Component automatic recognition method for mechanical assembly process

A technology of mechanical parts and assembly process, which is applied in the field of parts identification, can solve problems such as out-of-roundness, burrs, and casts, and achieve high automation, strong robustness, simple and fast method principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

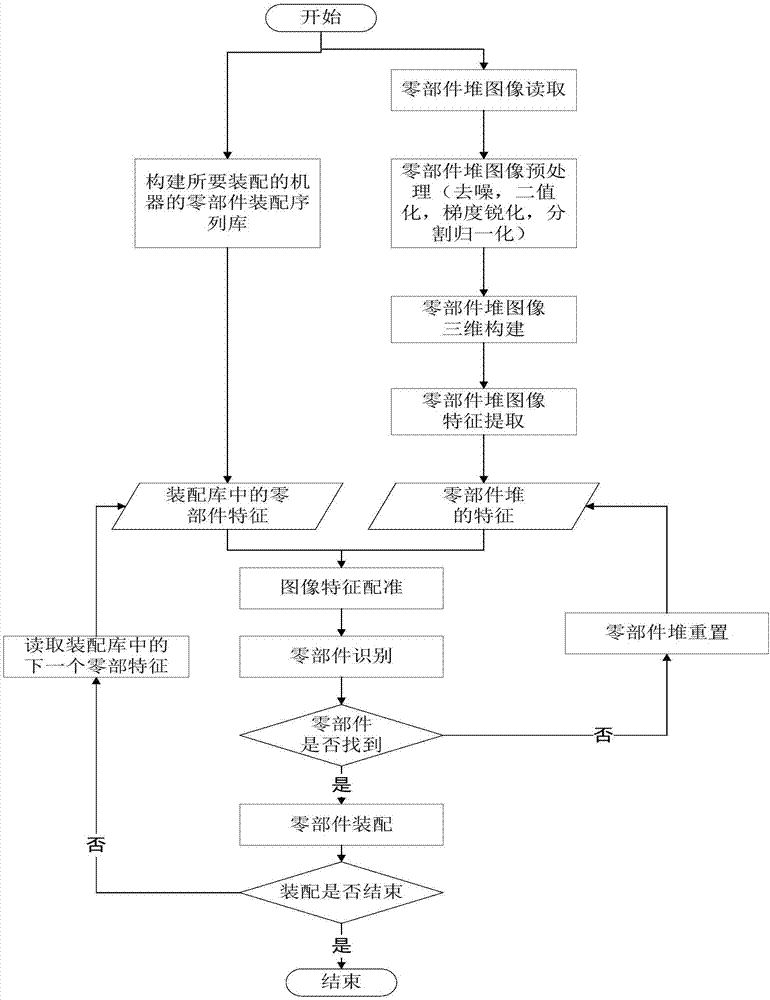

[0020] The invention discloses a method for automatic identification of components in the process of mechanical assembly. This method constructs the component feature library in the mechanical component assembly process, which is used to realize the full automation of mechanical assembly. During the mechanical assembly process, it can gradually extract the features of the parts to be assembled and the parts to be recognized Part features are registered and recognized until the assembly is completed, which saves the tedious steps of manually specifying the parts required for each step of assembly during the assembly process, which can greatly save the time of mechanical assembly. In addition, when replacing the assembly machine, since the component feature library has been built, we only need to replace the component features in the component feature library without replacing the expensive hardware in the assembly process, which can greatly save production costs . In the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com