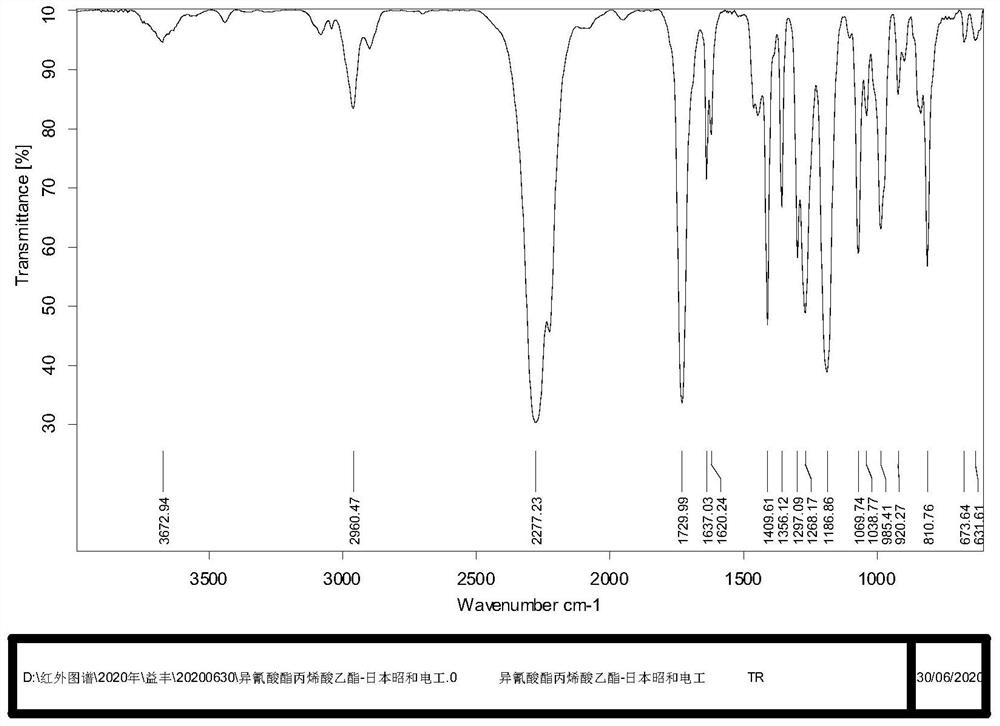

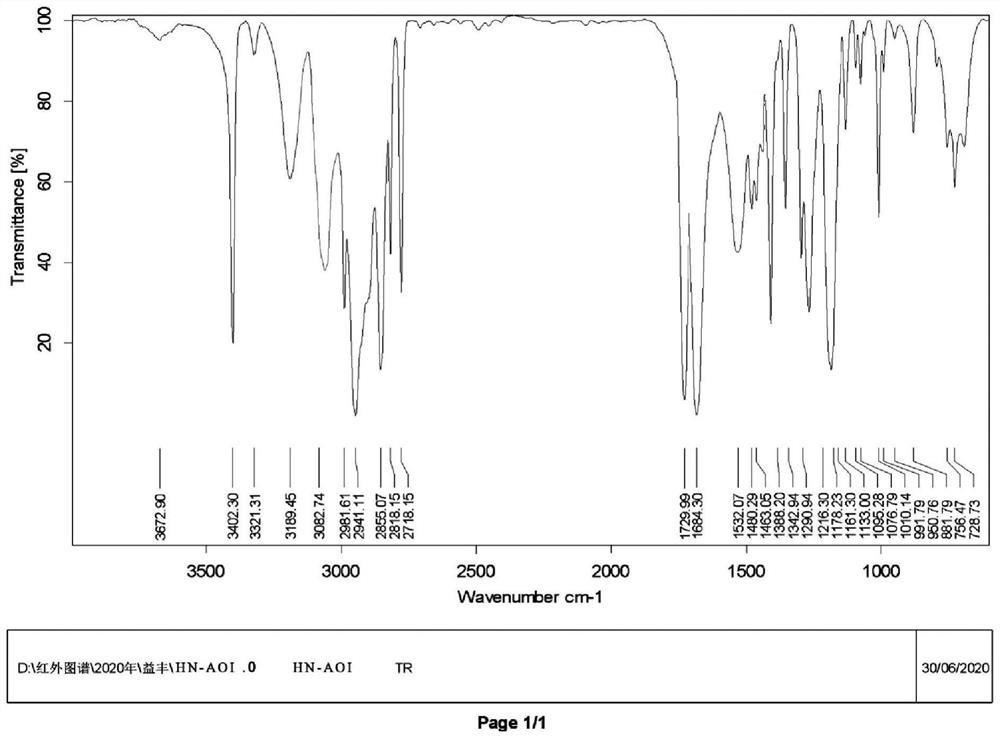

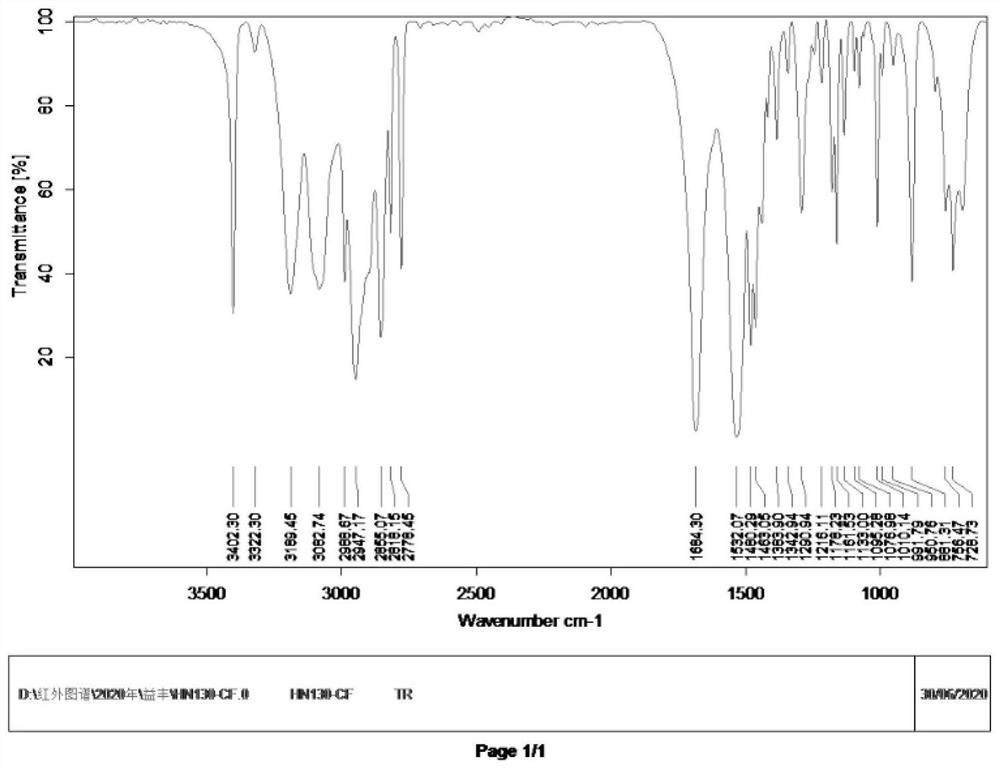

[0065] Preparation of anti-yellowing agent HN-AOIVM3: Weigh 12.5g of AOI-VM monomer, heat in oil bath to 80°C, then add 14.4g of HN130 in 5 batches and mix evenly, react for 2h, stop the reaction, cool to room temperature Avai...

Embodiment 2

[0069] Weigh 146.4g of pentaerythritol tetrakis (3-mercaptopropionic acid) ester monomer, heat in a water bath at 50°C, then add 0.293g (2‰) photoinitiator TPO, mix evenly and dissolve completely, add 12.15g of garlic after cooling to room temperature The element can be irradiated with ultraviolet light for a certain period of time to obtain trithiopropenyl pentaerythritol tetrakis (3-mercaptopropionate) monomer.

[0070] Weigh 195g trithiopropenyl pentaerythritol tetrakis(3-mercaptopropionate) monomer, heat it in an oil bath to 90°C, add 4.8g sulfur solid in 5 batches, react for 3h, and obtain the target polythiol compound after cooling. Trithiopropenyl pentaerythritol tetrakis(3-mercaptopropionate) sulfide.

[0071] Preparation of anti-yellowing agent HN-AOIVM3: Weigh 12.5g of AOI-VM monomer, heat it in an oil bath to 80-100°C, then add 14.4g of HN130 in 5 batches and mix well, react for 2 hours, stop the reaction, and cool to The liquid anti-yellowing agent HN-AOIVM3 can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com