Pin cutting machine for electronic buzzer processing

A technology of buzzer and foot cutting machine, which is applied in the field of foot cutting machine for electronic buzzer processing. It can solve the problems of lead deviation, cutting foot error, and irregular length of cutting foot, etc., so as to improve the correction efficiency, The effect of reducing the number of spins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

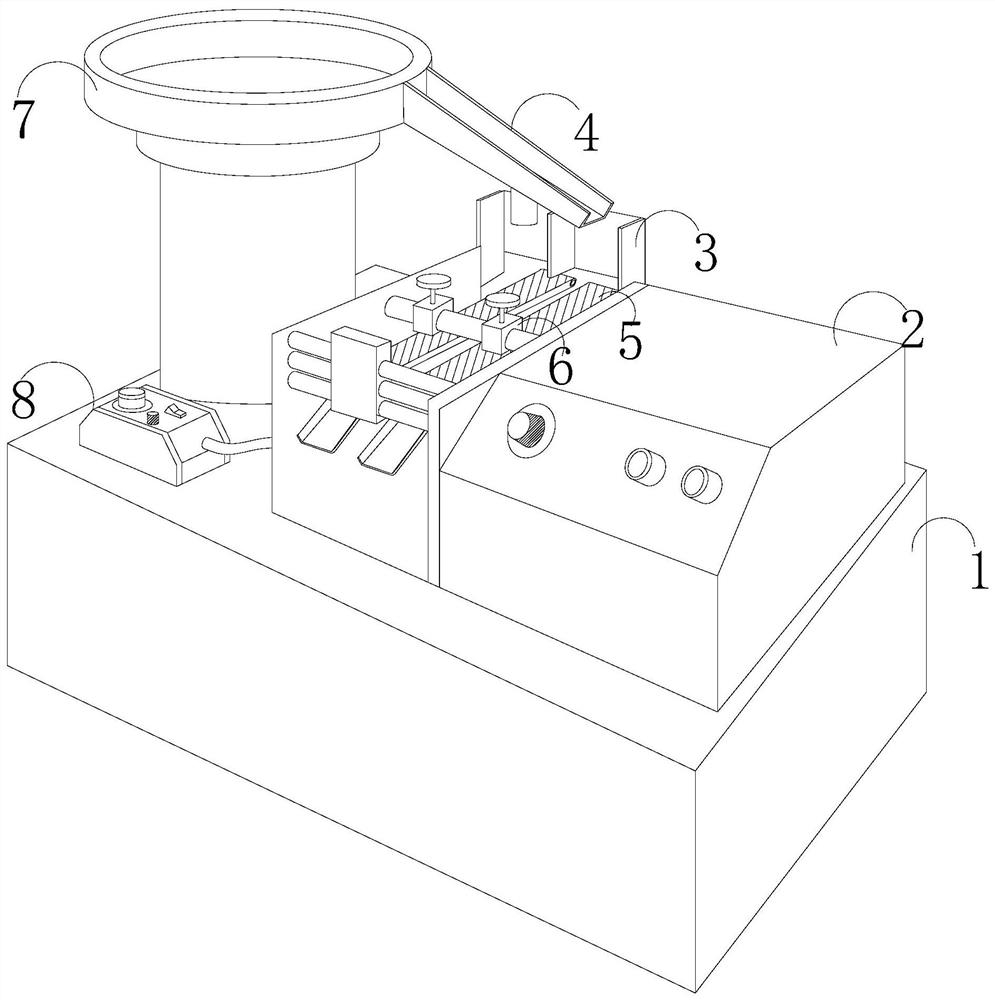

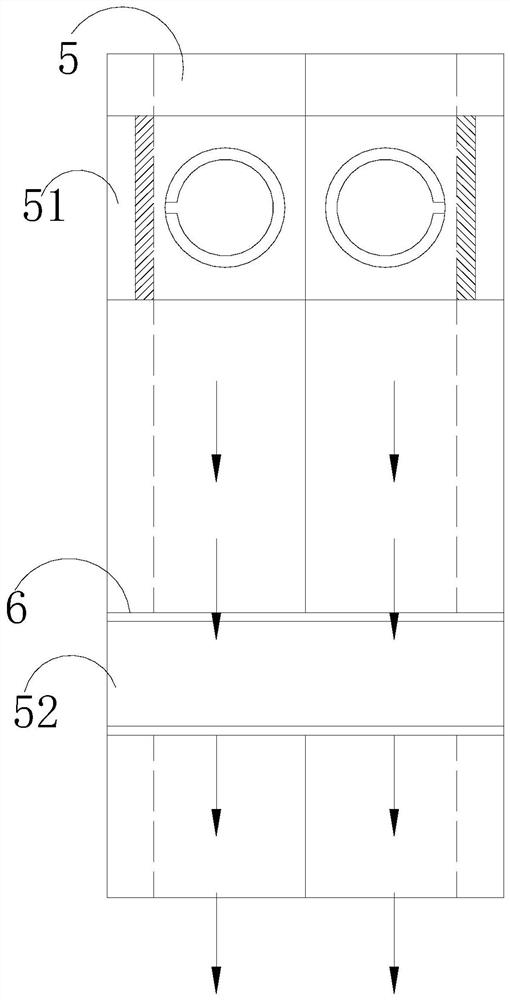

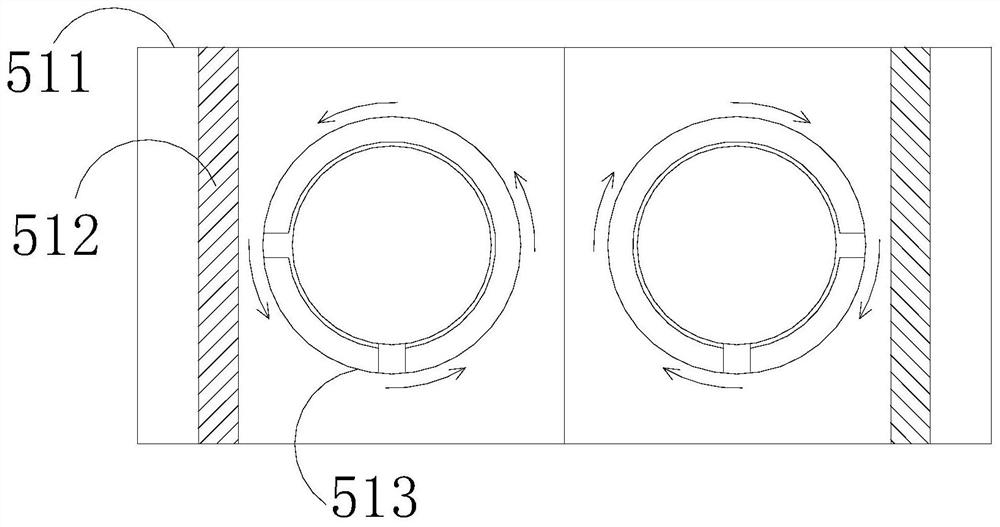

[0028] Such as Figure 1-Figure 7 As shown, the present invention provides a cutting machine for electronic buzzer processing, and its structure includes a base 1, a cabinet 2, a blanking baffle 3, a blanking port 4, a feeding belt 5, a cutting piece 6, and a loading tray 7. The controller 8, the base 1 is equipped with an organic case 2, the case 2 is electrically connected to the controller 8, the loading tray 7 is provided with a feeding port 4, and the feeding port 4 is connected to the feeding port The belt 5 cooperates, and the feeding belt 5 is mechanically connected with a blanking baffle 3, and the feeding belt 5 is provided with a cutting part 6, and the cutting part 6 is driven by the chassis 2, and is controlled by a controller 8, The feeding belt 5 is provided with a straightening mechanism 51 and a protective device 52 , the straightening mechanism 51 cooperates with the discharge opening 4 , and the bottom of the cut foot member 6 is equipped with a protective d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com