Wool felt-resistant two-component water-based paint and preparation method thereof

A water-based coating, two-component technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of high price and application limitations of high-performance products, achieve superior performance, simplify construction methods, and reduce system gloss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Two-component water-based paint consists of A and B components.

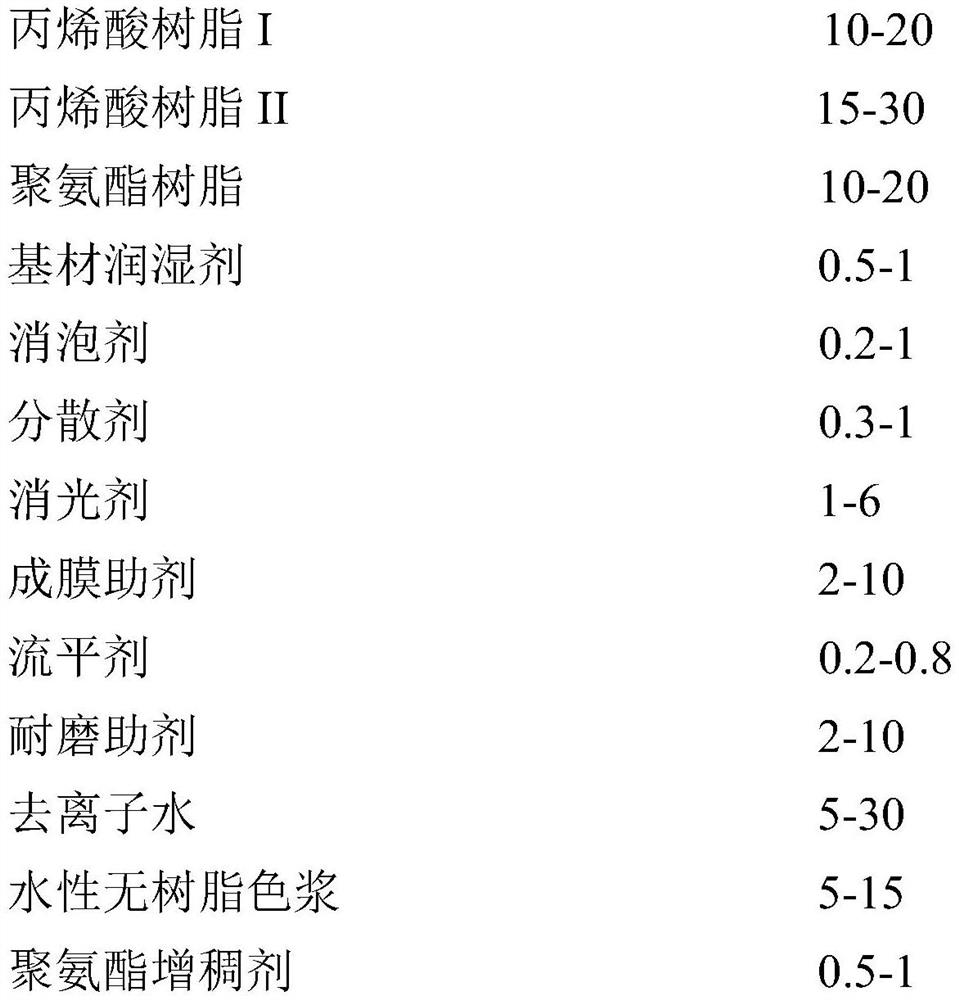

[0032] A and B components are composed in parts by weight as follows:

[0033] Component A

[0034]

[0035]

[0036] Component B

[0037] Bayhydur XP2655 14.3

[0038] The manufacturing method of the coating is as follows: the two-component water-based coating is prepared from component A and component B. The preparation process of component A is as follows: first add resin, then add substrate wetting agent, defoamer, dispersant, film-forming aid, deionized water and disperse evenly, add matting agent and disperse until fine If the degree is qualified, add leveling agent, deionized water, wear-resistant additive, thickener, and color paste under stirring state, and disperse evenly; discharge, component A is completed; component B is BayhydurXP2655 water-based curing agent from Bayer.

[0039] Stir and mix components A and B evenly at a weight ratio of 7:1, adjust to a suitable spray viscosity w...

Embodiment 2

[0042] Two-component water-based paint consists of A and B components.

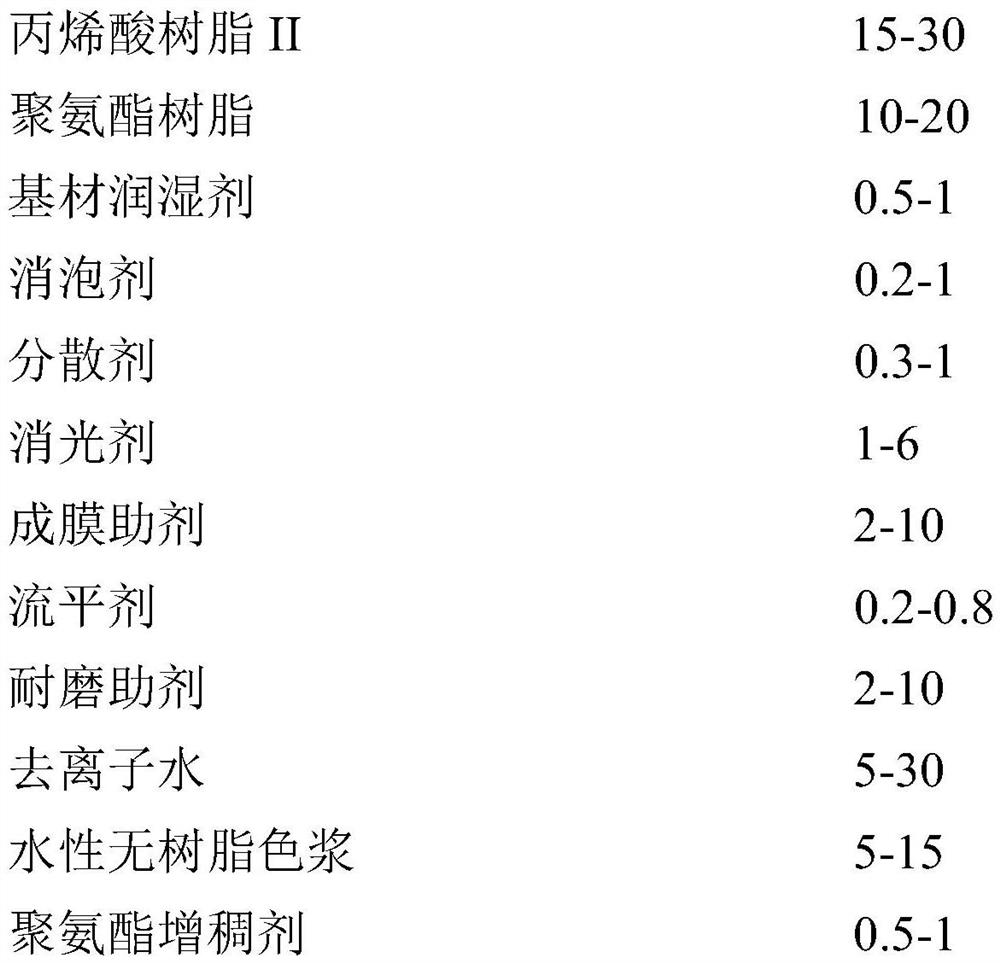

[0043] A and B components are composed in parts by weight as follows:

[0044] Component A

[0045]

[0046]

[0047] Component B

[0048] Bayhydur XP2655 20.0

[0049] Paint preparation method: Two-component water-based paint is prepared from component A and component B. The preparation process of component A is as follows: first add resin, then add substrate wetting agent, defoamer, dispersant, film-forming aid, deionized water and disperse evenly, add matting agent and disperse until fine If the degree is qualified, add leveling agent, deionized water, wear-resistant additive, thickener, and color paste under stirring state, and disperse evenly; discharge, component A is completed; component B is Bayhydur XP2655, a water-based curing agent from Bayer.

[0050] Stir and mix components A and B evenly at a weight ratio of 7:1, adjust to a suitable spray viscosity with deionized water, and spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com