A recycling treatment system and treatment process of coated sand precision casting waste sand

A technology of precision casting and processing system, which is applied in the direction of cleaning/processing machinery, manufacturing tools, casting molding equipment, etc. Achieve the effect of extending the drying path, prolonging the drying time, and avoiding accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

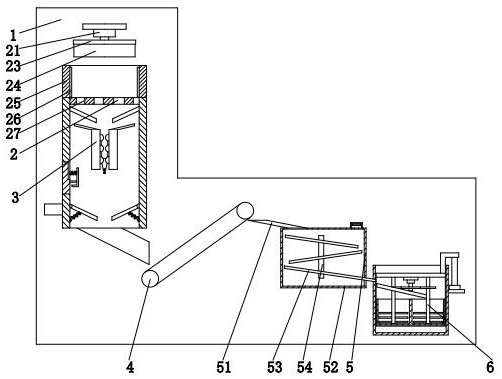

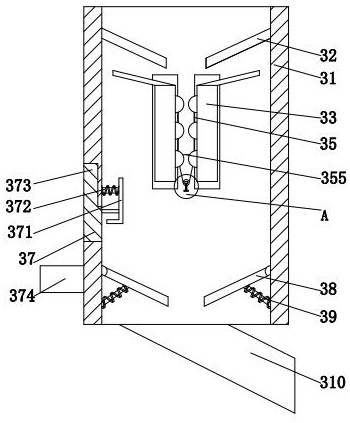

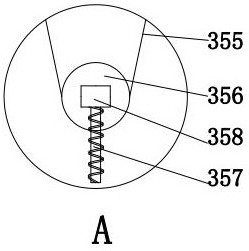

[0037] like Figure 1 to Figure 10 As shown, a waste sand reuse treatment system for coated sand precision casting includes a workbench 1, a cutting mechanism 2, a crushing mechanism 3, an electric conveyor belt 4, a heating evaporation mechanism 5, and a rinsing mechanism 6. The workbench 1 The cutting mechanism 2 and the crushing mechanism 3 are arranged from top to bottom, and the cutting mechanism 2 and the crushing mechanism 3 are connected to each other. The right side of the crushing mechanism 3 is installed on the workbench 1 from left to right. The heating evaporation mechanism 5 and the rinsing mechanism 6 , and an electric conveyor belt 4 is installed between the pulverizing mechanism 3 and the heating and evaporating mechanism 5 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com