Mounting structure of fabricated modular wallboard

An installation structure and modularization technology, which is applied in building structure, covering/lining, construction, etc., can solve the problems of complex construction of wide wall panels, uncontrollable installation quality, low efficiency, etc., and achieve good installation effect and difficult maintenance and cost reduction, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

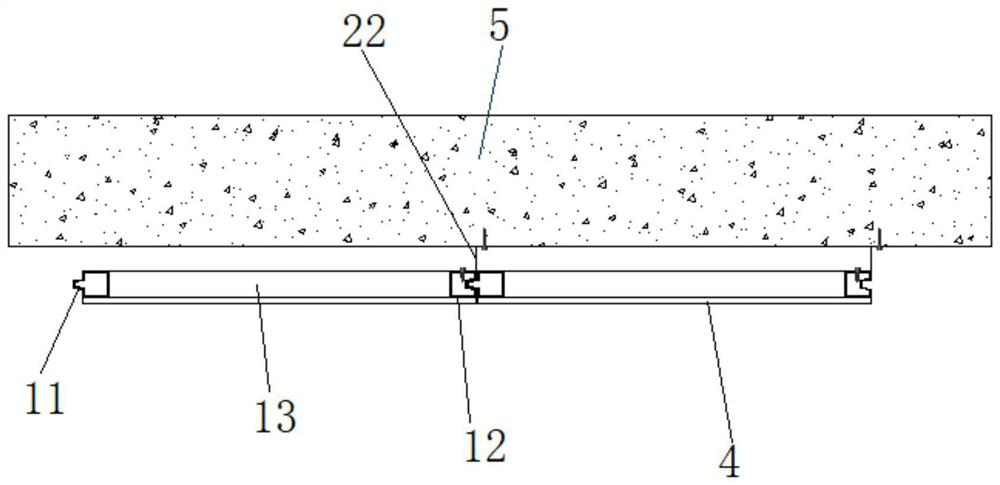

[0038] see Figure 1 to Figure 3 , the figure shows an installation structure of a prefabricated modular wall panel provided by Embodiment 1 of the present invention, which mainly includes: a connecting frame, which includes a first vertical frame 11, a second vertical frame 12 and a Between the horizontal frame 13, the two ends of the horizontal frame 13 are respectively connected to the first vertical frame 11 and the second vertical frame 12, the first vertical frame 11 and the second vertical frame 12 are parallel, and the horizontal frame 13 is connected to the first vertical frame 11, The second vertical frame 12 is vertically arranged; along the height direction of the first vertical frame 11 and the second vertical frame 12, the horizontal frame 13 is arranged as a plurality of parallel ones; the connecting assembly includes a first connecting piece 21 and a second connecting piece 22. The first connecting piece 21 connects the horizontal frame 13 with the first vertic...

Embodiment 2

[0047] see Figure 3 to Figure 5 , the figure shows the installation structure of a prefabricated modular wall panel provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first One vertical frame 11 is a convex frame, the second vertical frame 12 is a concave frame, and the horizontal frame 13 is a square frame; adjacent connecting frames are connected by the protrusion 111 of the first vertical frame 11 and the groove 121 of the second vertical frame 12. stitching. Through the setting of the above structure, two adjacent modular wall panels can be quickly positioned and spliced, improving the construction efficiency, and the dislocation phenomenon is not easy to occur after installation, and the installation accuracy is high.

Embodiment 3

[0049] see figure 1 , image 3 , Figure 7 to Figure 8 , the figure shows the installation structure of a prefabricated modular wall panel provided by the third embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the first A connecting piece 21 is an "L" type connecting plate; the second connecting piece 22 is a "Z" type connecting plate; the corner of the second connecting piece 22 is a right angle; the first connecting piece 21 is provided with a first screw 211, the second A second screw 221 is disposed on the second connecting member 22 . Through the setting of the above structure, the first connecting member 21 and the second connecting member 22 are respectively fixed and connected by the first screw 211 and the second screw 221 , which greatly improves the connection strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com