Carding machine with device for detecting interfering particles

A carding machine and particle technology, which is applied in the field of carding machines, can solve the problems of easy failure and consumption, and achieve the effects of avoiding failure, long service life and shortening downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

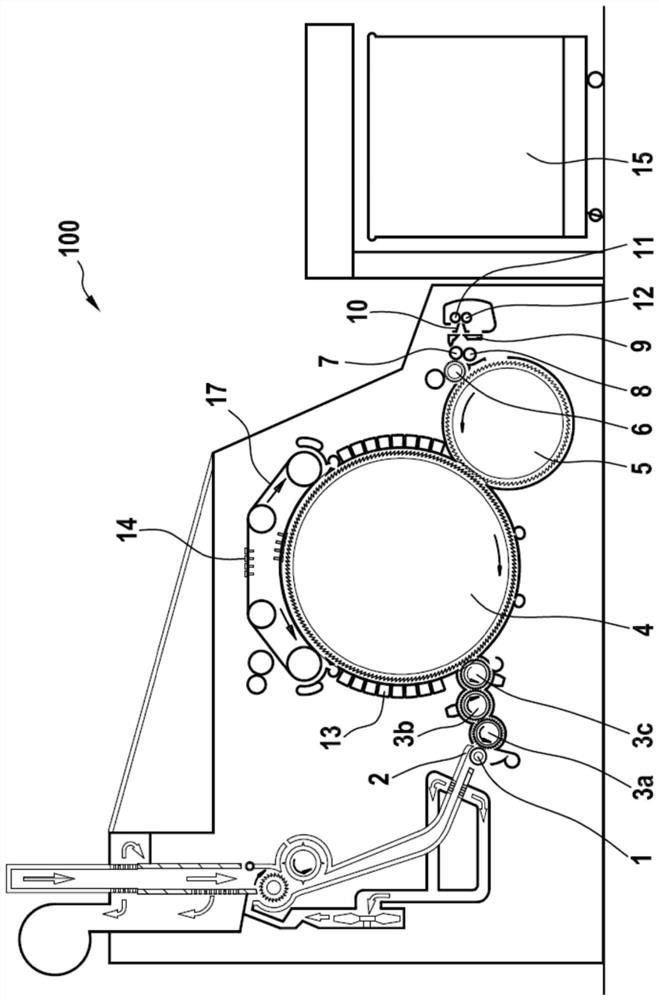

[0023] figure 1 A card 100 according to the prior art is shown in which the fiber bundles are guided through channels to a feed roller 1 , a feed plate 2 , through a plurality of licker-in rollers 3 a , 3 b , 3 c to a drum 4 or cylinder. On the drum 4, the fibers of the fiber bundles are decomposed by means of fixed carding elements 13, deflation hoods and chopping knives, as well as by means of carding elements arranged in circulation on a revolving flat system 17 and formed as flat strips 14. The fibers are parallelized and cleaned. The resulting fibrous web 16 is then transported via a doffer 5, stripping rollers 6 and a plurality of squeeze rollers 7, 8 to a web guiding element 9, which converts the fibrous web into fibers by means of a web collecting bell 10. The fiber strips are transferred to subsequent processing equipment or cans 15 via detaching rollers 11 , 12 . The flat strip 14 and the carding elements 13 are adjusted relative to the cylinder 4 (carding nip) by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com