Boiler outlet flue structure with ash removal hole

A technology of outlet flue and ash cleaning hole, which is applied in the direction of solid residue removal, combustion method, lighting and heating equipment, etc., and can solve problems such as excessive dust, time-consuming and labor-intensive cleaning, and inconvenient development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

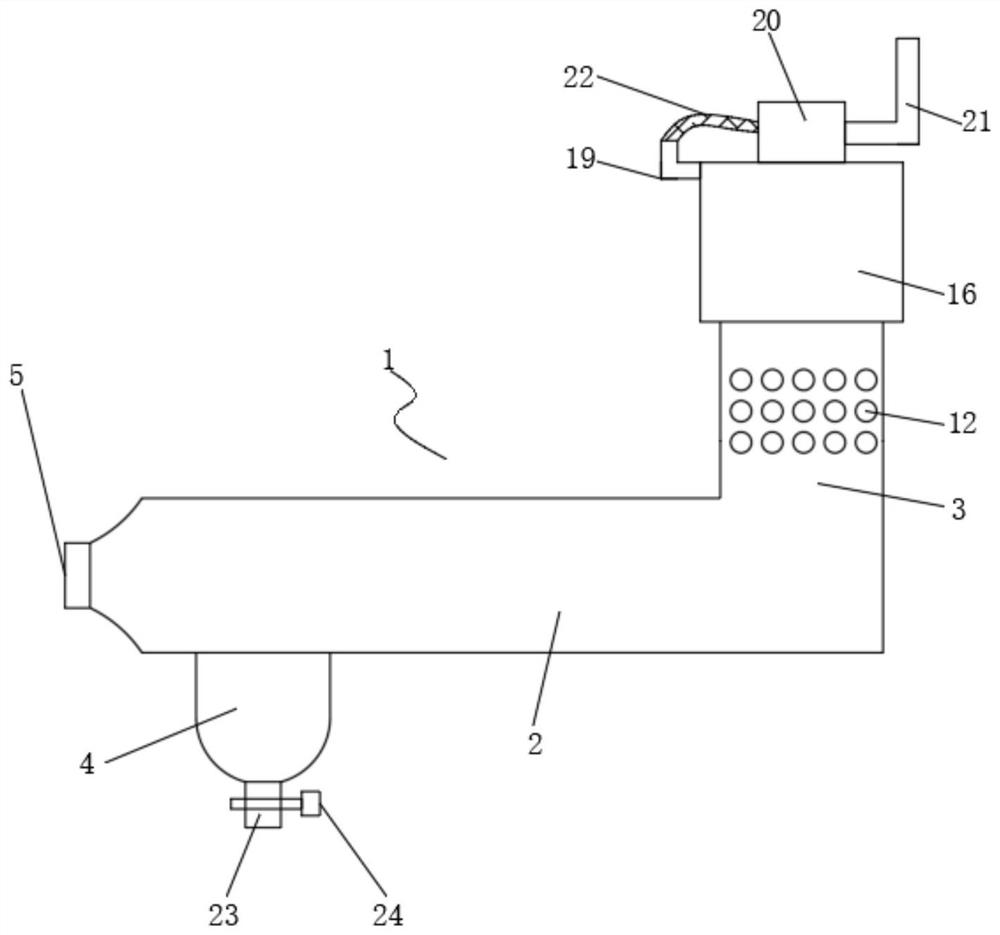

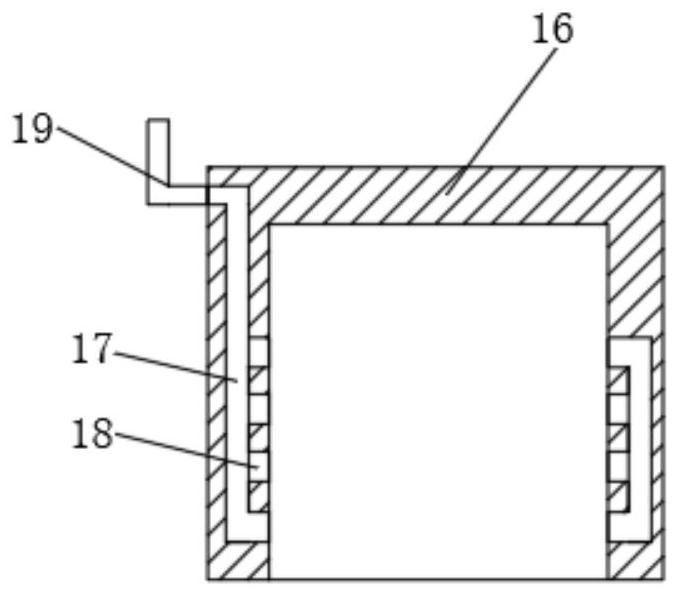

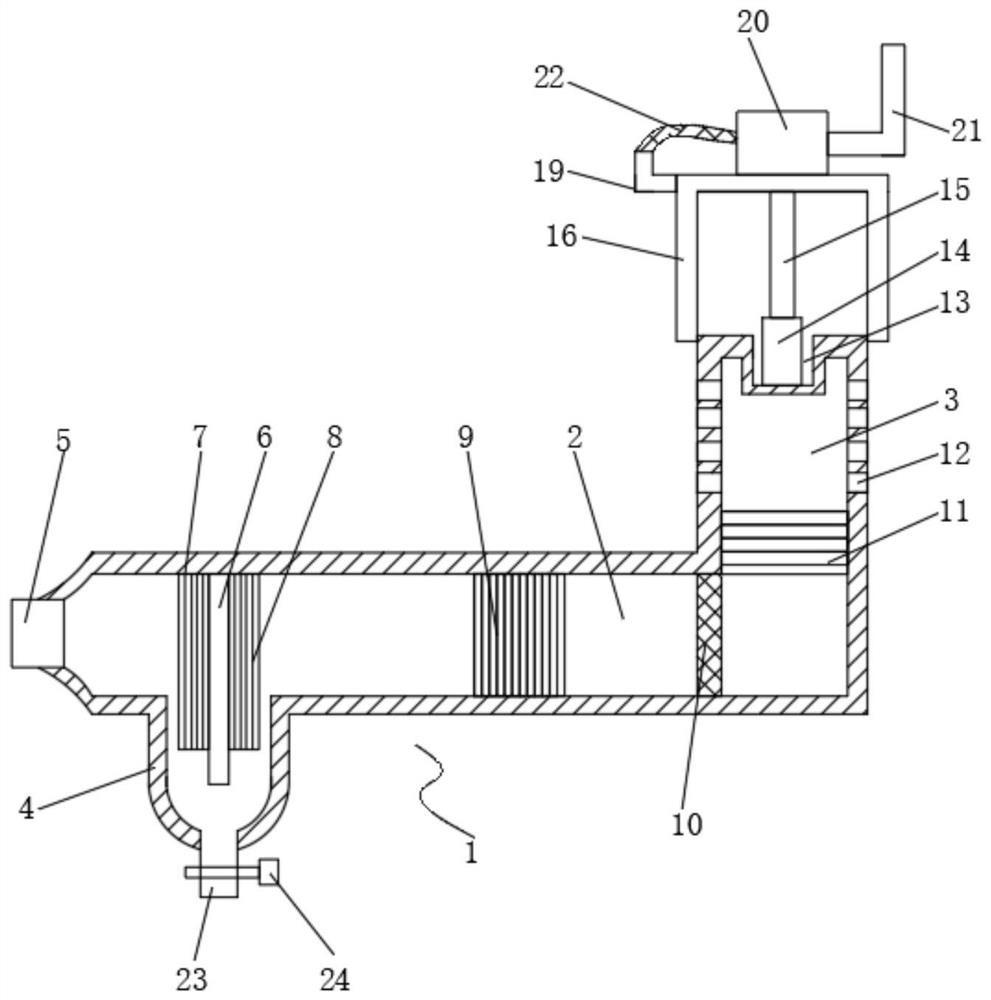

[0028] Such as Figure 1-4 As shown, the embodiment of the present invention provides a boiler outlet flue structure with soot cleaning holes, including a flue body 1, the flue body 1 includes a first pipe 2, a second pipe 3, a third pipe 4, the first The end of the pipe 2 communicates with the second pipe 3, the third pipe 4 is located below the first pipe 2, and the third pipe 4 communicates with the first pipe 2, which is convenient for the flow of smoke and dust, and then forms the deposition of smoke and dust. The inner top of the pipe 2 is fixedly installed with a water-cooled wall 6. When the smoke is exhausted, it encounters a surface with a lower temperature to make small particles condense on the pipe wall to form dust accumulation. The inner top of the first pipe 2 is located at the water-cooled wall 6 A high-temperature reheater 7 is fixedly installed on the left side, a final superheater 8 is fixedly installed on the inner top of the first pipeline 2 and on the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com