Preheating annular cutting device for aluminum-plastic composite pipe

An aluminum-plastic composite pipe and preheating ring technology, which is applied in metal processing and other directions, can solve the problems of separation of three-layer pipes, affecting the quality of pipes, and insufficient sealing quality in terms of stability in terms of continuity of material guide, so as to achieve the effect of ensuring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

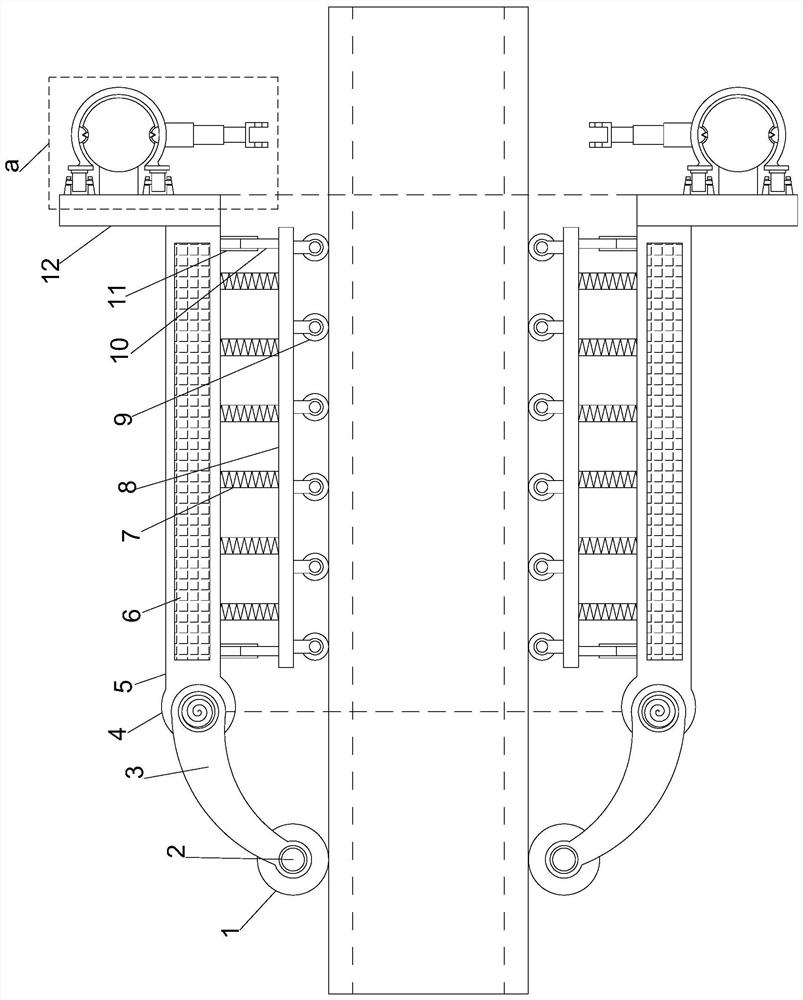

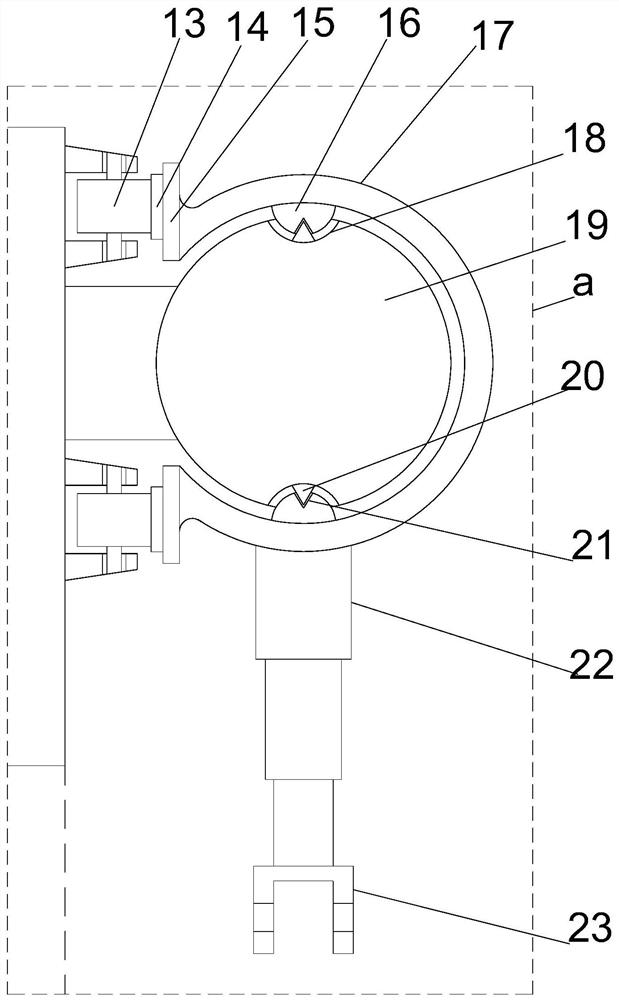

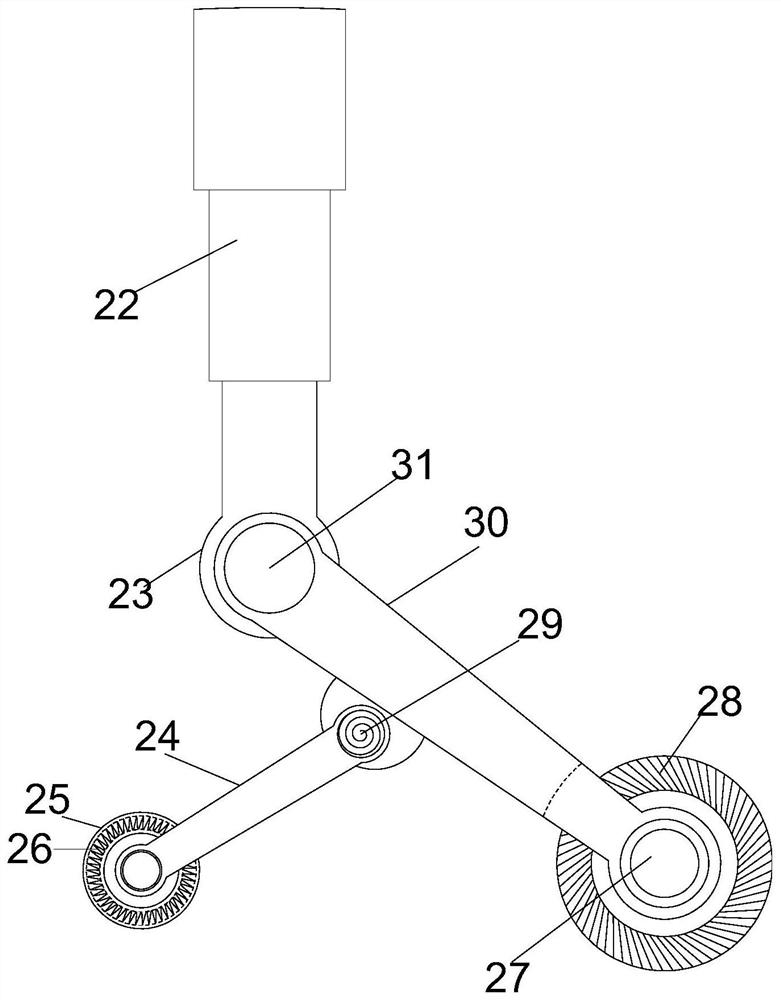

[0022] see Figure 1~4 , in an embodiment of the present invention, a preheating ring cutting device for aluminum-plastic composite pipes includes a horizontally arranged support installation cylinder 5, and a plurality of rotating installation frames 4 are arranged at equal angles on the left end of the support installation cylinder 5, and the rotation installation frames 4 are uniformly The left side is provided with a swing mounting plate 3, one end of the swing mounting plate 3 is connected to the rotating mounting frame 4 through the reset shaft 29, and the other end of the swing mounting plate 3 is provided with a moving guide wheel 1 through the driving shaft 2, and the supporting mounting cylinder The right end of the 5 is provided with a ring-shaped mounting plate 12, and a plurality of storage batteries 6 are embedded at an equal angle in the cylinder wall of the supporting installation cylinder 5, and a plurality of displacement guide plates 8 are arranged at an equa...

Embodiment 2

[0025] On the basis of Embodiment 1, under the action of the displacement spring 7, cooperate with the displacement guide column 10 and become the guide cylinder, so that the guide wheel 9 on the displacement guide plate 8 can always be aligned with the aluminum-plastic composite pipe. Contact to achieve stable continuous material guide, through the cooperation of the limit rotation ring 16 and the limit rotation groove 18, the ring cutting rotation is more stable, and the rotation conductive ring 20 and the rotation conductive groove 21 cooperate to make the power supply continuous and stable during the ring cutting process .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com