Continuous annealing cold-rolled carbon steel for stamping and preparation method thereof

A technology of cold-rolled carbon steel and continuous annealing, applied in the field of continuous annealing cold-rolled carbon steel for stamping and its preparation, can solve the problems that the surface of stamping parts cannot meet the use requirements, the quality requirements of automobile outer panels, and rough stamping, etc. Achieve the effects of fine and uniform structure of the finished product, good formability, and increase the strength of the strip steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

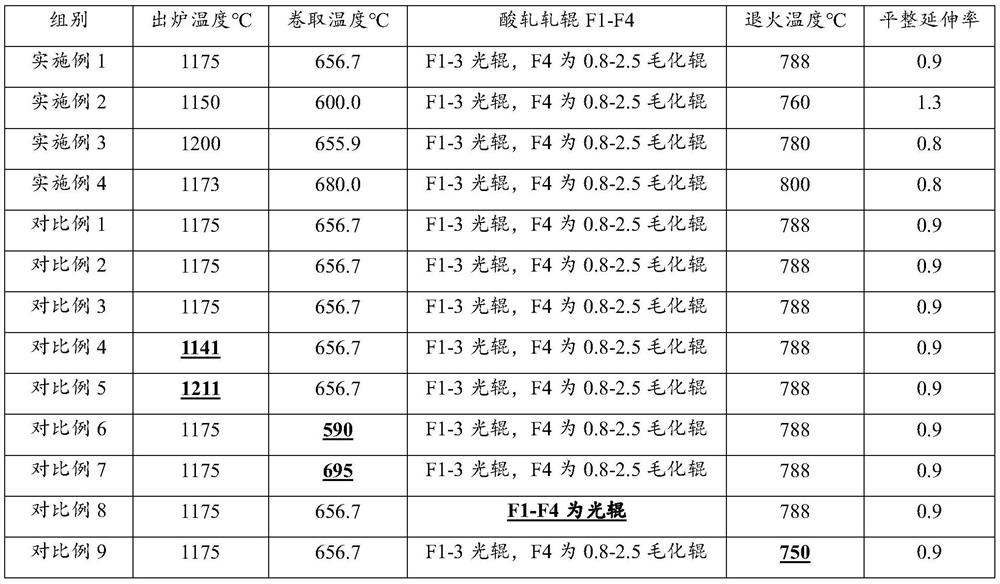

[0045] The present invention also provides a preparation method of the continuous annealing cold-rolled carbon steel for stamping, the preparation method comprising:

[0046] Obtain the cast slab of continuous annealing cold-rolled carbon steel for stamping;

[0047] The slab is heated before rolling, hot rolled, cooled after rolling, coiled, pickled, cold rolled, annealed and leveled to obtain continuous annealed cold rolled carbon steel for stamping,

[0048] The heating temperature before rolling is 1150-1200°C, the coiling temperature is 600-680°C,

[0049] The hot rolling includes rough rolling and finish rolling,

[0050] In the pickling, the pickling F1-F3 grinds smooth rolls, and the F4 frame uses textured rolls with a roughness of 0.8 to 2.5 μm.

[0051] The annealing temperature of the annealing is 760-800°C,

[0052] The flat elongation is 0.8-1.3%.

[0053] The preparation method of the continuous annealing cold-rolled carbon steel for stamping provided by the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com