Wet dust removal type energy-saving coal-fired boiler

A technology for wet dust removal and coal-fired boilers, applied in the field of coal-fired boilers, can solve problems such as difficult disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

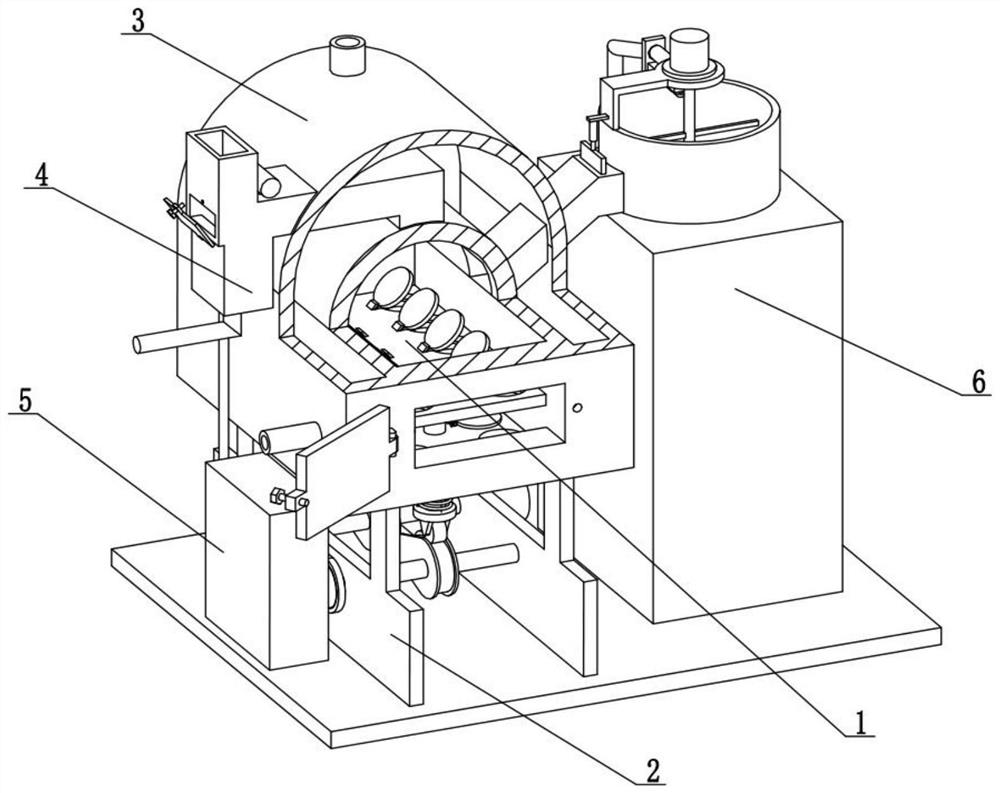

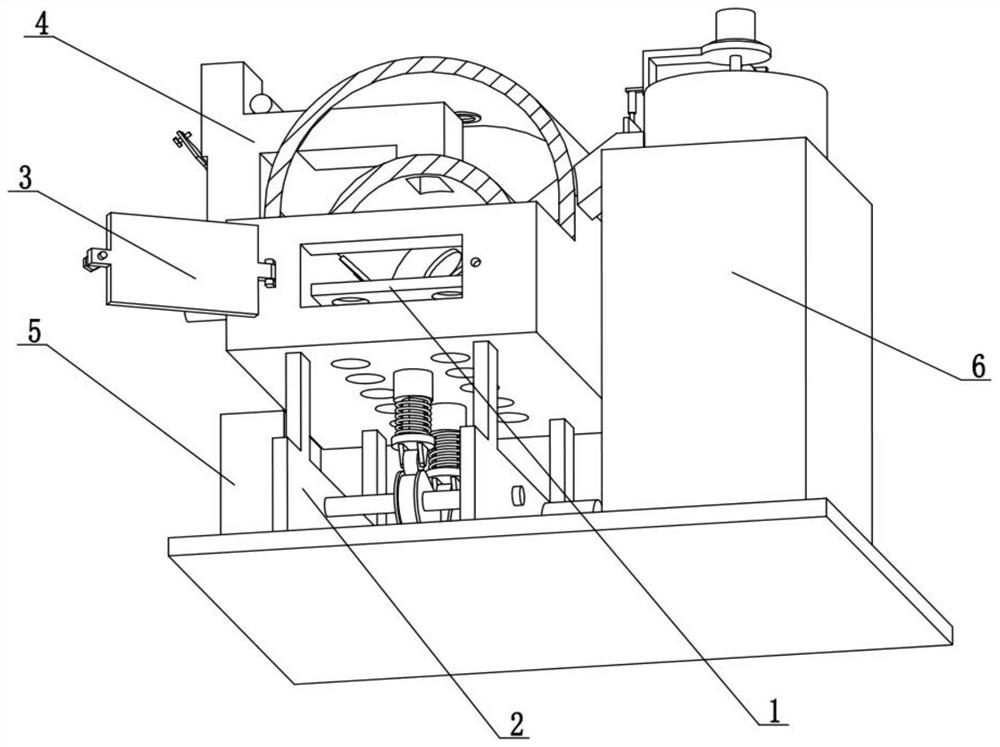

[0027] Combine below Figure 1-9 Describe this embodiment. The present invention relates to the technical field of coal-fired boilers, more specifically, a wet dust removal energy-saving coal-fired boiler, including a floating oxygen supply and leveling mechanism 1, a floating drive mechanism 2, a boiler body mechanism 3, and a dust removal chimney mechanism 4 , dust removal spray mechanism 5 and coal wet feeding mechanism 6, described dust removal spray mechanism 5 and coal wet feeding mechanism 6 are respectively fixedly connected to the left and right ends of the floating drive mechanism 2, and the boiler body mechanism 3 is fixedly connected to the floating drive mechanism 2 , the floating oxygen supply leveling mechanism 1 is slidingly connected in the boiler body mechanism 3, the coal wet feeding mechanism 6 is connected and communicated with the boiler body mechanism 3, the dust removal chimney mechanism 4 is connected and communicated with the boiler body mechanism 3, a...

specific Embodiment approach 2

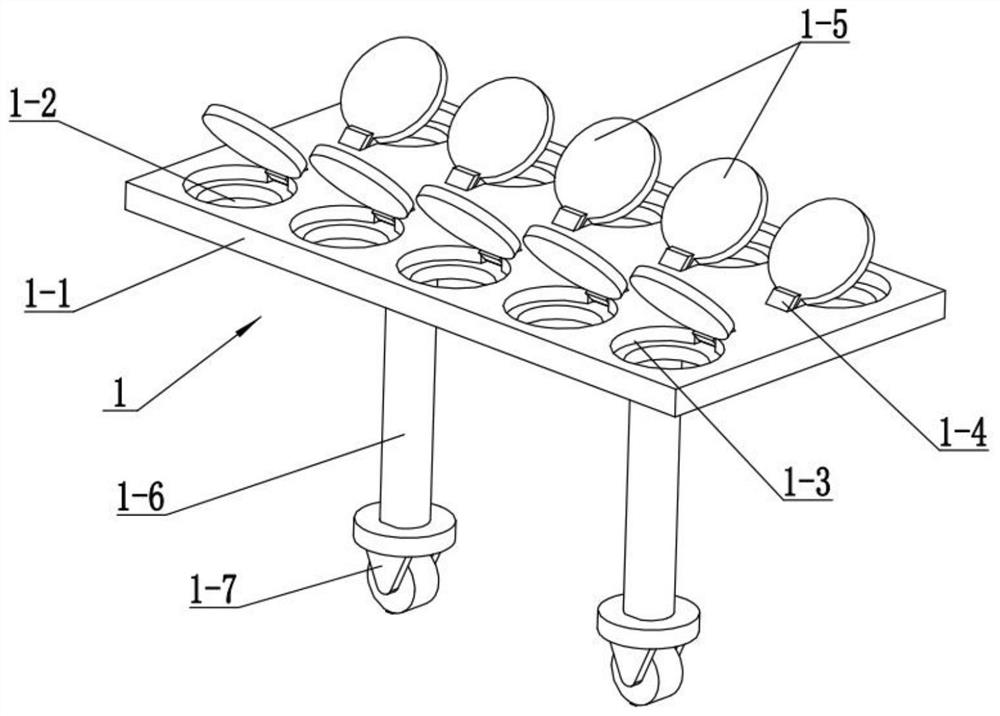

[0030] Combine below Figure 1-9Describe this embodiment, this embodiment will further explain the first embodiment, the floating oxygen supply leveling mechanism 1 includes a undulating plate 1-1, an air hole 1-2, an annular circular platform 1-3, an angle inclined plate 1-4, Cover 1-5, sliding rod 1-6 and contact wheel 1-7, two contact wheels 1-7 are respectively fixedly connected to the bottom of two sliding rods 1-6, and two sliding rods 1-6 are all fixedly connected to The bottom of the undulating plate 1-1, the undulating plate 1-1 is provided with a plurality of air holes 1-2, and the plurality of air holes 1-2 are all provided with an annular round table 1-3, and the plurality of shielding covers 1-5 are rotated respectively Connected to a plurality of annular round platforms 1-3, a plurality of angled inclined plates 1-4 are all arranged on the undulating plate 1-1, and a plurality of angled inclined plates 1-4 correspond to a plurality of shielding covers 1-5 respect...

specific Embodiment approach 3

[0033] Combine below Figure 1-9 Describe this embodiment, this embodiment will further explain the second embodiment, the floating drive mechanism 2 includes a bottom plate 2-1, a vertical vertical plate 2-2, a rotating shaft 2-3, a driving cam 2-4, a synchronous Sprocket 2-5 and driving motor 2-6, two vertical vertical plates 2-2 are all fixedly connected on the base plate 2-1, and two rotating shafts 2-3 are all rotationally connected to two vertical vertical plates 2- 2, two driving cams 2-4 are respectively fixedly connected to the middle of the two rotating shafts 2-3, and two synchronous sprockets 2-5 are respectively fixedly connected to the left ends of the two rotating shafts 2-3, and one of the rotating shafts 2-3 3 is fixedly connected on the output shaft of the drive motor 2-6, two synchronous sprockets 2-5 are driven by a chain, the drive motor 2-6 is fixedly connected on one of the vertical vertical plates 2-2, and the two contact wheels 1 -7 line contacts on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com