Food processing cabinet capable of automatically managing internal microclimate

An automatic management and micro-climate technology, which is applied in food preservation, food science, meat/fish preservation, etc., can solve the problem of large fluctuations in temperature and humidity, the inability to realize fermented meat products, and the inability to meet the climate requirements of fermented meat products, etc. problems, to achieve uniform temperature distribution, stable and efficient refrigeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solutions and advantages of the embodiments of the present disclosure clearer, the technical solutions of the embodiments of the present disclosure will be clearly and completely described below in conjunction with the accompanying drawings of the embodiments of the present disclosure. In order to maintain the following description of the embodiments of the present disclosure For clarity and conciseness, the present disclosure omits detailed descriptions of known functions and known components to avoid unnecessarily obscuring the concepts of the present invention.

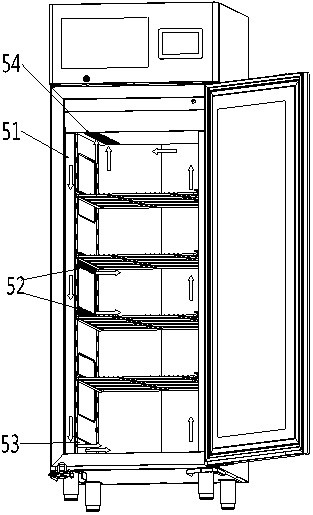

[0025] see Figure 1-5 , a food processing cabinet that automatically manages the internal microclimate, comprising a cabinet body 1, a steam assembly 2, a ventilation device 3, and an electric damper 4 are installed on the top of the cabinet body 1, and the inside of the cabinet body 1 is provided with a fan A field system 5 and a support 6, a control assembly 7 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com