Insertion element with adhesive ring, assembly, lens interface, camera, and manufacturing method

A lens interface and component technology, which is applied in the field of manufacturing such insert components and cameras, can solve the problems of polluting recording media, assembly and disassembly troubles, etc., and achieve the effects of reducing inspection and cleaning work, simplifying manufacturing, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

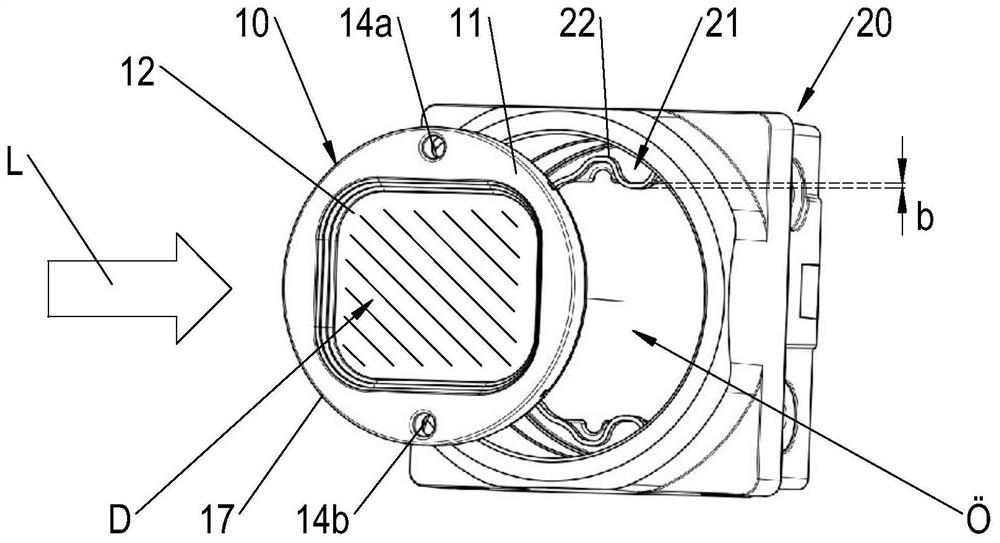

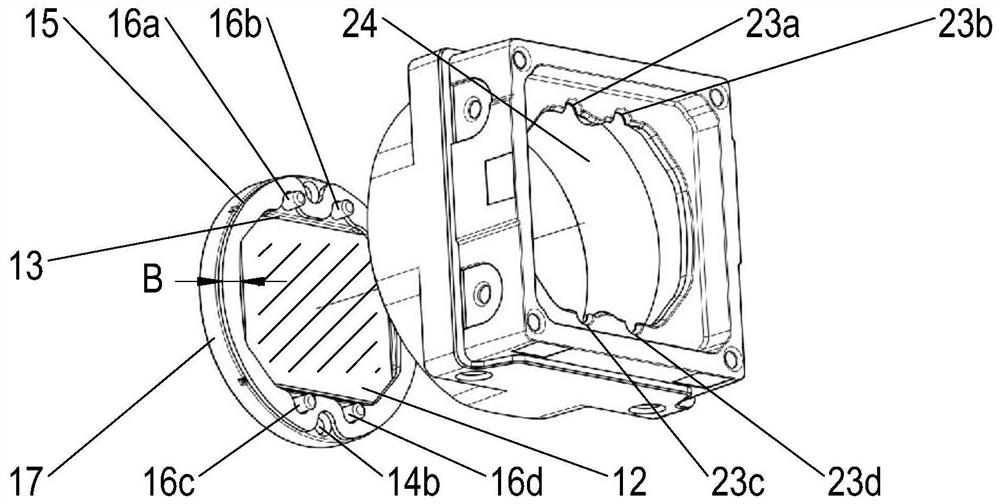

[0083] exist Figure 1a shows an embodiment of the insertion element 10 according to the invention in a perspective view before being inserted into the object connector 20 according to the invention. The viewing direction is from obliquely forward, so that in particular surfaces facing the lens can be seen.

[0084] and Figure 1b The same combination of lens mount 20 and insertion element 10 is shown viewed obliquely from behind before insertion, so that in particular the surface intended to face the photosensitive recording medium can be seen.

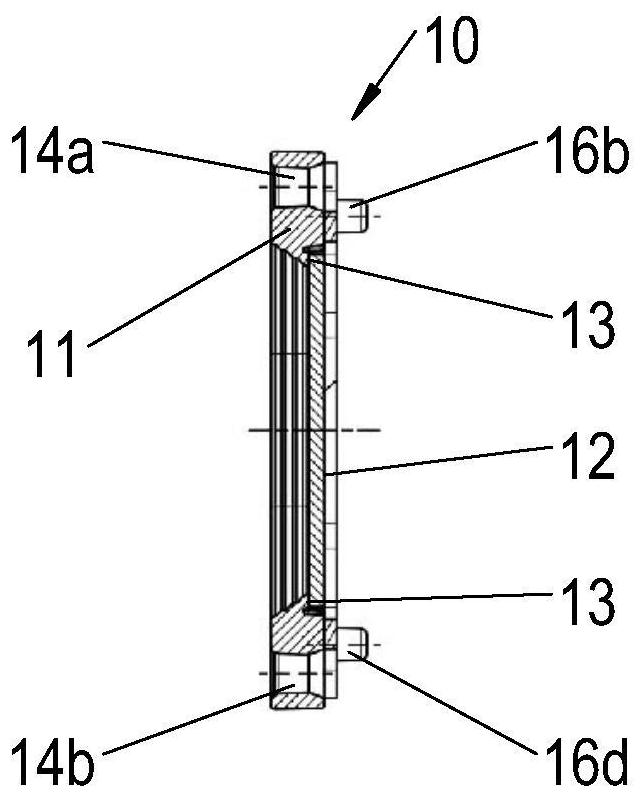

[0085] exist Figure 1c and 1d The insert elements 10 are shown in cross-section alone ( Figure 1c ) or inserted into the lens mount 20 ( Figure 1d ). Described below Figure 1a , 1b , 1c and 1d.

[0086] The insert element 10 comprises a frame element 11 which is designed in the present case as a filter holder and has a channel D for the provided beam path L. FIG. The frame element has a step 13 on its surface facing the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com