A helicopter rigid rotor hub

A rotor hub and helicopter technology, applied to propellers, rotorcraft, motor vehicles, etc., can solve problems such as the deviation of the natural frequency of the rotor from the design value, change the dynamic characteristics, and reduce the overall stiffness of the rotor, so as to achieve small elastic deformation and improve flapping frequency and shimmy frequency, effect of guaranteed flapping stiffness and shimmy stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

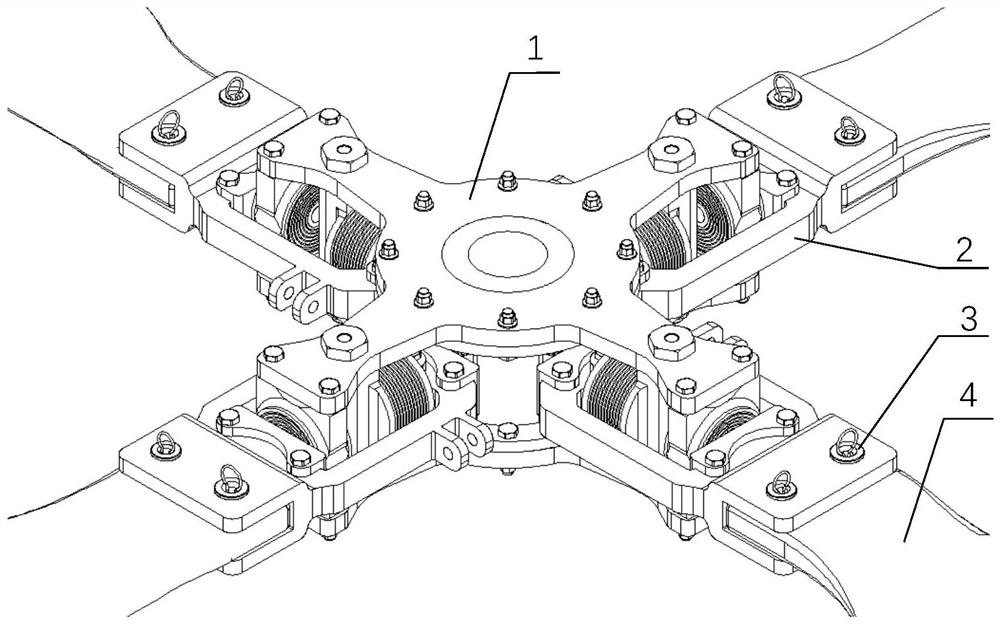

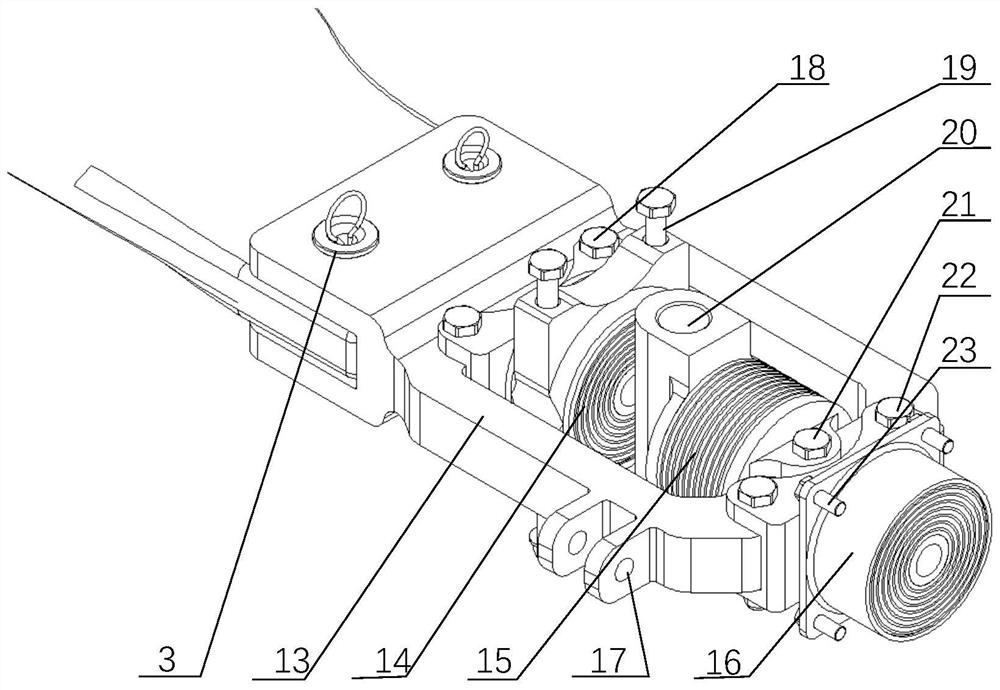

[0021] combine Figure 1-Figure 4 , a helicopter rigid rotor hub of the present invention, comprising a center piece module 1, a pitch variable arm module 2, a blade mounting pin 3 and a blade 4;

[0022] The blade 4 is installed on the pitch-changing arm module 2 through the blade mounting pin 3 , and four pitch-changing arm modules 2 are evenly distributed around the center piece module 1 to form a whole hub.

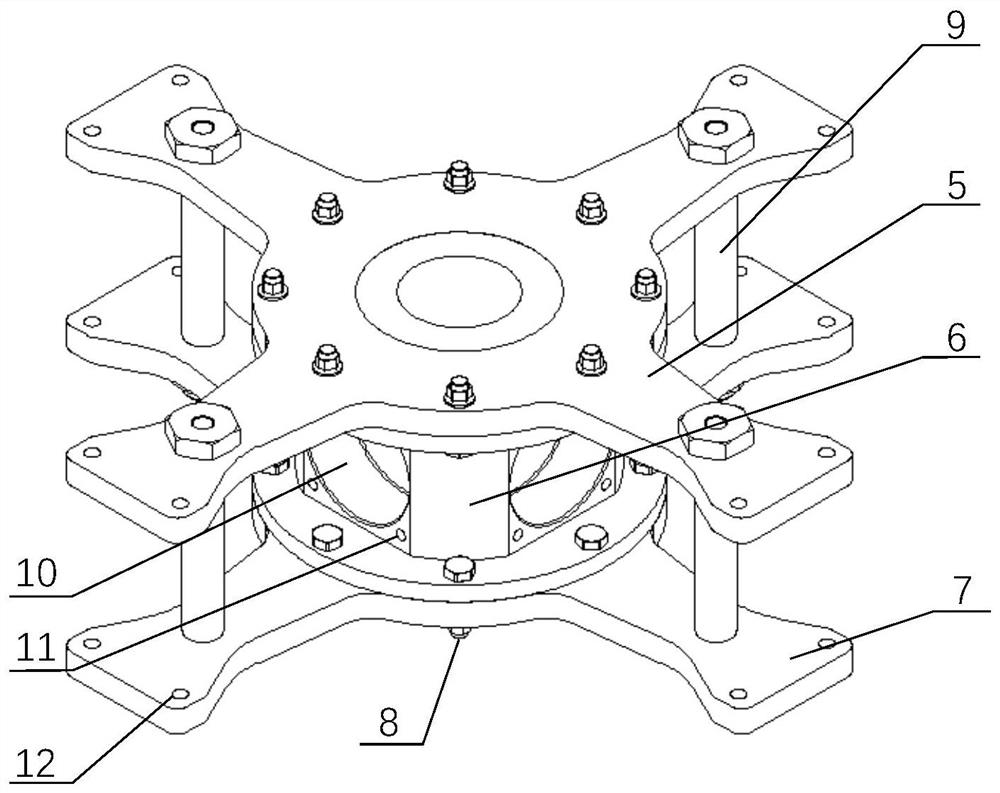

[0023] combine figure 2 , the center piece module 1 is the center of the propeller hub, which plays the role of connecting the pitch-changing arm module 2 and the rotor shaft, and is composed of an upper splint 5, a center piece 6, a lower splint 7, tightening bolts 8 and large bolts 9. The central part 6 is fixed between the upper splint 5 and the lower splint 7 by tightening bolts 8; four cylindrical grooves 10 are evenly distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com