Configuration scheme and task scheduling method for multiple elevators of three-dimensional warehouse

A technology of task scheduling and configuration scheme, which is applied in the fields of industrial automation and logistics to achieve the effect of overcoming flexibility, increasing flexibility and improving utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

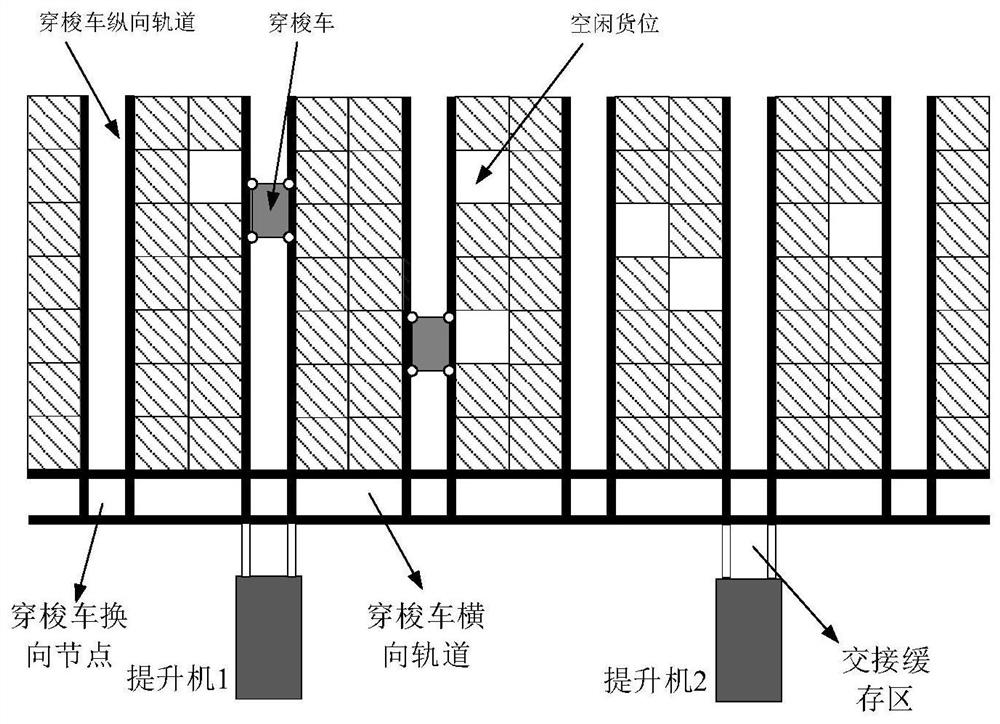

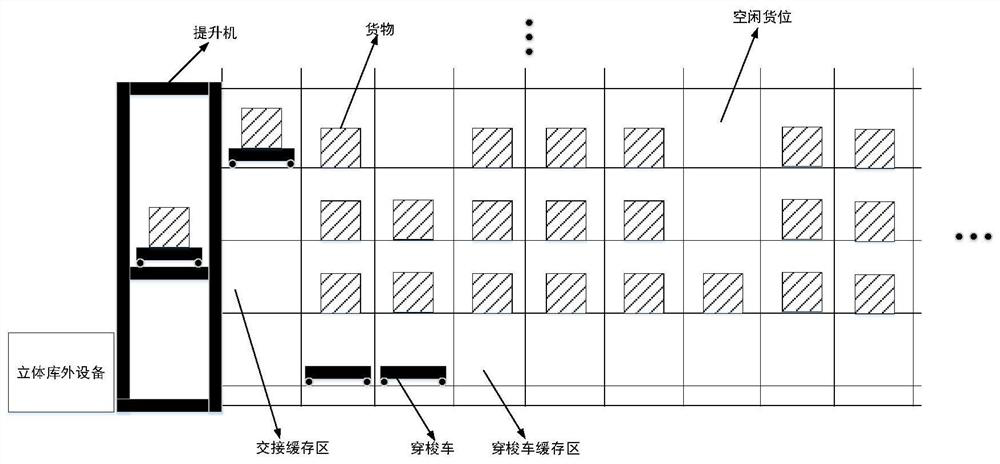

[0047] First establish the XYZ three-axis coordinate model of the three-dimensional library, that is, the number of rows is the X axis, from 0 to W from left to right, W is the maximum number of rows; the number of columns is the Z axis, from 0 to L from front to back, and L is the largest column number; the number of layers is the Y axis, from 0 to H from bottom to top, and H is the highest number of layers.

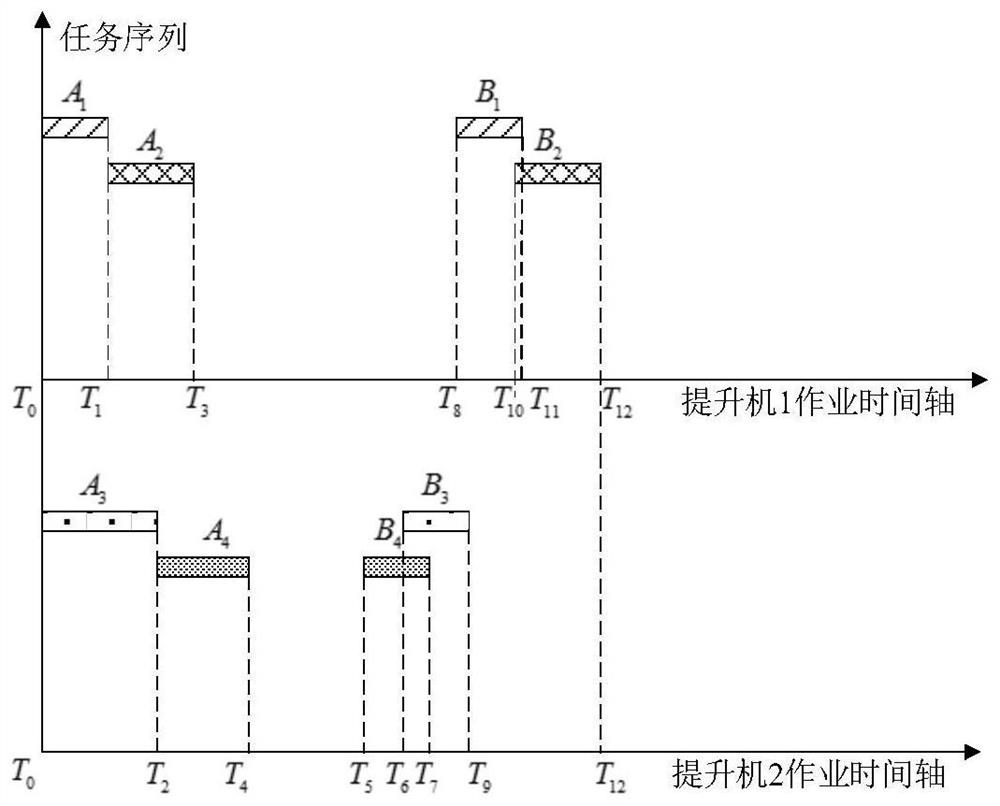

[0048] Then the movement time consumption model of the hoist and the shuttle car is established, the formula (1) is the movement time consumption model of the shuttle car, and the formula (2) is the movement time consumption model of the hoist:

[0049]

[0050]

[0051] where S S is the horizontal and vertical movement distance on the track obtained by formulas (3) and (4), S L is the movement distance of the hoist in the vertical direction. a S with v S is the acceleration and the maximum average speed of the shuttle car, a L with v L are the acceleration ...

Embodiment 2

[0097] Since the above method of randomly generating cargo locations is not common in the industry, the most common storage method in industrial production is fixed cargo locations, so this embodiment 2 conducts certain experiments on fixed cargo locations. The purpose is to further illustrate the practicability of this method. All the positions of the goods this time fall in the fourth cargo location area, and the locations are concentrated, corresponding to the fixed storage method in industrial production. The cargo locations are shown in Table 2.

[0098] Table 2

[0099] serial number Floor List Row serial number Floor List Row serial number Floor List Row serial number Floor List Row 1 1 24 1 11 1 24 2 21 1 24 3 31 1 24 4 2 2 24 1 12 2 24 2 22 2 24 3 32 2 24 4 3 3 24 1 13 3 24 2 23 3 24 3 33 3 24 4 4 4 24 1 14 4 24 2 24 4 24 3 34 4 24 4 5 5 24 1 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com