Quantitative evaluation method of aperture of porous membrane

A quantitative evaluation and porous membrane technology, which is applied in the field of quantitative evaluation of porous membrane pore size, can solve the problems of conventional molecular weight cut-off method, such as cumbersome operation and consumption of reagents, and achieve good application value, less reagent consumption and less operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

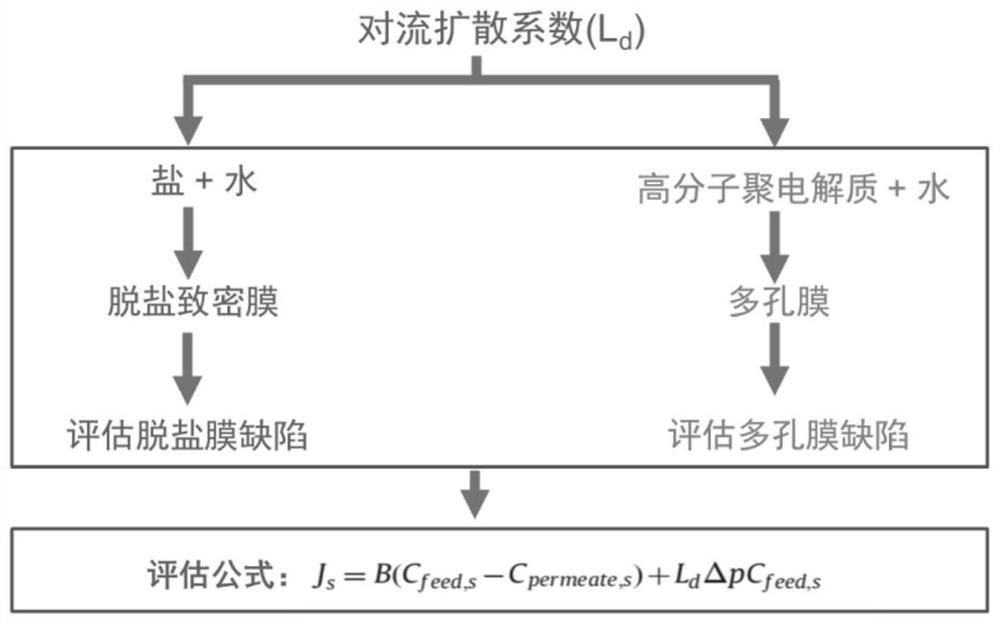

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

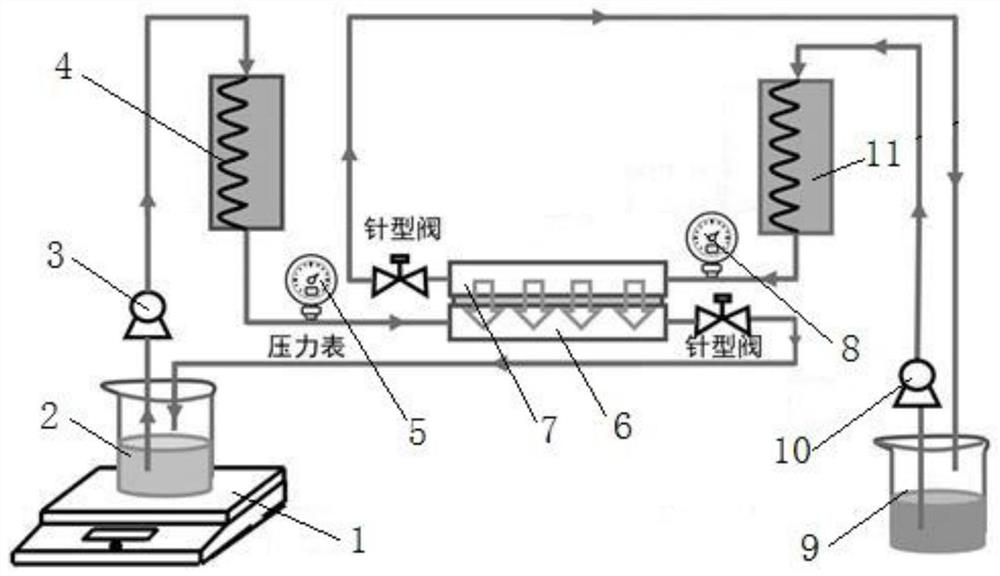

[0030] like figure 2 As shown, a quantitative evaluation device for the pore size of a porous membrane includes a membrane tank, a feed liquid tank 9, a permeate tank 2, a first gear pump 10, a second gear pump 3, a first pressure gauge 8, and a second pressure gauge 5 , the first conductivity meter, the second conductivity meter, the first temperature control system 11, the second temperature control system 4 and the electronic balance 1, the membrane pool is divided into the feed liquid side 7 and the permeation side 6 by the membrane material, and the feed liquid side 7. The first gear pump 10 and the feed liquid tank 9 form a feed liquid circulation loop. The permeate side 6 forms a permeate circulation loop through the second gear pump 3 and the permeate tank 2. In the feed liquid tank 9 and the permeate tank 2, respectively, Set the first conductivity meter and the second conductivity meter, the first pressure gauge 8 and the first flow meter are placed on the pipeline ...

Embodiment 2

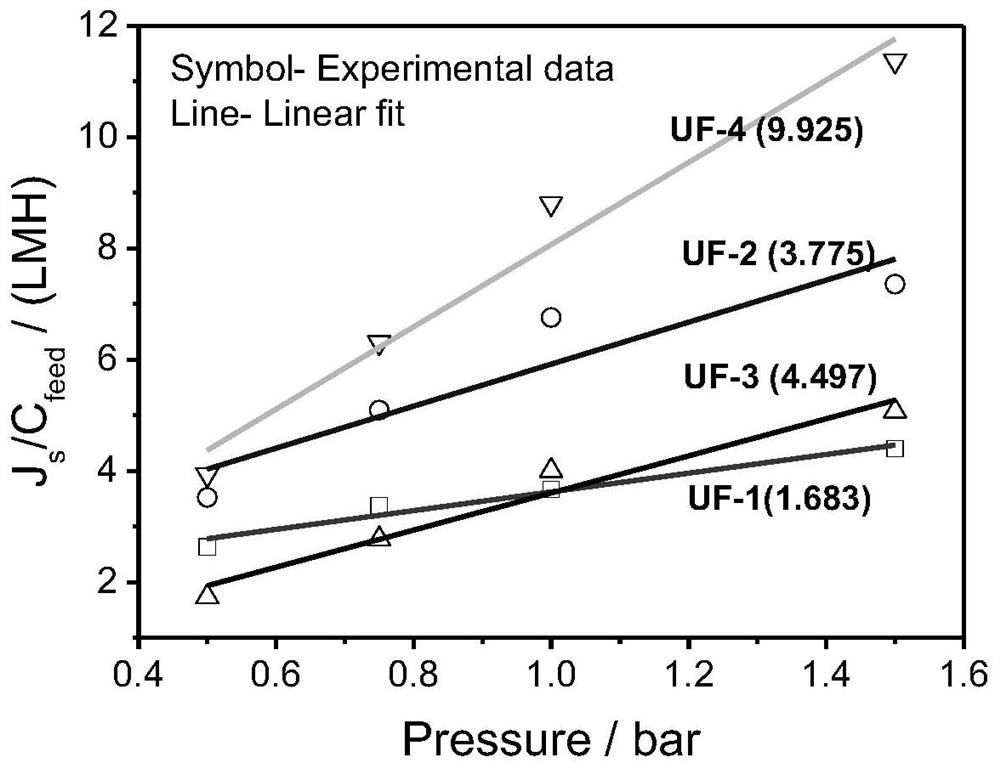

[0037] Choose the 2 micron CA water-washed cellulose acetate membrane as the base membrane, filter the multi-walled carbon nanotube dispersion liquid modified by dopamine on its surface, and filter 1, 3, 4, 5 ml respectively (marked as CNT-1, CNT-2, CNT-3, CNT-4), after standing and drying, the molecular weight cut-off method was used to measure the molecular weight cut-off as 57000, 25000, 20000 and 10000 Da respectively. In the same way, the ratio (Js / C feed,s ),As shown in table 2. Take the operating pressure as the abscissa, and J s / C feed,s Values are plotted on the ordinate (such as Figure 4 shown), the convective permeability coefficients of different ultrafiltration membranes can be obtained by using the least square method, and PC-1, PC-2, PC-3, and PC-4 correspond to 5.413LMH / bar, 4.20LMH / bar, and 3.83LMH respectively / bar and 3.67LMH / bar. Linear fitting of the molecular weight cut off and the convective diffusion coefficient, it can be found that the two ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com