Assembling tool and assembling method for single-slit self-lubricating joint bearing

A technology for joint bearings and assembly tools, applied in manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of high mechanical forming difficulty, inability to adapt to bearings, complex structure, etc., achieve low mechanical processing difficulty, improve product quality, Processing simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

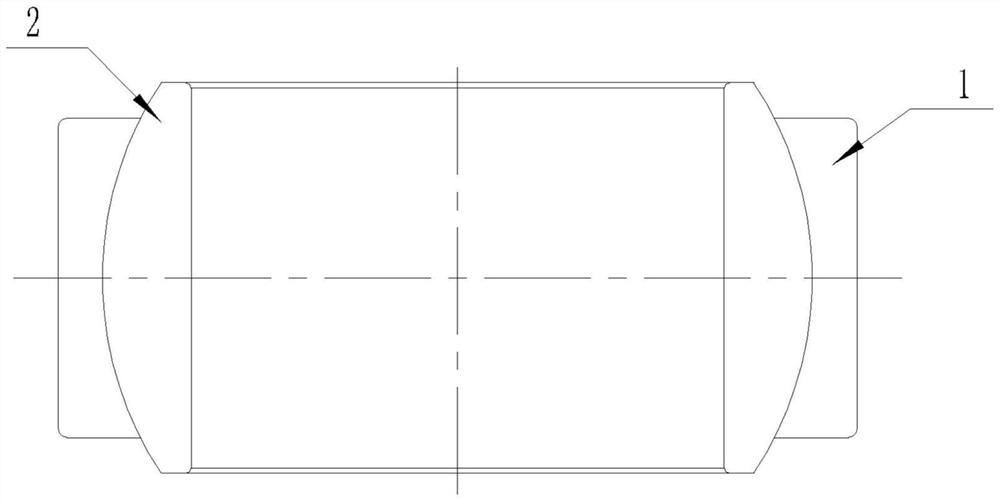

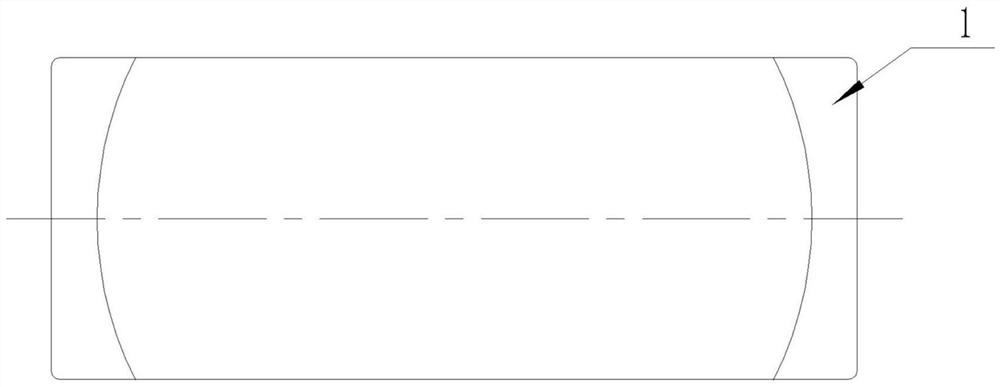

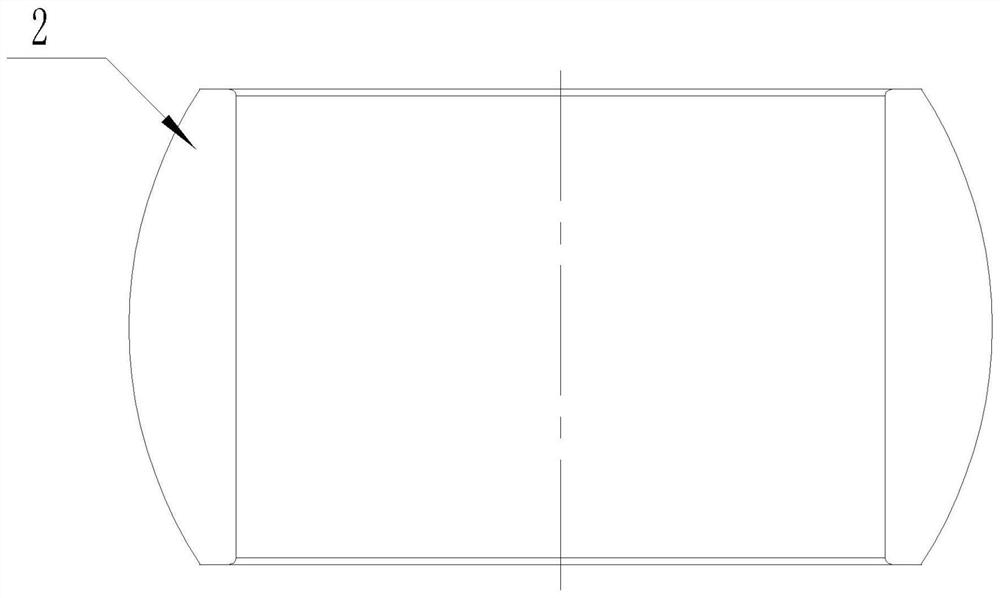

[0018] Example: see figure 1 — Figure 5 , an assembly tool for single-slit self-lubricating joint bearings, the upper part is tapered, and the cone angle is processed according to the bearing specification of 20°-30°, the width of the smallest cone angle is smaller than the smallest inner diameter of the bearing end face, and the largest cone angle The width is 5-8mm larger than the spherical surface diameter of the joint bearing; a long strip-shaped through groove 4 is processed in the radial direction of the taper of the assembly tool 3, the groove width is greater than the width of the inner ball 2 of the joint bearing, and the groove depth is the above-mentioned One-third of the diameter of the inner ball of the joint bearing; the assembly tool is made of 45# or 42CrMo material, and after heat treatment and quenching process, the hardness of the hardened layer should be greater than HRC60; the assembly tool must be used with the bracket 5. The bracket 5 is located direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com